NTU Singapore Scientists Develop 3D Concrete Printing Technique for Carbon Dioxide Capture

Scientists at Nanyang Technological University (NTU) Singapore have developed a 3D concrete printing method that captures carbon, offering a promising solution to reduce the environmental impact of the construction industry.

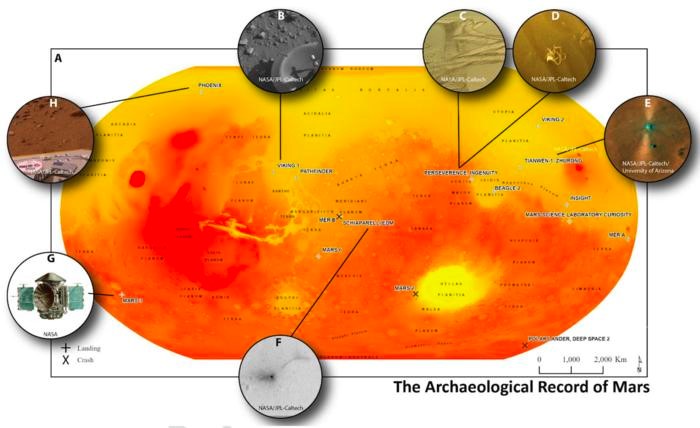

Figure 1. NTU Singapore Researchers Create 3D Concrete Printing Technique to Capture Carbon Dioxide

This innovative technique, outlined in the journal Carbon Capture Science & Technology, aims to significantly lower the carbon footprint of cement – a material responsible for 1.6 billion metric tonnes of CO2 emissions, or about 8% of global emissions. The method achieves this by using less material, shortening construction time, and reducing labor requirements. Figure 1 shows NTU Singapore Researchers Create 3D Concrete Printing Technique to Capture Carbon Dioxide

The process works by injecting steam and CO2, captured as by-products from industrial processes, into the concrete mix. This allows the CO2 to be directly incorporated and stored within the concrete structure.Results show that this method improves the mechanical properties of the concrete, enhancing its strength compared to traditional 3D printed concrete [1].

Professor Tan Ming Jen, the principal investigator of the study from NTU’s School of Mechanical and Aerospace Engineering and the Singapore Centre for 3D Printing (SC3DP), explained, “The building and construction sector contributes significantly to global greenhouse gas emissions. Our newly developed 3D concrete printing system not only improves concrete’s mechanical properties but also reduces the sector’s environmental impact. It demonstrates how CO2 from power plants or other industries can be utilized in 3D concrete printing. Since traditional cement emits a lot of carbon, our method offers a way to recycle CO2 through the printing process[2].”The research team sees this innovation as a significant step toward achieving global sustainability goals and reducing the construction industry's reliance on energy-intensive methods like reinforced concrete.

The development builds upon previous 3D printing research by Professor Tan and his team at NTU’s SC3DP, in collaboration with international partners.

Enhanced Printability, Strength, and Carbon Capture

To create the 3D concrete printing system, the team connected the printer to CO2 pumps and a steam jet. As the structure is printed, CO2 and steam are pumped into the mix, where the CO2 reacts with the concrete components, turning into a solid form that is locked into the material (sequestered). The steam aids in better CO2 absorption, enhancing the structure's properties [3].

In laboratory tests, the printed concrete showed a 50% improvement in printability, allowing for more efficient shaping and printing. The material also demonstrated better strength and durability, with a 36.8% increase in compressive strength (weight it can bear) and a 45.3% improvement in bending strength (flexibility before breaking) compared to regular 3D printed concrete.

Additionally, the method proved to be more eco-friendly, capturing and trapping 38% more CO2 than traditional 3D printing methods.

Reference:

- https://www.eurekalert.org/news-releases/1068413

- https://www.voxelmatters.com/scientists-3d-print-carbon-dioxide-capturing-concrete/

- https://www.ntu.edu.sg/news/detail/ntu-singapore-scientists-develop-3d-concrete-printing-method-that-captures-carbon-dioxide

Cite this article:

Priyadharshini S (2024), “NTU Singapore Scientists Develop 3D Concrete Printing Technique for Carbon Dioxide Capture”,AnaTechMaz, pp. 289