“Superwood” — 50% Stronger Than Steel — Arriving This Year

Maryland-based startup Invent Wood is gearing up to mass-produce the first batches of ‘Superwood’, a groundbreaking material made from modified timber. This innovative wood is not only tougher than traditional barky stems but also outperforms steel in strength. The product is expected to hit the market later this year.

Figure 1. Superwood: Arriving This Year — 50% Stronger Than Steel.

Editor’s note: We often receive requests for updates on popular stories. This article was originally published in February 2018 and has now been re-edited and updated with the latest information as of May 2025. Enjoy! Figure 1 shows Superwood: Arriving This Year — 50% Stronger Than Steel.

The resulting Superwood is not only 50% stronger than steel but also resistant to fire, weathering, and pests. Hu has optimized the production process, reducing manufacturing time from weeks to mere hours, and licensed the technology to Invent Wood. The company has raised $15 million to build a factory and plans to ship its first batches this Northern Hemisphere summer.

Initially, Superwood will be used primarily for building facades, with future ambitions to expand into structural applications—potentially replacing some concrete and steel in durable construction.

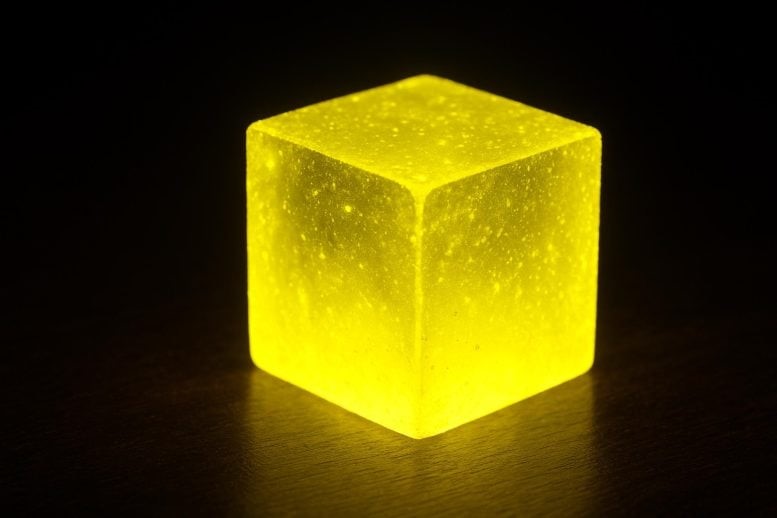

Over the past few years, Hu has pioneered innovations such as transparent wood, burnt-wood water filters, and sodium-ion batteries derived from wood and leaves.

