The Benefits & Limitations of Metal 3D Printing

Benefits of Metal 3D Printing

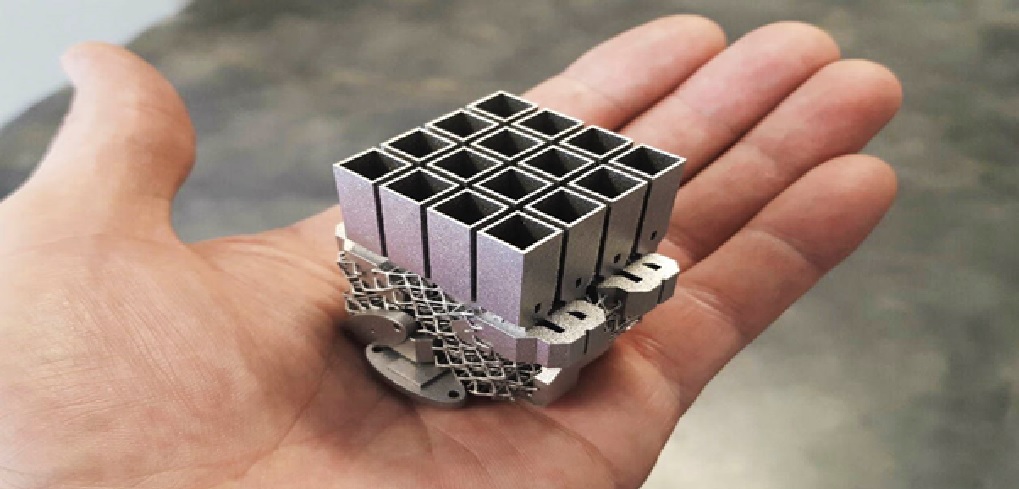

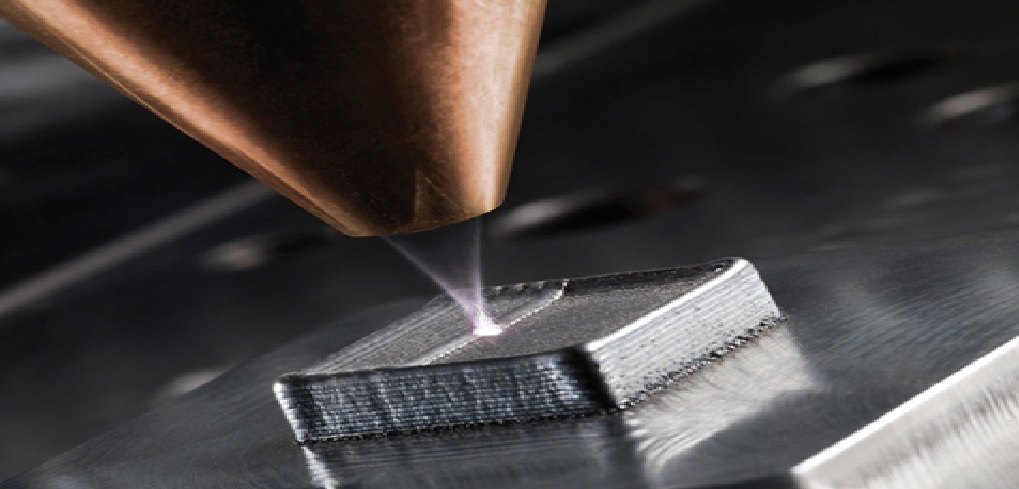

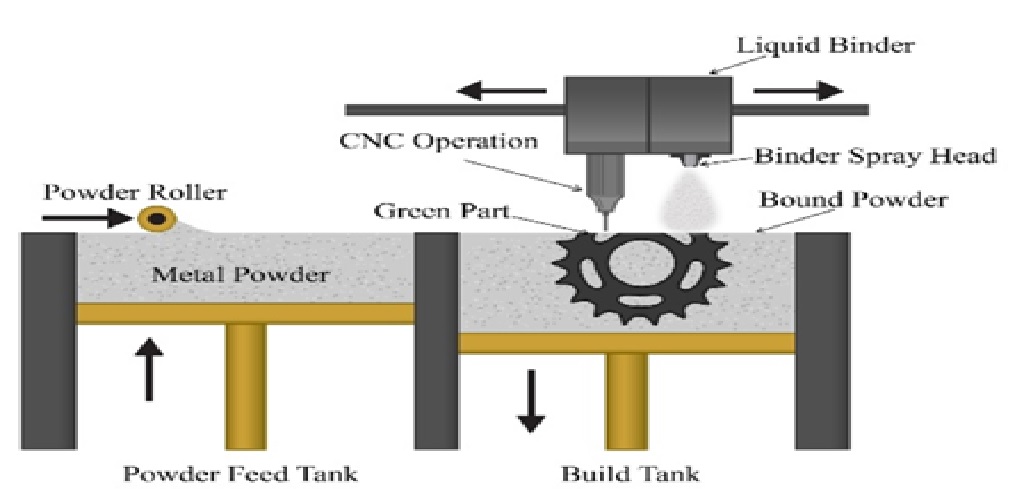

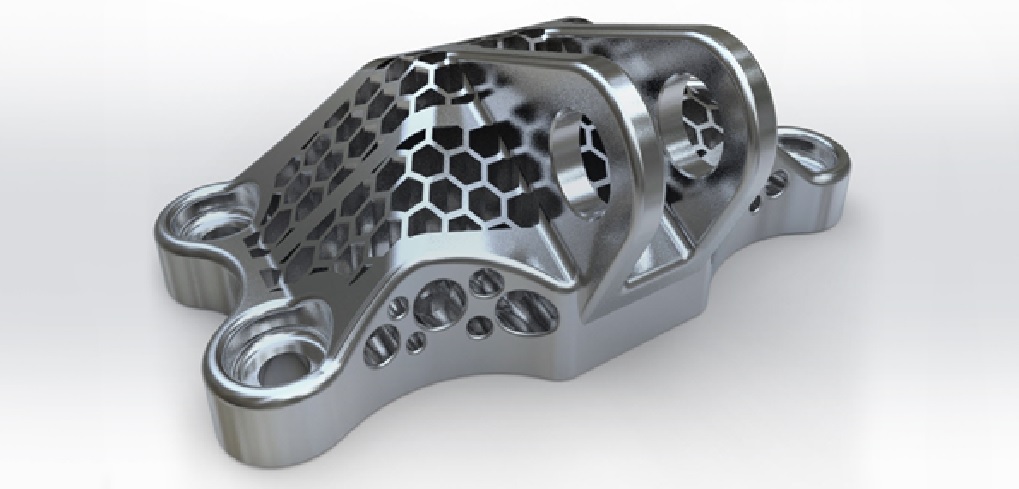

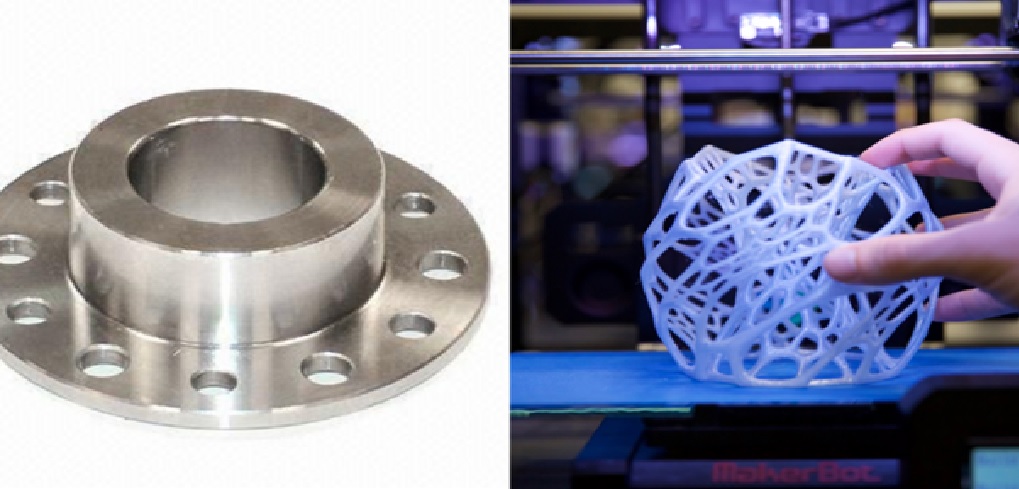

A key advantage of 3D printing with the help of a metal is that it can be utilized to develop complex and bespoke pieces. [1] These parts can have geometries which simply cannot be produced by using manufacturing processes that are normally seen as more traditional than 3D printing. On top of that, the metal products that have been made with the help of 3D printer usually have excellent physical specifications. The figure 1 shows the advantage and disadvantage of 3D metal printing.

