Pharma's Adoption Of 4.0 Is Boosted By Efficiency And Sustainability

According to Manan Shah, PhD, from Pandit Deendayal Energy University in Gujarat, India, the biopharmaceutical industry has been slower to embrace digitalization compared to other sectors. However, industry 4.0 concepts, which involve the use of interconnected and intelligent technologies in manufacturing, are beginning to gain traction in the drug industry. The desire for enhanced efficiency and sustainable production is driving this shift towards adopting industry 4.0 ideas. While industries like automotive have already experienced the transformative impact of industry 4.0, the biopharmaceutical sector is now recognizing the potential benefits of digitalization.

Figure 1.Pharma's Adoption Of 4.0 Is Boosted By Efficiency And Sustainability

Figure 1 shows According to Manan Shah, PhD, the adoption of Industry 4.0 technologies in biopharmaceutical manufacturing is still in its early stages compared to other industries, primarily due to the rigorous scrutiny involved in drug production. However, the potential advantages of data-driven and digitally enabled manufacturing, particularly in terms of efficiency and environmental sustainability, are becoming increasingly apparent. As a result, the biopharmaceutical industry is beginning to recognize the value of Industry 4.0 technologies and is gradually incorporating them into their manufacturing processes.

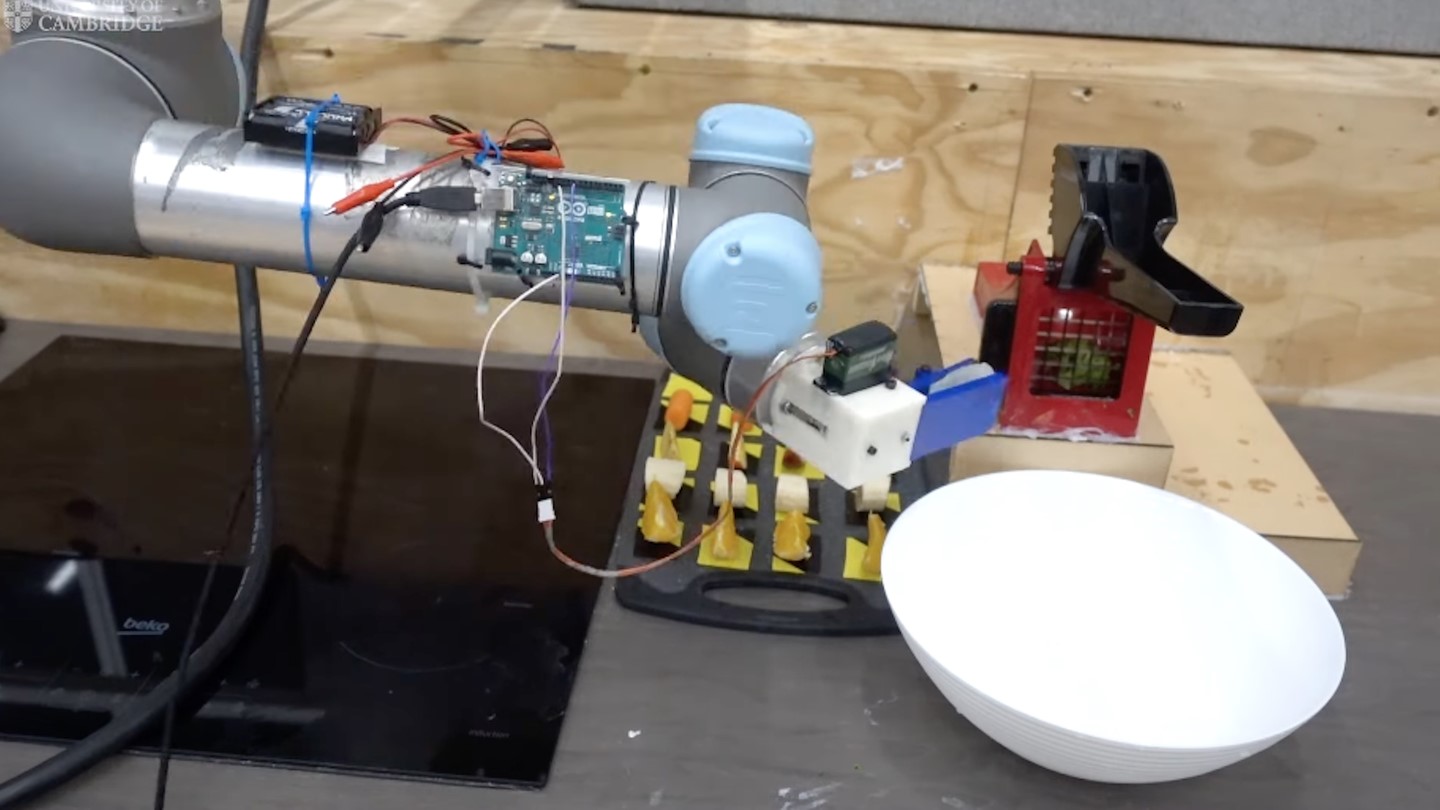

Manan Shah's view on the adoption of Industry 4.0 technologies in the biopharmaceutical industry is supported by a recent analysis published in Environmental Science and Pollution Research. The study examined the utilization of digital technologies such as artificial intelligence (AI), robotics, and the internet of things (IoT) in drug manufacturing. It provides insights into how pharmaceutical companies are embracing these digital tools to enhance their manufacturing processes.

According to Manan Shah, artificial intelligence and machine learning can play a crucial role in the biopharmaceutical industry by predicting equipment failures, optimizing maintenance schedules, and identifying and rectifying quality issues in real-time. These technologies can help reduce downtime, improve production efficiency, and mitigate the risk of manufacturing errors and recalls.In addition, the adoption of Industry 4.0 technologies can contribute to environmental sustainability in biopharmaceutical manufacturing. By enhancing energy efficiency, reducing waste, and minimizing water usage, these technologies can help companies reduce their environmental impact.

Overall, integrating Industry 4.0 technologies, particularly artificial intelligence, in biopharmaceutical manufacturing holds the potential for significant improvements in efficiency, sustainability, and product quality. This benefits both the companies and the patients who rely on their pharmaceutical products.The successful implementation of the industry 4.0 approach in biopharmaceutical companies depends on their level of preparation and infrastructure development. One of the major challenges for these companies will be managing and safeguarding data, as they are accustomed to traditional analog manufacturing processes.

Companies need to put patient data security first and make sure that new technology can work with legacy systems, he argues. "They must make investments in workforce training to prepare employees for new roles and responsibilities.[1]

References:

- https://www.genengnews.com/insights/efficiency-and-sustainability-boost-pharmas-embrace-of-4-0/

Cite this article:

Janani R (2023), Pharma's Adoption Of 4.0 Is Boosted By Efficiency And Sustainability, AnaTechMaz. pp.297