The Metal 3D Printing Working Process

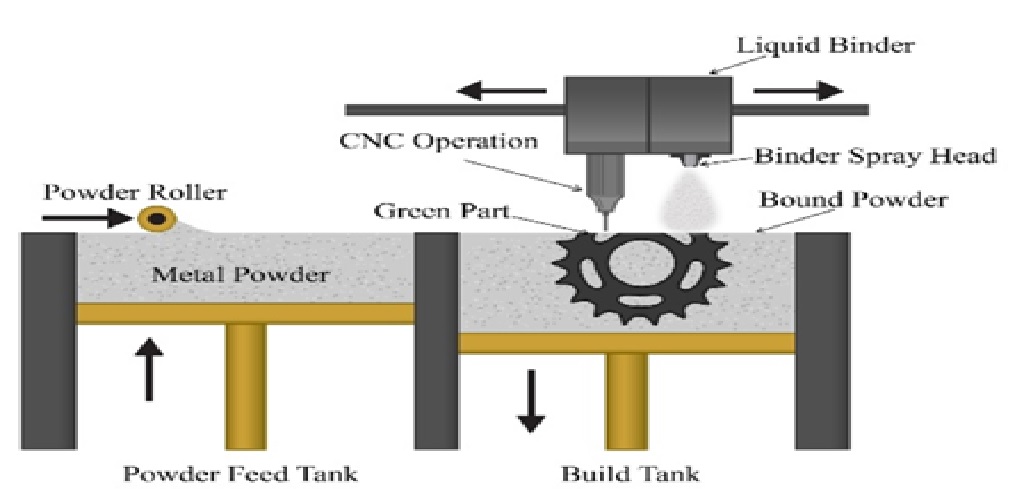

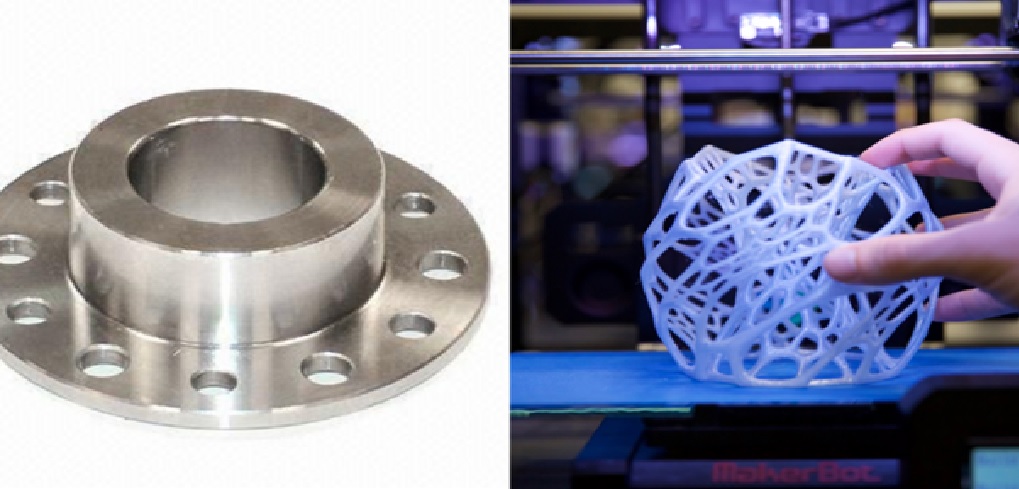

3D printing, in general, is a revolutionary technology which uses just the 3D CAD data of a component to create the physical component layer by layer. [1] Depending on the application, different materials such as thermoplastics, wax, sand and metal can be chosen as the raw material for 3d printing. The working process of metal 3D printing is shown in figure 1.

