Types of 3D Printing in Metal

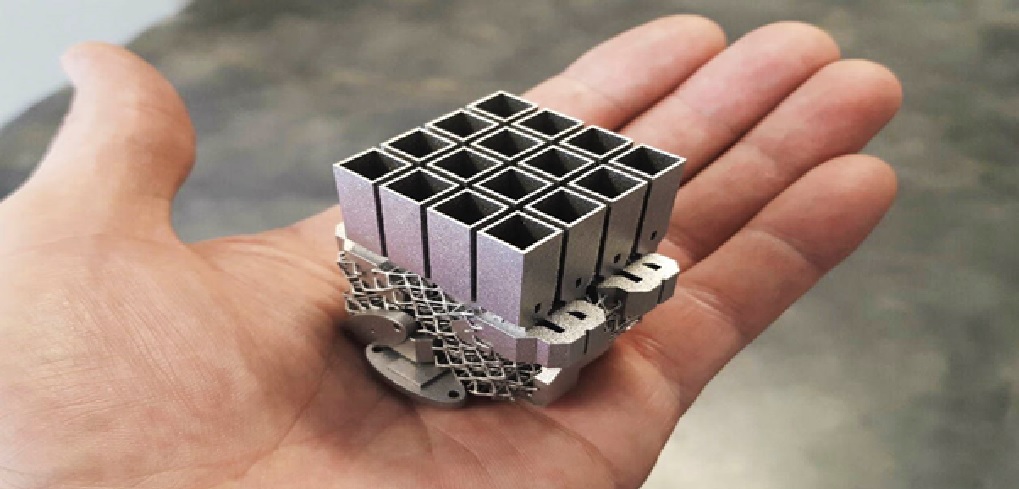

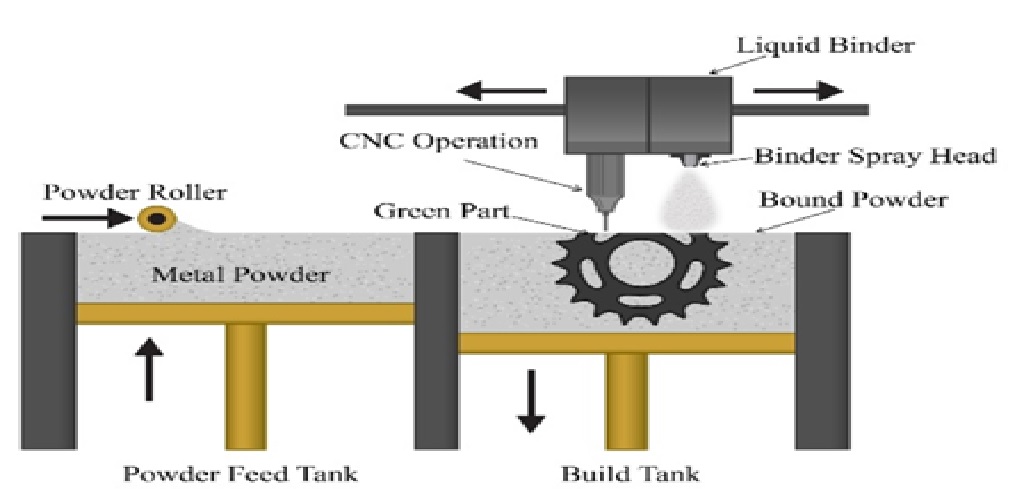

Every metal 3D printer will generally fall into one of these four categories (with a few exceptions that will be covered at the end): powder bed fusion, binder jetting, direct energy deposition, and material extrusion. The binder jetting is shown in figure 1.

Figure 1: The Metal Binder Jetting

Binder Jetting

Binder Jetting as its name implies binds powder material with a special liquid. To make the object more solid, it can be cured with hot isostatic pressing. The 3D print becomes much stronger, but at the same time, the cost also goes up. [1] Binder Jetting is usually used for manufacturing complex and large-scale prototypes. This technology is several times cheaper than DMLS/SLM/EBM. Nevertheless, accuracy and strength are not perfect, and for the best result, additional post-processing is required.