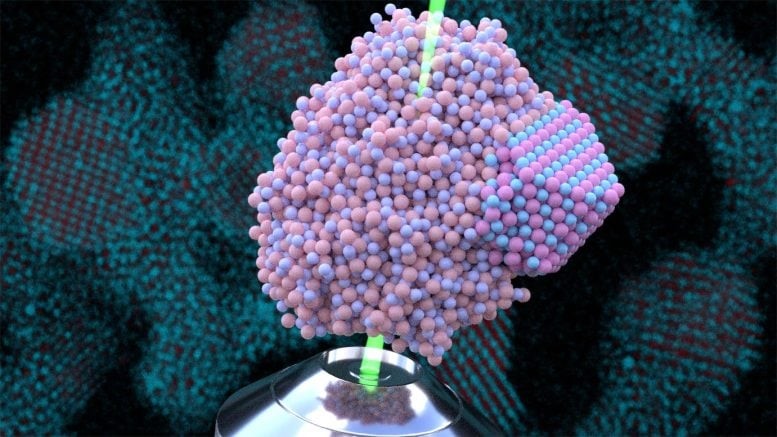

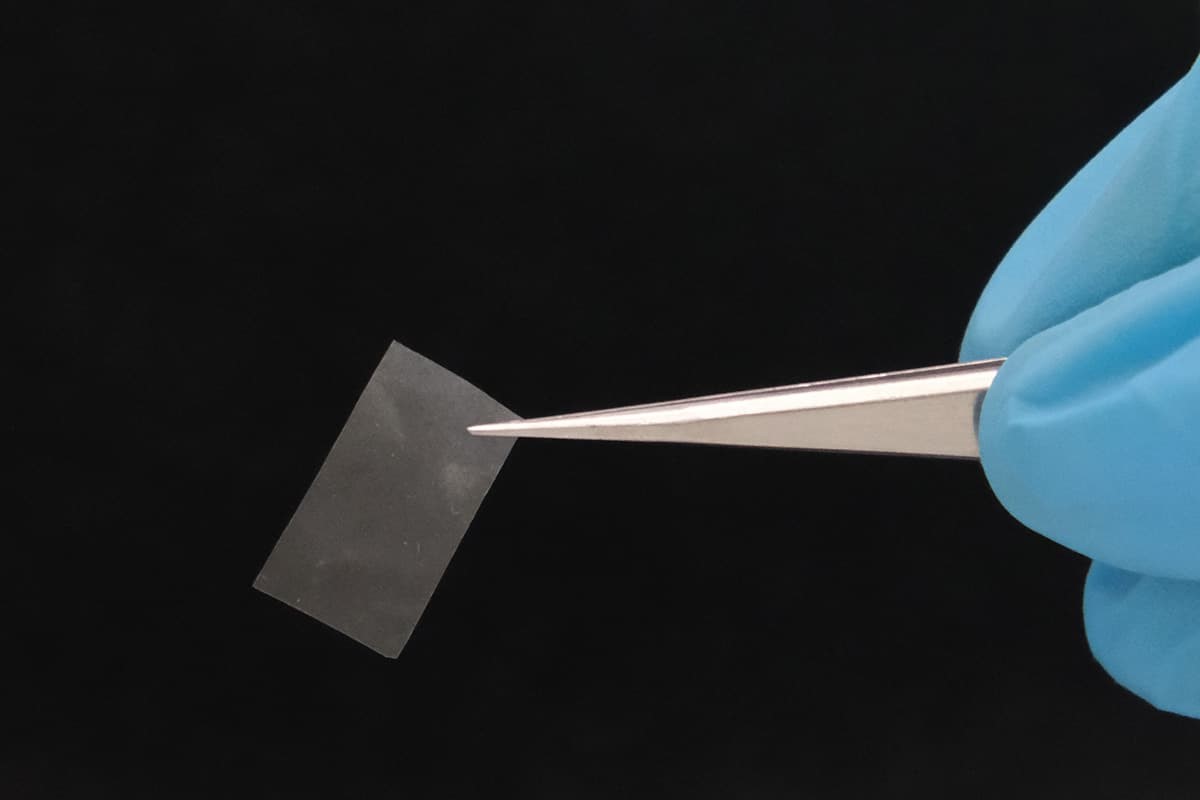

The exceptional strength of Superwood comes from a two-step process developed by Hu’s team. First, wood samples are boiled in a solution of sodium hydroxide and sodium sulfite, which partially removes lignin and hemicellulose. Next, the treated wood is hot-pressed, collapsing the cell walls and aligning the cellulose nanofibers tightly. This densification results in wood that is significantly stronger than its natural form.

“This new method makes wood 12 times stronger and 10 times tougher than natural wood,” Hu said in 2018. “It could rival steel or even titanium alloys in strength and durability. It’s comparable to carbon fiber, but much more affordable.”

To test Superwood’s strength, the team fired projectiles at samples. While the bullets easily passed through natural wood, the Superwood was able to stop them partway, demonstrating its impressive durability.

To test Superwood’s strength, the team fired projectiles at samples. While the bullets easily passed through natural wood, the Superwood was able to stop them partway, demonstrating its impressive durability.

The researchers also noted that this process works with many types of wood and can be scaled up to treat large quantities at once. Early in the production, the wood remains flexible enough to be bent and molded into various shapes.

This new material could transform industries by offering a cheaper, lighter, and more sustainable alternative to steel and titanium alloys. It could even enable fast-growing, softer woods to rival traditionally sturdier—but slower-growing—species.

“This kind of wood could be used in cars, airplanes, buildings—anywhere steel is currently used,” Hu explained. “Softwoods like pine or balsa, which grow quickly and are more eco-friendly, could replace slower-growing hardwoods like teak in furniture and construction.”

What is Superwood?

Superwood is a revolutionary new material made from modified timber. It’s engineered to be 50% stronger than steel, yet lighter and more sustainable. Created through an innovative process, it promises to change the way we think about wood and its applications.

How is Superwood Made?

Scientists developed a two-step process where wood is first boiled in a chemical solution to remove certain components, then hot-pressed to align and densify the cellulose fibers. This transforms ordinary wood into a super-strong, durable material that can rival metals like steel and titanium.

Why is Superwood Important?

Besides its incredible strength, Superwood is resistant to fire, weather, and pests. It’s also renewable and more environmentally friendly than metals. This means it could become a cheaper, lighter, and greener alternative in construction, manufacturing, and transportation industries.

What Can Superwood Be Used For?

Initially, Superwood will be used for building facades, but the goal is to expand into structural applications. It has the potential to replace steel and concrete in cars, airplanes, furniture, and buildings — making these products lighter and more sustainable.

When and Where Will Superwood Be Available?

Maryland-based startup Invent Wood has raised $15 million to build a factory and plans to start shipping Superwood this Northern Hemisphere summer. The technology can be scaled quickly, and many types of wood can be used, offering a bright future for eco-friendly, high-performance wood products.

Source:SciTECHDaily

Cite this article:

Priyadharshini S (2025), Superwood” — 50% Stronger Than Steel — Arriving This Year, AnaTechMaz, pp. 216