Figure 1: The Working Process of Metal 3D Printing

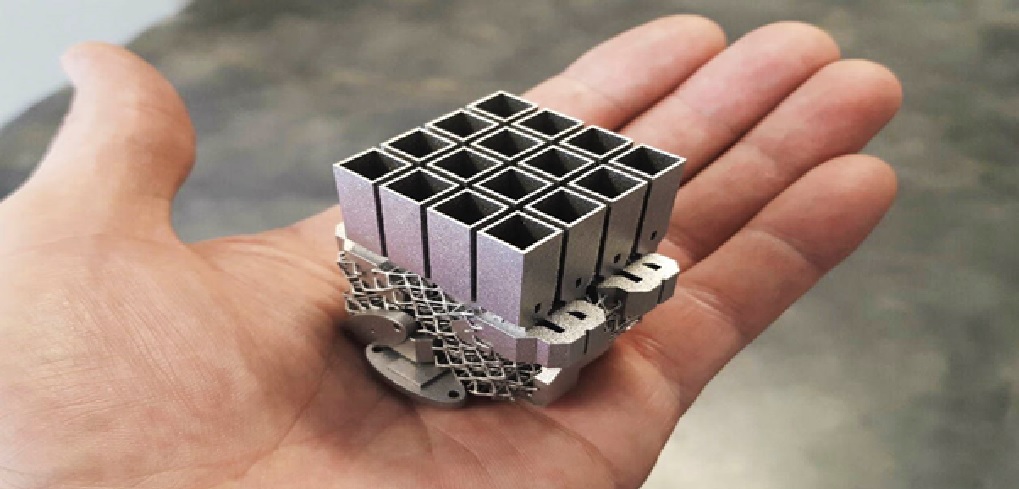

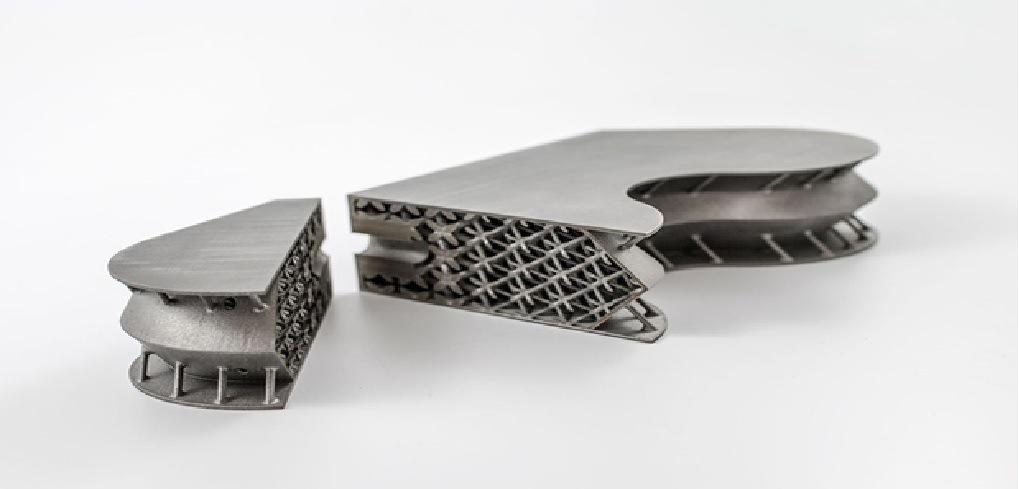

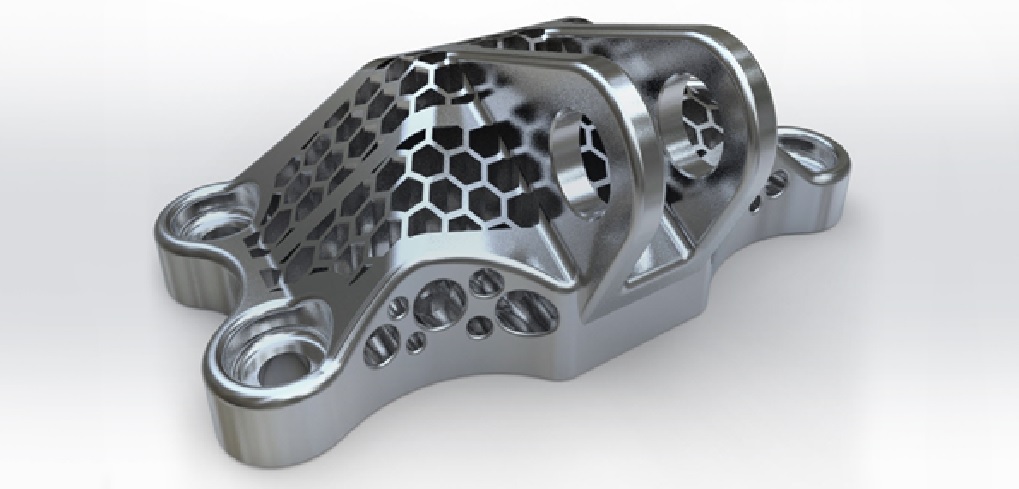

3D printing of metals is a complex process compared to other materials as it involves advanced machines and higher temperatures. Components impossible to be manufactured through other methods such as machining and casting, can now be easily manufactured through Metal 3D printing.

