Crystal Clear AI: Revolutionizing the Future of Electronics Manufacturing

A team of Japanese researchers, led by scientists from Nagoya University, has developed an artificial intelligence (AI) model capable of swiftly predicting crystal orientations in industrial materials. This breakthrough is expected to facilitate more efficient utilization of polycrystalline components in various technologies. The researchers achieved this by training the AI model using optical photographs of polycrystalline materials, and their findings were published in the journal APL Machine Learning.

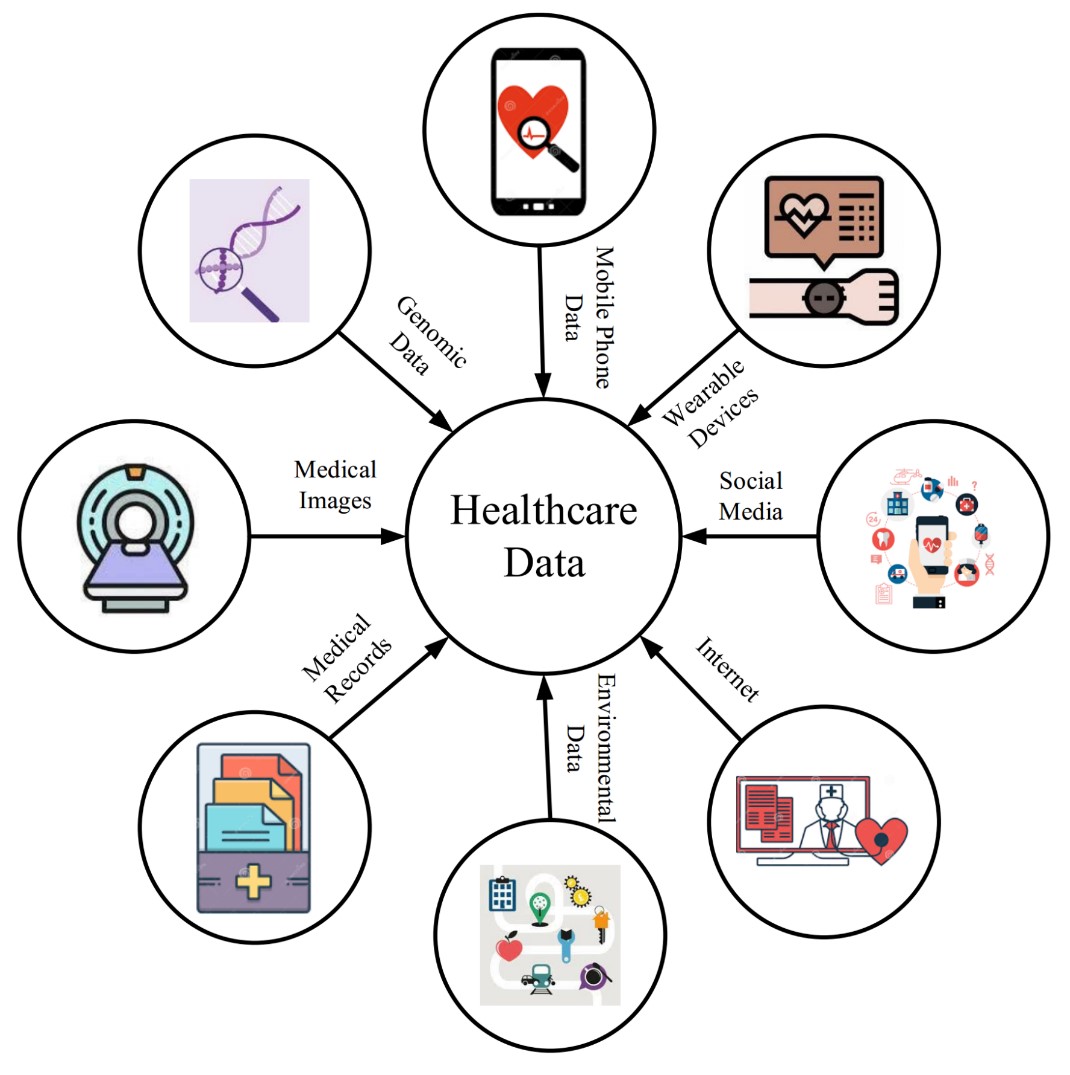

Figure 1. Crystal Clear AI: Revolutionizing the Future of Electronics Manufacturing

Figure 1 Shows Crystal Clear AI: Revolutionizing the Future of Electronics Manufacturing Crystals play a crucial role in many industrial applications, with commonly used materials such as metal alloys, ceramics, and semiconductors containing polycrystalline components. Polycrystals, composed of numerous crystals, possess a complex microstructure, and their properties vary based on the orientation of crystal grains. This prediction capability is particularly significant for materials like silicon crystals used in solar cells, smartphones, and computers.

Addressing challenges in the analysis of polycrystalline materials, Professor Noritaka Usami from Nagoya University highlights the need for control and measurement of grain orientation distribution to effectively use such materials in industry. Current techniques face limitations due to the expensive equipment and time required for measuring large-area samples.

In response, a team from Nagoya University, including Professor Usami and Professor Hiroaki Kudo, in collaboration with RIKEN, has introduced an innovative application of artificial intelligence (AI). Their machine learning model evaluates photographs taken by illuminating the surface of a polycrystalline silicon material from various directions. The AI successfully predicts the grain orientation distribution, offering a more efficient and cost-effective approach to analyze and utilize polycrystalline materials.

The innovative application of artificial intelligence for crystal orientation prediction proves highly efficient, significantly reducing the time required for measurement compared to conventional techniques. Professor Noritaka Usami emphasizes that the entire process, including taking optical photographs, training the machine learning model, and predicting orientation, takes approximately 1.5 hours, in contrast to the 14 hours needed with traditional methods. This approach also enables the measurement of large-area materials that were previously challenging with conventional techniques.

Usami envisions broad industrial applications for this technique, anticipating a revolutionary impact on materials development. He sees the potential for creating an orientation analysis system for polycrystalline materials, incorporating image data collection and a crystal orientation prediction model based on machine learning. Such a system could be adopted by many companies involved in working with polycrystalline materials, representing a significant advancement in the field.

Source:SciTechDaily

Cite this article:

Janani R (2023), Crystal Clear AI: Revolutionizing the Future of Electronics Manufacturing, AnatechMaz, pp.389