Engineers Make CO2 Conversion into Useful Products More Practical

"New Electrode Design Enhances CO2 Conversion Efficiency into Useful Products"

Engineers at MIT have developed a new electrode design that boosts the efficiency of electrochemical reactions, turning carbon dioxide into valuable products like ethylene. With the growing need to capture CO2 and convert it into usable materials, this innovation promises to improve the practicality and economics of such processes. The research, led by MIT's Simon Rufer and Kripa Varanasi, highlights the potential for scaling up CO2 conversion technologies to address climate challenges.

"MIT Engineers Overcome Key Challenge in CO2 Conversion to Ethylene"

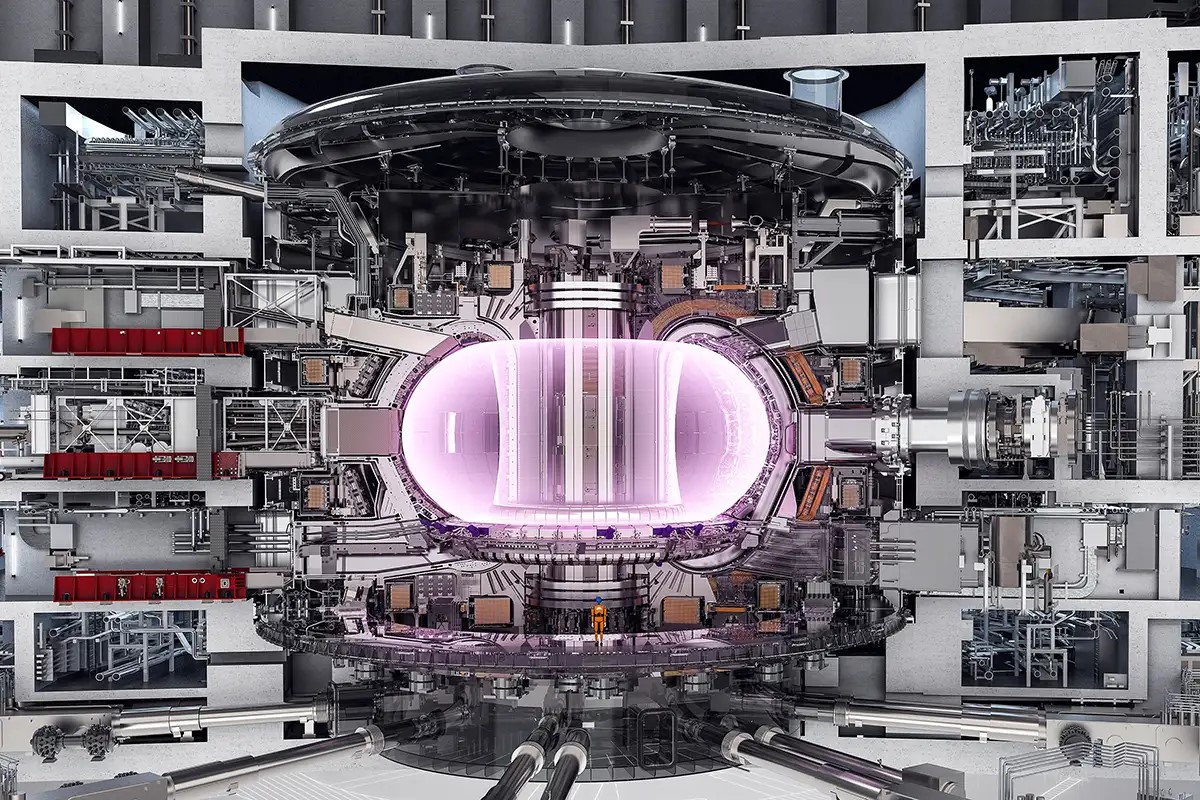

Figure 1. Engineers Enhance CO2 Conversion for Practical Use