Although still in the nascent stage, Metal 3D printing has found a niche foothold in the manufacturing of components for the Aerospace, Automotive, Tooling and Medical industries.

The basic fabrication process for SLM and DMLS are very similar. [2] Here is how it works:

- The build chamber is first filled with inert gas (for example argon) to minimize the oxidation of the metal powder and then it is heated to the optimal build temperature.

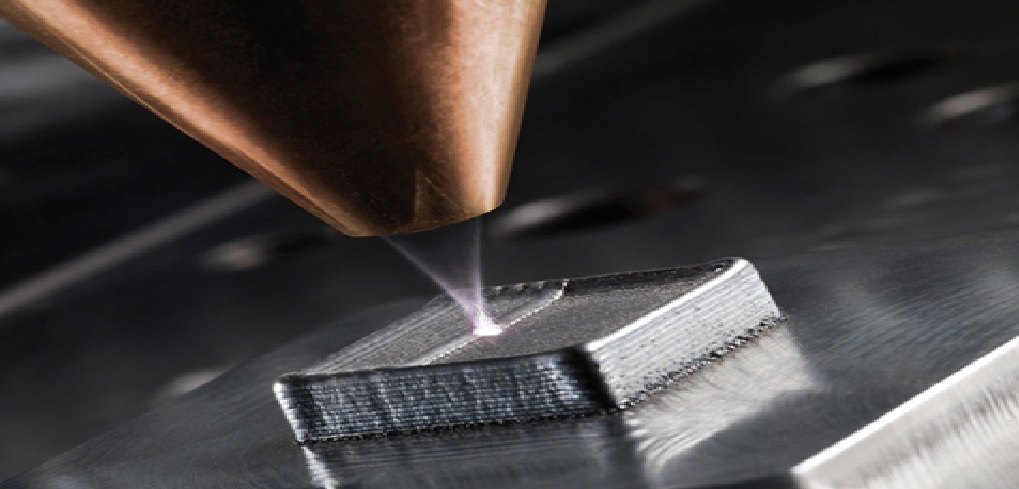

- A thin layer of metal powder is spread over the build platform and a high power laser scans the cross-section of the component, melting (or fusing) the metal particles together and creating the next layer. The entire area of the model is scanned, so the part is built fully solid.

- When the scanning process is complete, the build platform moves downwards by one layer thickness and the recoater spreads another thin layer of metal powder. The process is repeated until the whole part is complete.

When the build process is finished, the parts are fully encapsulated in the metal powder. Unlike polymer powder bed fusion process (such as SLS), the parts are attached to the build platform through support structures. Support in metal 3D printing is built using the same material as the part and is always required to mitigate the warping and distortion that may occur due to the high processing temperatures.

Metal 3D Printing is a laser-based technology that uses powdered metals. Similar to Laser Sintering, a high-powered laser selectively binds together particles on the powder bed while the machine distributes even layers of metallic powder. [3] Support structures are automatically generated and built simultaneously in the same material, and are later manually removed. Once complete, the part undergoes heat treatment.

There is a variety of metal material that is available for metal 3D systems. The most common materials used are stainless steel, aluminum, nickel, cobalt-chrome and titanium alloys. Other materials are tool steels, nichol based alloys, precious metal alloys, and copper alloys. When deciding on a material, properties such as tensile strength, hardness and elongation are important. Because there is a wide variety of material, the right material for a project can be easily factored in the specification of a product.

3D metal printing does not include any filaments. Instead, it is based on a very fine steel powder. The powder used by 3D printers can’t just be any kind of powder, since it will be used for ultra-thin printing layers. [4] The powder must be perfectly shaped in order to hold an even surface. A super-thin layer of steel powder is spread out with a roller. Then, a printer head places tiny drops of glue on the areas of the layer that are part of the design. The layer is then dried using powerful overhead heaters. The 3D printer will continue to spread out one layer of powder after another, and the printer head will systematically glue the correct spots of each layer together.

References:

- https://www.rapiddmls.com/how-does-metal-3d-printing-work/

- https://www.hubs.com/knowledge-base/introduction-metal-3d-printing/

- https://www.materialise.com/en/manufacturing/3d-printing-technology/metal-3d-printing

- https://www.manufacturingtomorrow.com/article/2019/06/the-technology-of-3d-metal-printing/13492

Cite this article:

Vinotha D (2021) The Development of Metal 3D Printing Technology, AnaTechmaz, pp 2