Researchers Uncover Hidden Battery Flaw Behind Short Lifespan and Fire Hazards

“Until now, attempts to transition to single-crystal cathodes largely followed the same design principles used for polycrystalline ones,” said Wang, a postdoctoral researcher at UChicago and Argonne. “Our study shows that the primary degradation mechanism in single-crystal particles differs from that in polycrystals, which means their composition requirements must also be different.”

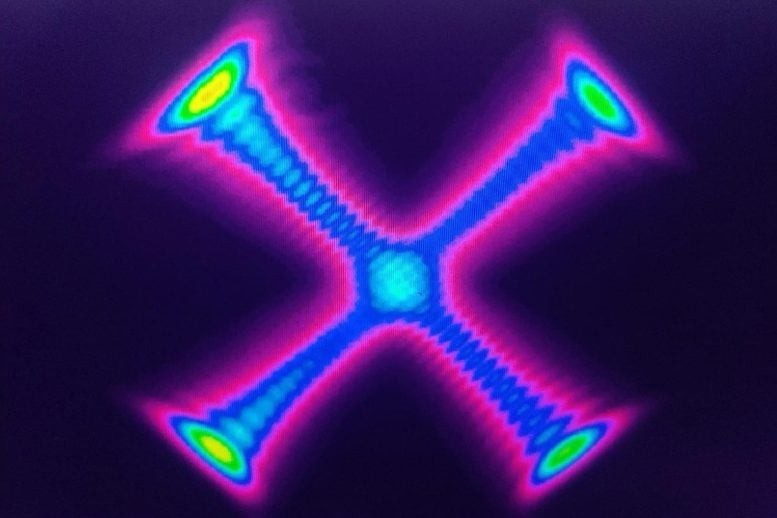

Figure 1. Hidden Battery Defect Revealed: Shorter Life and Increased Fire Risk.

The research not only challenges conventional design approaches but also reevaluates the roles of cobalt and manganese in battery mechanical failures. Figure 1 shows Hidden Battery Defect Revealed: Shorter Life and Increased Fire Risk.

“Advancing single-crystal cathode batteries will require both new design strategies and different materials,” said Meng, director of the Energy Storage Research Alliance (ESRA) at Argonne. “By understanding how various cathode materials degrade, we can develop a suite of high-performance cathodes to meet global energy demands.”

A Cracking Mystery

In polycrystal cathode batteries, charging and discharging cause tiny, stacked particles to swell and shrink. This repeated expansion and contraction can widen the grain boundaries separating the crystals—much like how repeated freezing and thawing creates potholes in city streets.

If cracks widen too much, electrolyte can seep in, triggering unwanted chemical reactions and oxygen release, which raise safety risks such as thermal runaway. More commonly, though, these cracks lead to gradual capacity loss, reducing the battery’s ability to hold a charge over time.

“We demonstrate that degradation in single-crystal NMC cathodes is dominated by a distinct mechanical failure mode,” said Tongchao Liu, a chemist at Argonne. “Identifying this previously overlooked mechanism links material composition directly to degradation pathways, offering deeper insight into performance decay.”

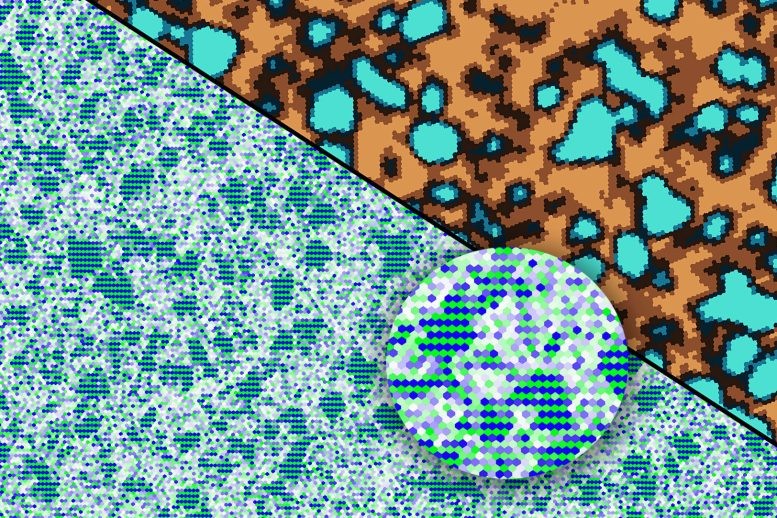

Using multi-scale synchrotron X-ray techniques and high-resolution transmission electron microscopy, the team found that cracking in single-crystal cathodes stems from reaction heterogeneity. Particles react at different rates, causing strain within a single crystal rather than between multiple crystals as in polycrystal designs.

Different Solutions

Polycrystal cathodes balance nickel, manganese, and cobalt. While cobalt contributes to cracking, it also mitigates Li/Ni disorder.

By testing a nickel-cobalt battery (no manganese) and a nickel-manganese battery (no cobalt), the team discovered that in single-crystal cathodes, the effect flips: manganese is more mechanically harmful, while cobalt actually improves longevity.

Cobalt, however, is expensive. Wang says the next step is identifying cost-effective alternatives that replicate cobalt’s benefits.

“Advances come in cycles,” said Amine. “You solve one problem, then move on to the next. The insights from this collaborative work will help researchers at Argonne, UChicago PME, and beyond create safer, longer-lasting materials for the batteries of tomorrow.”

Source:SciTECHDaily

Cite this article:

Priyadharshini S (2025), Researchers Uncover Hidden Battery Flaw Behind Short Lifespan and Fire Hazards, AnaTechMaz, pp. 335