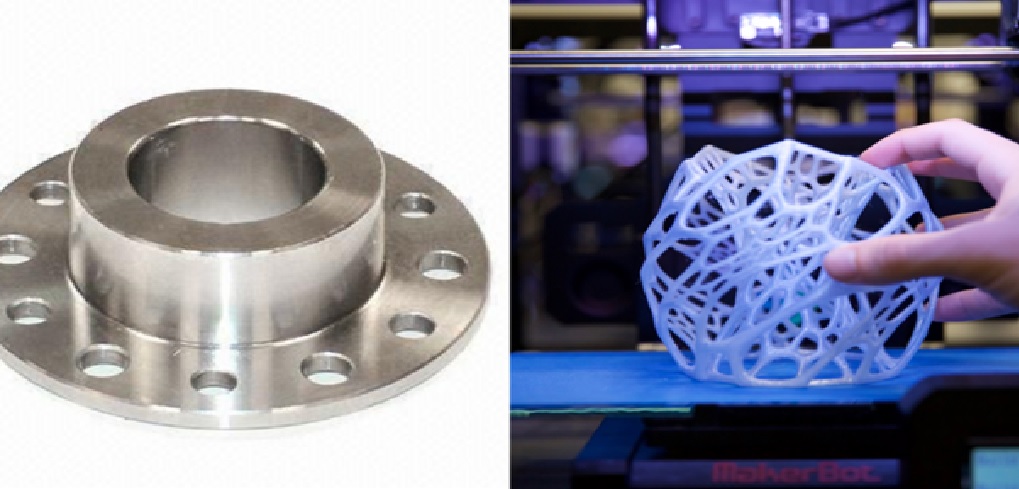

Metal Material Extrusion

This technology was specifically created to make metal 3D printing cheaper and more accessible and it’s done just that. Small and medium businesses have rapidly adopted material extrusion with metal, largely because it’s so affordable. [2] Design studios, machine shops, and small manufacturers use metal material extrusion machines to iterate designs, create jigs and fixtures, and complete small production runs. The latest development in this space is metal filaments that will work in most desktop FDM 3D printers, making metal 3D printing accessible to nearly everyone.

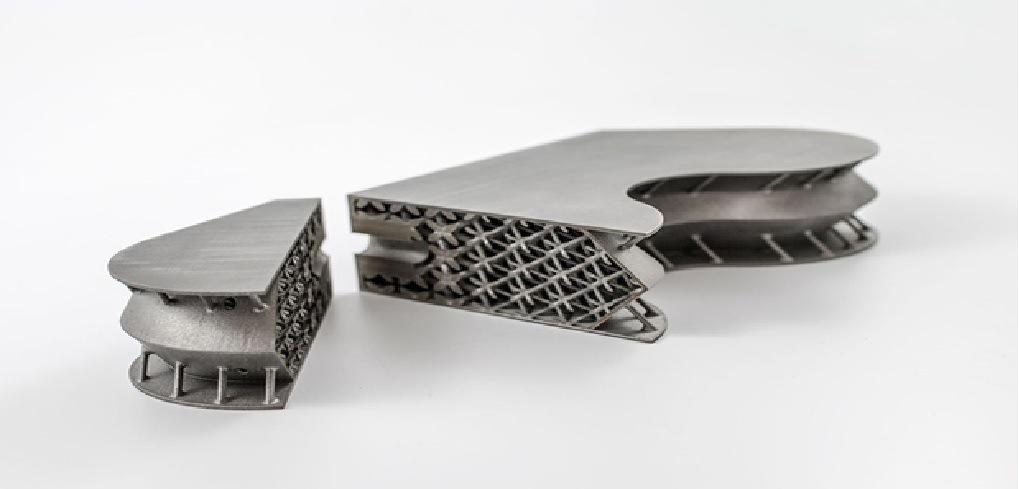

Powder Bed Fusion

Known by many names, powder bed melting is currently the most common type of metal 3D printing. These machines distribute a fine layer of powder over a build plate and selectively melt a cross section of the part into the powder layer. [3] There are two distinct types of powder bed melting techniques: Selective Laser Melting and Electron Beam Melting.

