Multidirectional Artificial Muscle Paves the Way for Soft, Flexible Robots

MIT engineers have developed a method to grow artificial tissues that mimic the behavior and appearance of natural muscle. Human movement relies on the coordination of multiple skeletal muscle fibers, each contributing to different motions. While some muscles are aligned in a single direction, others form complex patterns, enabling versatile movement.

In recent years, scientists have explored using muscle fibers as actuators for "biohybrid" robots—machines powered by soft, artificially grown muscle. These bio-bots could move through tight spaces where traditional machines struggle. However, most artificial muscles created so far only pull in one direction, limiting the flexibility of such robots.

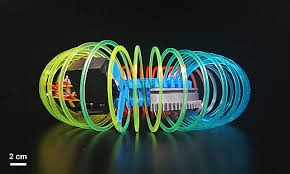

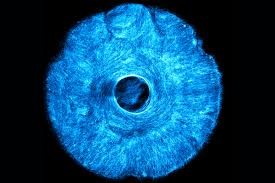

Figure 1. Multi-Directional Artificial Muscle Enables Soft Robots

MIT engineers have developed a technique to grow artificial muscle tissue that moves in multiple coordinated directions. To showcase this, they created an artificial muscle-powered structure that mimics the iris in the human eye, contracting and expanding in both concentric and radial directions. Figure 1 shows Multi-Directional Artificial Muscle Enables Soft Robots.

The team used a novel "stamping" method to fabricate the artificial iris. First, they 3D-printed a small stamp with microscopic grooves, as tiny as a single cell. They then pressed the stamp into a soft hydrogel and seeded the grooves with real muscle cells. As the cells grew along the grooves, they formed fibers, which, when stimulated, caused the muscle to contract in multiple directions, following the fibers’ alignment.

MIT engineers have developed a method to create the first skeletal muscle-powered robot that generates force in multiple directions, demonstrated with an artificial iris design. This innovation was made possible by a novel stamping technique.

The stamp, which can be printed using a tabletop 3D printer, features microscopic grooves that can be customized to grow complex muscle patterns, and potentially other biological tissues like neurons or heart cells. This method replicates the natural architecture of tissues, offering precision in fabrication.

Ritu Raman, the lead researcher, emphasized the need for such precision to replicate real tissue architecture. The team's open-access findings were published in Biomaterials Science. Co-authors include Tamara Rossy, Laura Schwendeman, Sonika Kohli, Maheera Bawa, Pavankumar Umashankar, along with collaborators from Tel Aviv University.

Training Ground

Raman’s lab at MIT focuses on developing biological materials that replicate the sensing, activity, and responsiveness of real tissues, with applications ranging from medicine to robotics. She is working on creating artificial tissue to restore function to individuals with neuromuscular injuries and exploring muscle-powered soft robotics, such as swimmers that mimic the movement of fish.

Raman has previously developed innovative methods, such as a hydrogel mat that encourages muscle cells to grow into fibers and a system that "exercises" these cells through light-induced twitching. Despite these advances, creating artificial muscle tissue that moves in multiple, predictable directions remains a challenge, particularly in replicating the multi-directional alignment seen in natural muscles like those in the iris or around the trachea.

Blueprint for Artificial Muscle

MIT engineers have developed an innovative method to grow multidirectional muscle tissue using a unique stamping technique. Inspired by Jell-O molds, the team designed a stamp with microscopic patterns that can be imprinted onto a soft hydrogel, guiding muscle cells to grow in specific directions. After coating the stamp with a protein to prevent tearing, they used it to create a muscle pattern similar to the human iris, which has both concentric and radial muscle fibers. By genetically engineering muscle cells to respond to light, the team demonstrated that the artificial muscle could contract in multiple directions, mimicking natural muscle behavior.

Although the muscle tissue was made with skeletal muscle cells, the technique is versatile and could be applied to other types of cells. The stamp can be made with high-precision printing or conventional tabletop 3D printers, offering a new way to create complex muscle structures. This advancement opens possibilities for creating soft, biologically-powered robots, which could be more energy-efficient and sustainable compared to traditional rigid actuators. The project, supported by various U.S. military and research organizations, aims to push the boundaries of biohybrid robotics and muscle-powered applications.

Source: MIT News

Cite this article:

Janani R (2025), Multidirectional Artificial Muscle Paves the Way for Soft, Flexible Robots, AnaTechMaz, pp. 149