Airframe Designs Pioneers a Blended Approach to Tooling Design

With the growing adoption of additive manufacturing, our blended approach—combining traditional and additive design techniques—unlocks new opportunities through innovative thinking. By leveraging this hybrid method, we can efficiently deliver tailored solutions for specific applications with faster turnaround times.

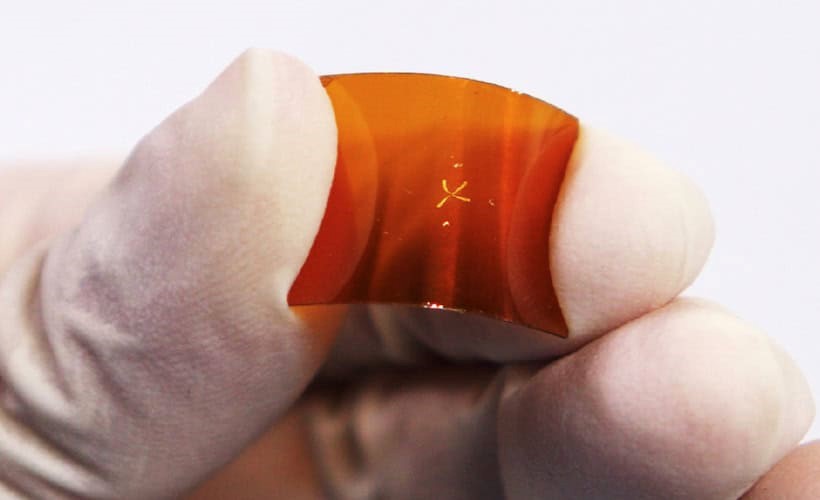

Figure 1. Airframe Designs Leads the Way with a Blended Tooling Design Approach

Our additive manufacturing department enables us to seamlessly integrate traditional tooling methods with cutting-edge additive processes. This capability was recently demonstrated for one of our Defence clients, where we provided lightweight, accurate, and cost-effective tooling in significantly reduced lead times compared to conventional methods. Figure 1 shows Airframe Designs Leads the Way with a Blended Tooling Design Approach

By combining our innovation and expertise, we offer a comprehensive turnkey solution encompassing digital design, stress analysis, and polymer additive manufacturing, integrated with our established traditional tooling supply chain.

Our tooling design capabilities continue to expand across major sectors, including Aerospace, Defence, Marine, and Space. We specialize in a variety of tools, such as detail and assembly fixtures, jigs, drill, rout and trim fixtures, composite hand layup mould tools, lifting and handling equipment, and transport solutions.

Serving a diverse client base, we employ advanced CAD software, including Catia, SolidWorks, and Siemens NX. Alongside our CAD expertise, we provide comprehensive documentation to ensure CE Marking compliance for tooling products.

Using hand-scanning technology, we reverse engineer legacy tools to create digital twins, offering customers an updatable dataset for lifecycle management and modification of existing tooling.

All our design activities are supported by our in-house stress analysis team, providing a full range of services from hand calculations to FEM analysis as needed.

Airframe Designs adheres to rigorous industry standards, holding certifications for ISO 9001, ISO 14001, ISO 27001, Cyber Essentials Plus, and JOSCAR accreditation.

Our commitment to blending traditional and modern methods reflects the core Airframe Designs ethos: delivering engineering excellence in every project.Our commitment to blending traditional and modern methods reflects the core Airframe Designs ethos: delivering engineering excellence in every project.

At the heart of our operations, we provide a full suite of services encompassing Design, Analysis, Certification, Additive Manufacturing, and 3D Scanning. Our organization is structured into three specialized teams: Stress Analysis, Design Engineering, and Additive Manufacturing.

To date, we have successfully delivered over 500 projects, collaborating with a diverse array of clients. With a collective expertise spanning more than five decades, we confidently address complex engineering challenges.

We take pride in our extensive knowledge and meticulous approach. Renowned for our proficiency, we are often trusted by clients to verify and validate engineering data, ensuring unparalleled accuracy and reliability.

Source:AZOMATERIALS

Cite this article:

Priyadharshini S (2024), Airframe Designs Pioneers a Blended Approach to Tooling Design, AnaTechMaz, pp. 84