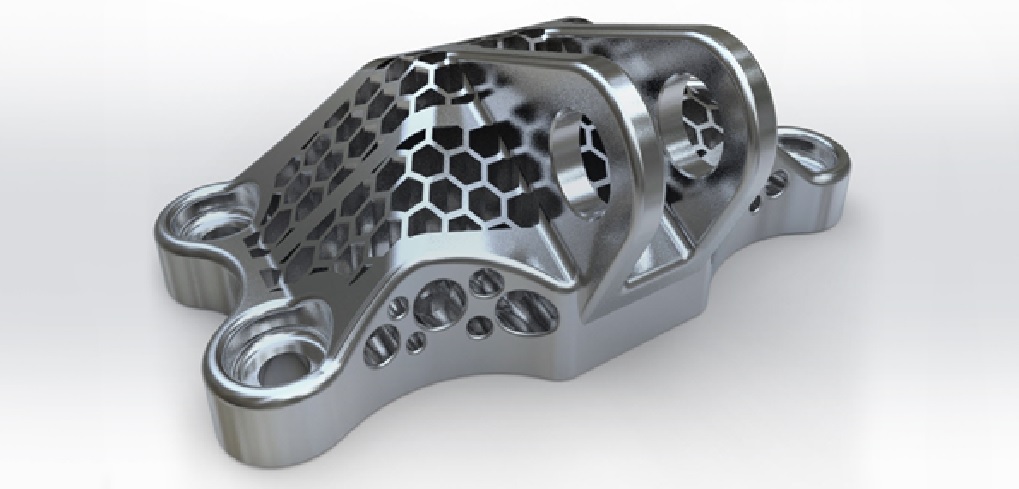

Selective Laser Melting (SLM) & Electron Beam Melting (EBM)

Both, Selective Laser Melting (SLM) & Electron Beam Melting (EBM) are similar types of powder bed fusion metal 3D printing technologies and so they are quite similar to DMLS technology with a few significant differences. SLM metal AM technology also uses a powdered metal material with lasers to fuse the adjacent particles. The difference between SLM and DMLS is in the heat. In SLM, the particles are melted rather than sintering (like in the case of DMLS).

Since metals are melted, the SLM technology is a very high-energy process. The melting can also lead to stresses inside the final product. But the SLM prints objects that are denser and stronger than DMLS. SLM technology prints with materials like stainless steel, tool steel, titanium, cobalt chrome, aluminium, nickel alloys, etc.

In the case of EBM, only the heat source changes. Instead of a laser, an electron beam is used to melt the particles to fuse them. EBM can only be used with a very limited number of materials.

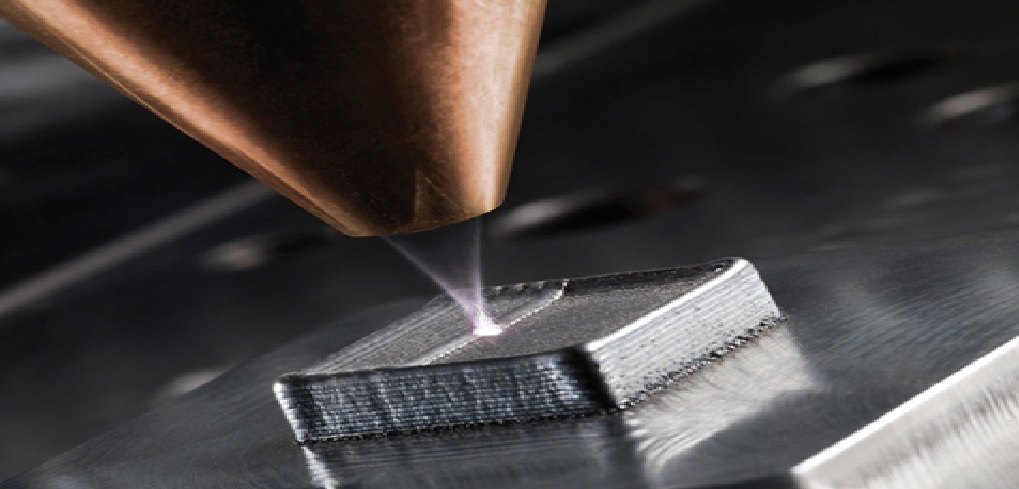

Direct Energy Deposition

Directed energy deposition (DED) is an additive manufacturing process, which laser metal deposition (LMD) technology also uses (more on this below). [4] These machines use a powder-fed system, which is similar to melting or sintering tech. DED also covers a large range of additive manufacturing sub-processes, including: Laser engineered net shaping, Directed light fabrication, Direct metal deposition and 3D laser cladding.

References:

- https://www.treatstock.com/guide/article/106-what-is-metal-3d-printing

- https://3dprinting.com/metal/types-of-metal-3d-printing/

- https://manufactur3dmag.com/a-comprehensive-list-of-metal-3d-printing-technologies/

- https://www.machines4u.com.au/mag/different-types-metal-3d-printers/

Cite this article:

Vinotha D (2021) The Development of Metal 3D Printing Technology, AnaTechmaz, pp 3