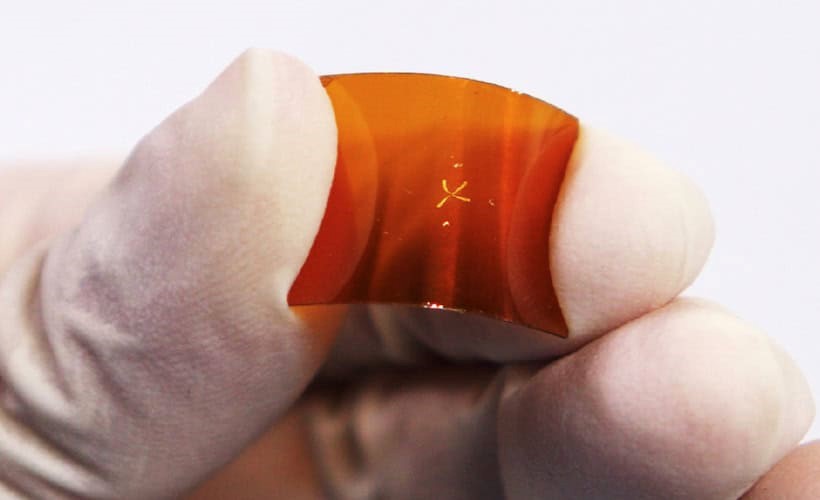

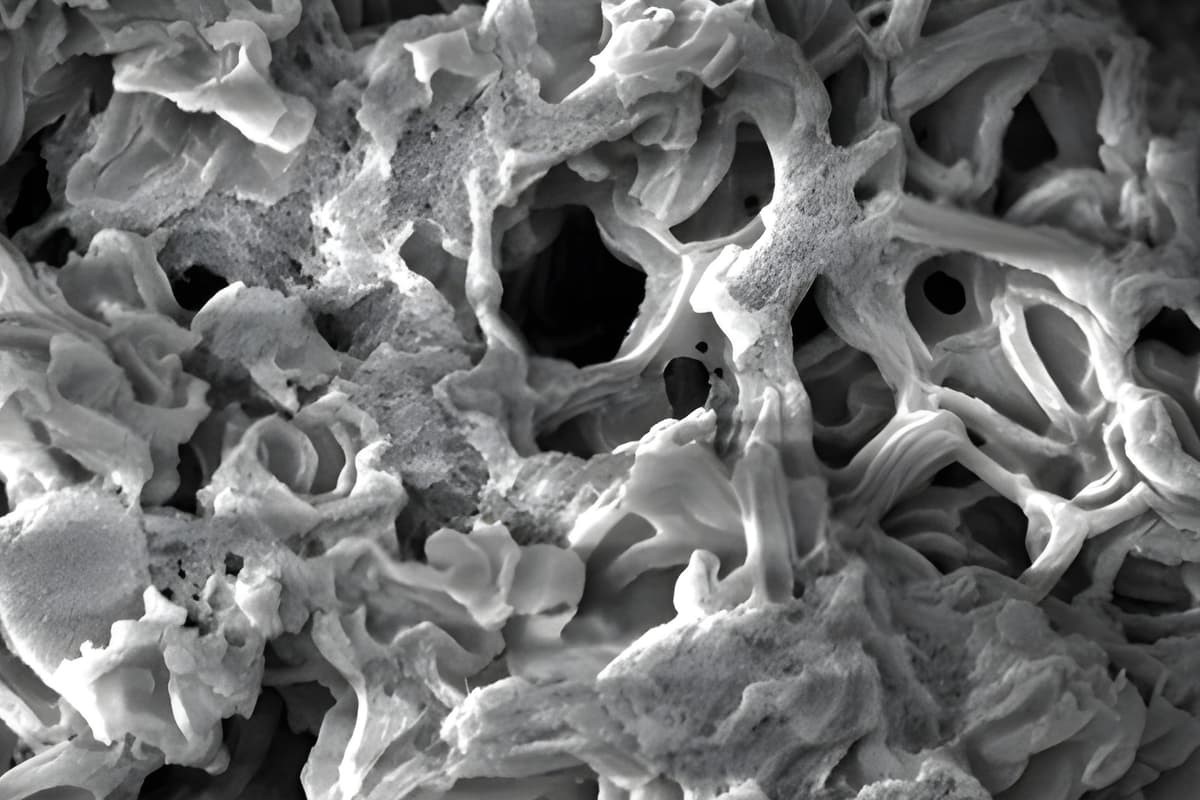

MIT engineers have developed a new approach to improve the efficiency and cost-effectiveness of electrochemical CO2 conversion to ethylene, a valuable chemical used in plastics and fuels. The team focused on optimizing gas diffusion electrodes, which play a critical role in the conversion process. By resolving the tradeoff between electrical conductivity and hydrophobicity, they have created an electrode design that boosts performance without compromising either property. This breakthrough could pave the way for more efficient CO2-to-ethylene processes, potentially lowering production costs and advancing sustainable chemical production. Figure 1 Shows Engineers Enhance CO2 Conversion for Practical Use.

