Micro-Epsilon Creates Advanced Laser Triangulation Sensors for The Next Generation

Micro-Epsilon, a leading precision sensor supplier, has expanded its optoNCDT range of laser triangulation displacement sensors by introducing a new high-performance sensor designed for demanding high-speed automation applications.

The new optoNCDT 5500 sensor delivers outstanding repeatability and high linearity, even on rapidly changing and poorly reflecting surfaces, including ceramics and metals. With a measuring rate of 75 kHz, exceptional resistance to ambient light, and enhanced temperature stability, it is the ideal solution for demanding high-speed automation tasks.

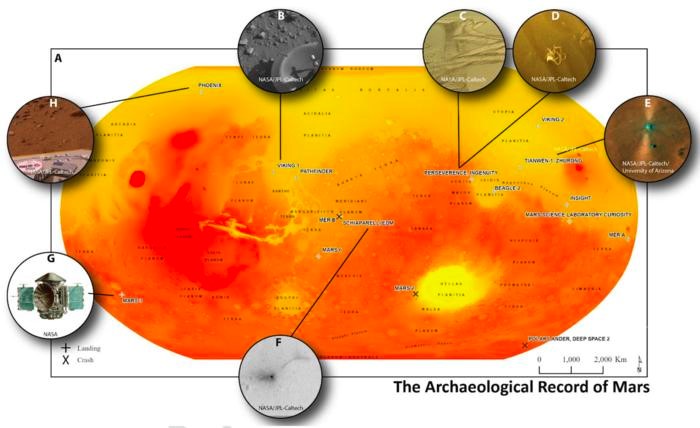

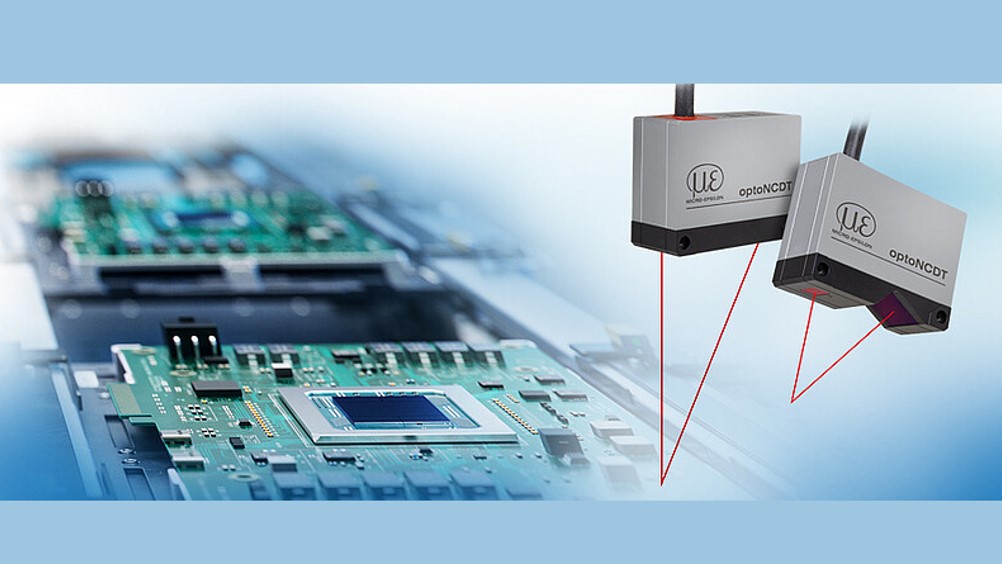

Figure 1. Micro-Epsilon Unveils Next-Generation Laser Triangulation Sensors

Designed specifically for the displacement measurement of diffusely reflective materials, the optoNCDT 5500 laser displacement sensor with an integral controller excels in challenging measurement scenarios, such as those involving rapidly changing or low-reflective surfaces [1]. Offering an adjustable measurement rate from 0.25 to 75 kHz and a maximum power consumption of just 5 W, the optoNCDT ILD5500 is also highly energy-efficient. Figure 1 shows Micro-Epsilon Unveils Next-Generation Laser Triangulation Sensors.

The optoNCDT 5500 provides exceptional precision, offering linearity from 1.5 µm and repeatability of under 0.15 µm. Its lightweight, compact, and durable aluminium die-cast housing, with an IP67 protection rating, makes it ideal for use in harsh industrial environments and allows for installation in tight spaces. The sensor is also highly resistant to shock and vibration.

Typical applications include assembly of printed circuit boards, component position testing, wear inspection of train rails, road surface testing, thickness measurement in tyre production, as well as tasks in 3D printing, automotive assembly and inspection, renewable energy, battery production, coordinate measuring machines, and precision machine building.

Thanks to advanced surface compensation and innovative software algorithms, the optoNCDT 5500 can quickly adjust exposure time, ensuring stable measurements even on surfaces with changing reflections. It is highly resistant to ambient light, functioning in environments with up to 50,000 lux of ambient light.

The sensor is available in four measuring ranges: 10, 25, 100, and 200 mm, all with both standard and extended measurement ranges [2]. The 75 kHz high-speed measurement rate is maintained without compromising range. Standard interfaces include analogue, RS422, and Ethernet, with optional interface modules supporting EtherCAT, Ethernet/IP, and PROFINET communication. Additionally, three encoder inputs are provided for direct integration and synchronization in surface mapping applications, offering excellent versatility.

The optoNCDT 5500 fits within the same space as its predecessor, the optoNCDT 2300, and shares its stand-off distances. An adapter plate is available, making the optoNCDT 5500 fully interchangeable with the optoNCDT 2300.

References:

- https://www.micro-epsilon.co.uk/newsroom/article/next-generation-laser-triangulation-sensors-offer-best-performance-in-high-speed-automation-applications/

- https://www.eurekamagazine.co.uk/content/news/micro-epsilon-develops-next-generation-laser-triangulation-sensors

Cite this article:

Janani R (2025), Micro-Epsilon Creates Advanced Laser Triangulation Sensors for The Next Generation, AnaTechMaz, pp.294