Figure 1: The Advantage and Disadvantage of 3D Metal Printing

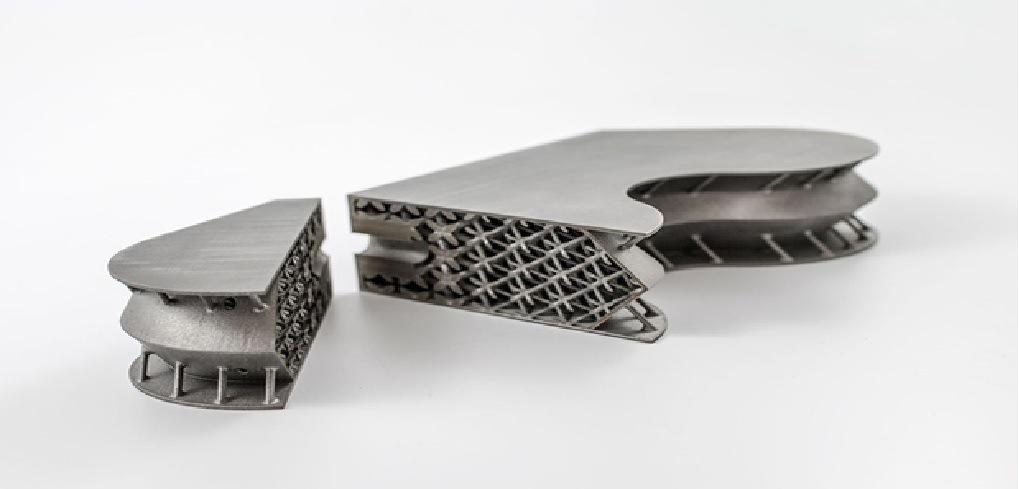

Furthermore, the available range of metal materials that can be used includes types that are usually rather hard to process. Metal superalloys are great examples of this advantage. Another benefit of the 3D printed parts that are made out of a metal is that they can be topologically optimized. This way, their performance will be maximized while their weight will be minimized.

Other advantages of 3D printing with metal include:

- The cost is cheaper in comparison with conventional methods of manufacturing. [2] Depending on the chosen technology it’s possible to create precise objects with very small details.

- 3D printing with metal almost doesn’t waste material

- Metal 3D printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce.

- Metal 3D printed parts can be topologically optimized to maximize their performance while minimizing their weight and the total number of components in an assembly. That’s why 3D printed parts are in such demand in the aerospace industry.

- Metal 3D printed parts have excellent physical properties and the available material range includes difficult to process otherwise materials, such as metal superalloys.

To sum it up, 3D printing is highly recommended for intricate parts where other types of technology are inefficient or difficult to use.

Limitations of Metal 3D Printing

3D printing is not without its faults too. First of all, it’s not as fast and affordable for regular parts in comparison with traditional methods of manufacturing. So, large-scale production is still not a viable option. Other limits of 3d printing with metal include:

- Speed of production is comparatively slow for regular objects

- Sometimes surface finishing and post-processing is needed

- Tolerance and precision are usually lower in comparison with CNC machining

- Occasionally additional heat treatment is required to reduce inner stress of the 3D printed object

- The material and manufacturing costs connected with metal 3D printing is high, [3] so these technologies are not suitable for parts that can be easily manufactured with traditional methods.

- The build size of the metal 3D printing systems is limited, as precise manufacturing conditions and process control are required.

- Already existing designs may not be suitable for metal 3D printing and may need to be altered.

As can be seen, the limits are self-evident when one compares 3D printing regular metal parts with those made using CNC machining and other manufacturing technologies. In all other cases, additive manufacturing is the real deal.

References:

- https://smallbizclub.com/run-and-grow/operations/3-benefits-and-limitations-of-metal-3d-printing/

- https://www.treatstock.com/guide/article/106-what-is-metal-3d-printing

- https://www.hubs.com/knowledge-base/introduction-metal-3d-printing/

Cite this article:

Vinotha D (2021) The Development of Metal 3D Printing Technology, AnaTechmaz, pp 5