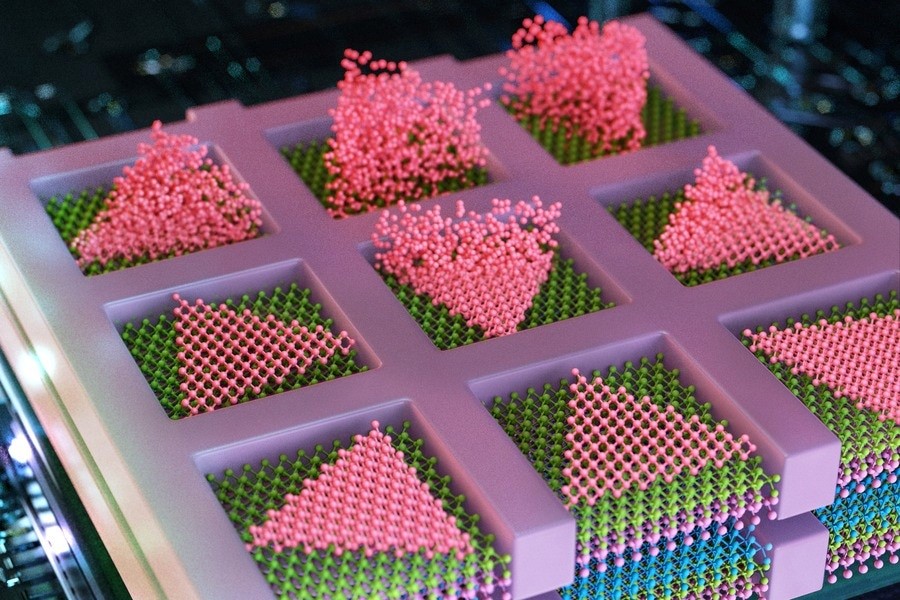

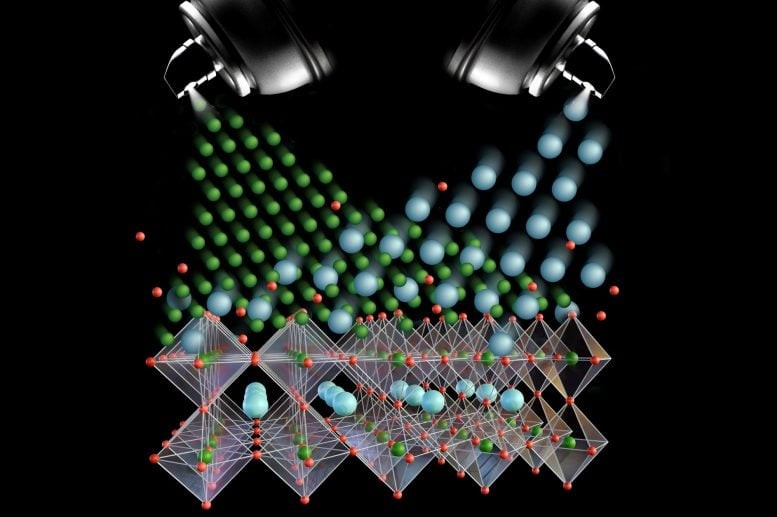

MIT engineers Simon Rufer and Kripa Varanasi have developed a simple yet effective solution to enhance the efficiency of electrochemical CO2 conversion systems. By incorporating conductive copper wires into PTFE (Teflon), they successfully addressed the challenge of balancing hydrophobicity and conductivity in gas diffusion electrodes. The new design allows for both efficient electron flow and water repellence, overcoming limitations of traditional materials.

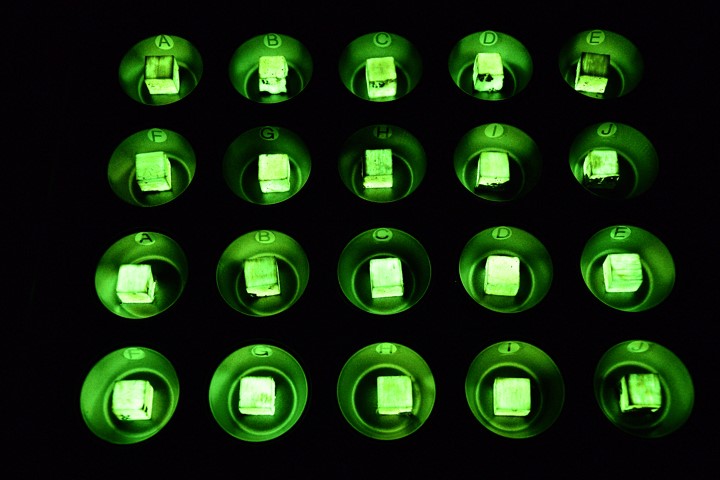

The team demonstrated this innovation on a larger scale, producing electrodes 10 times larger than typical lab-scale samples, and showed they maintained performance without significant voltage drop or unwanted byproducts. Their method, which involves weaving copper wire through the PTFE material, enables scaling up without compromising efficiency, making it adaptable for industrial use.

Rufer and Varanasi's approach can be integrated into existing manufacturing processes, offering a versatile solution for scaling carbon capture and conversion systems. Their research, supported by Shell through the MIT Energy Initiative, represents a critical step toward addressing the CO2 challenge at a global scale.

Source:MIT News

Cite this article:

Janani R (2024), Engineers Make CO2 Conversion into Useful Products More Practical, AnaTechMaz, pp. 77