Scientists Develop 3D Printing Technique That Makes Metal 20 Times Stronger

Unlocking the Potential of Vat Photopolymerization

Vat photopolymerization is a 3D printing process in which a light-reactive liquid resin is poured into a container and solidified layer by layer using a laser or ultraviolet light to create a 3D object. However, this approach is limited by its reliance on light-sensitive polymers, restricting the range of materials that can be fabricated.

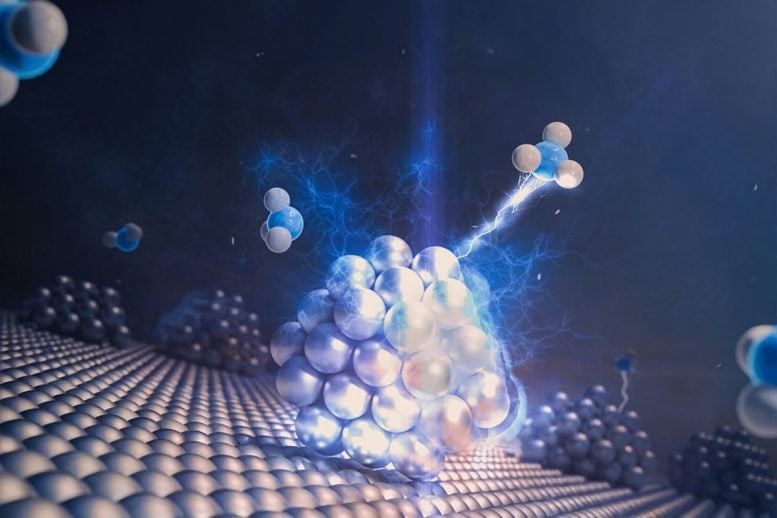

Figure 1. Scientists Unveil 3D Printing Breakthrough That Creates Metal 20× Stronger.

To expand these possibilities, some 3D printing techniques have attempted to convert printed polymers into metals or ceramics. Yet, as Daryl Yee, head of the Laboratory for the Chemistry of Materials and Manufacturing at EPFL’s School of Engineering, explains, the resulting materials often lack the desired quality. Figure 1 shows Scientists Unveil 3D Printing Breakthrough That Creates Metal 20× Stronger.

A Hydrogel Breakthrough for Metal and Ceramic Printing

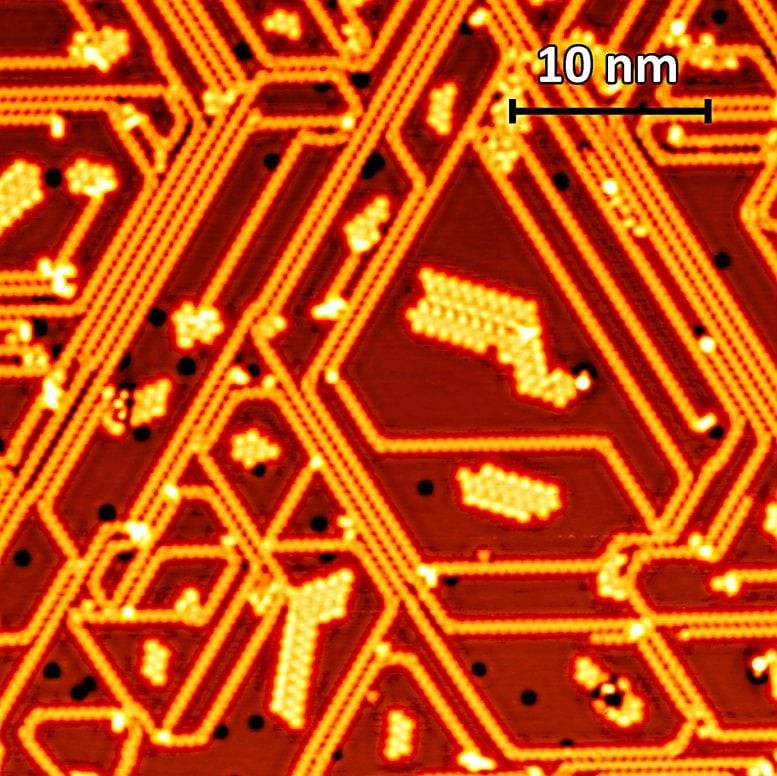

To address these challenges, Yee and his team have developed a novel method, detailed in their paper published in Advanced Materials. Rather than curing a resin already mixed with metal compounds, the researchers first 3D print a framework using a simple, water-based gel known as a hydrogel. This blank structure is then infused with metal salts, which are chemically transformed into tiny metal-containing nanoparticles that spread throughout the gel. By repeating the process several times, the researchers can increase the metal concentration and achieve stronger, denser materials.

After five to ten of these “growth cycles,” the remaining hydrogel is removed through heating, leaving behind a metal or ceramic structure that precisely replicates the original gel’s shape. The outcome is an exceptionally dense and durable object. Because the metal salts are introduced only after the printing step, a single hydrogel model can be transformed into a variety of metals, ceramics, or composite materials.

Targeting Advanced 3D Architectures

To demonstrate the potential of their approach, the team fabricated intricate mathematical lattice structures known as gyroids from iron, silver, and copper. These complex geometries showcased the method’s ability to create materials that are both mechanically robust and architecturally sophisticated.

To evaluate their performance, the researchers subjected the gyroid samples to increasing pressure using a universal testing machine—a device designed to measure a material’s strength and deformation under load.

Applications in Energy, Sensors, and Biomedicine

The researchers note that their technique is particularly promising for fabricating advanced 3D architectures that must be strong, lightweight, and geometrically complex—such as sensors, biomedical implants, and energy devices. For instance, metallic catalysts play a key role in facilitating reactions that convert chemical energy into electricity. Similarly, high-surface-area metals produced with this method could enhance cooling systems and energy storage technologies.

Looking ahead, the team aims to optimize the process for industrial scalability, focusing on increasing material density and improving production speed. While the repeated infusion cycles are vital for achieving high strength and precision, they currently make the process more time-consuming than conventional polymer-to-metal 3D printing techniques.

Source:SciTECHDaily

Cite this article:

Priyadharshini S (2025), Scientists Develop 3D Printing Technique That Makes Metal 20 Times Stronger, AnaTechMaz, pp. 287