The Technology Of 5nm Processor

Vinotha D

October 19, 2021 | 1:00 PM Technology

The 5nm (nanometer) processor technology represents a major advancement in semiconductor manufacturing, enabling faster, more power-efficient, and densely packed chips. It’s part of a long trend in miniaturizing transistors—the building blocks of processors—allowing more to be placed on a single chip. Here's a breakdown of what makes 5nm processors technologically significant: Figure 1 shows Inside the Breakthrough Technology of 5nm Processors

Figure 1. Inside the Breakthrough Technology of 5nm Processors.

What Does "5nm" Mean?

- "5nm" refers to the process node, which is a marketing term used by semiconductor companies. It used to relate to the actual gate length of a transistor, but today it's more symbolic of each new generation of technology.

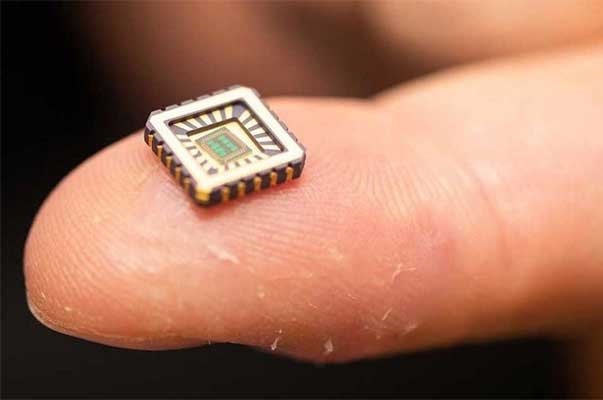

- At 5nm, billions of transistors can fit into a chip the size of a fingernail—up to 171 million transistors per mm², compared to 96 million per mm² in 7nm chips.

Key Technologies Behind 5nm Chips:

- 5nm chips use EUV lithography for precise patterning of transistors on silicon wafers.

- EUV has a wavelength of 13.5nm, enabling finer details and more accurate etching than traditional DUV (Deep Ultraviolet).

- Most 5nm chips still use FinFET (Fin Field-Effect Transistors), which are 3D transistors that reduce power leakage./li>

- Some advanced variants explore GAAFETs (Gate-All-Around FETs), which further improve control over current flow.

- Smaller transistors reduce resistance and capacitance, allowing higher frequencies (speed) and lower power consumption.

- Enables better performance for mobile devices, data centers, AI, and edge computing.

1.Extreme Ultraviolet Lithography (EUV)

2.FinFET or Nanosheet Transistors

3.Increased Density and Performance

Real-World Examples:

- Apple A14 Bionic (in iPhone 12): First commercial 5nm chip.

- Apple M1 / M1 Pro / M1 Max: Desktop-class performance in a mobile chip.

- AMD Zen 4 & NVIDIA chips: Incorporate TSMC’s 5nm process for better gaming and server performance.

- Qualcomm Snapdragon 8 Gen 1 and Samsung Exynos 2100 also use 5nm nodes.

Challenges in 5nm Technology:

- Cost: Manufacturing 5nm chips is expensive; fabs cost billions.

- Design Complexity: Needs advanced software tools and longer design cycles.

- Thermal Management: More transistors = more heat in smaller areas.

What’s Next After 5nm?

- The industry is moving to 3nm and 2nm nodes.

- New architectures like GAAFET, chiplets, and 3D stacking are being explored to sustain Moore’s Law.

Reference:

- https://semiconductor.samsung.com/news-events/news/samsung-introduces-the-industrys-first-5nm-processor-powering-the-next-generation-of-wearables/

Cite this article:

Vinotha D (2021), The Technology Of 5nm Processor, AnaTechMaz, pp. 31

Previous Post The Platform of Bitcoin Mining

Next Post AI in Cloud Computing