Advanatges of Phase Change Memory – PCM

Phase change memory (PCM) is a type of non-volatile RAM that stores data by changing the state of the material used, meaning it changes back and forth between amorphous and crystalline states on a microscopic level. PCM is considered an emerging technology.

PCM is 500 to 1,000 times faster than normal flash memory. PCM technology can also offer cost-effective, high-volume and high-density nonvolatile storage on an unparalleled scale. Phase change memory is also known as perfect RAM, PCME, PRAM, PCRAM, ovonic unified memory, chalcogenide RAM and C-RAM. [1]

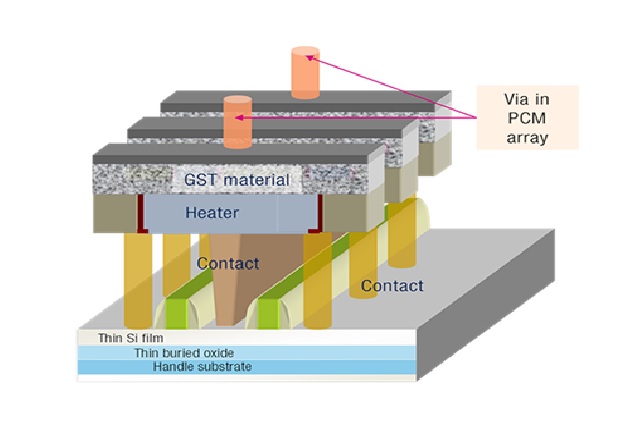

Figure 1. Advantages of Phase Change Memory – PCM

Figure 1 shows the structure of PCM material can change rapidly back and forth between amorphous and crystalline on a microscopic scale. In the amorphous or disordered phase, the material has high electrical resistance; in the crystalline or ordered phase, its resistance is reduced. This allows electrical currents to be switched on and off, representing digital high and low states. Because the physical structure is three-dimensional, the number of transistors that can exist in a chip of fixed size can be maximized, making it possible for PCM to function many times faster than conventional flash memory, while using less power. [2]

Phase-Change Memory Advantages

Write Performance / Data Retention

With single-bit alterability, PCM technology delivers significantly better write and comparable read performance than Flash-based memories that require at least a byte- or sector-erase cycle before reprogramming. This single-bit alterability simplifies software handling of data storage. ST’s implementation benefits from patented technology related to the memory cell and to the GST alloy to support high-temperature data retention, including during solder reflow, so firmware can be uploaded to ePCMs before mounting and soldering.

High Density / Low Power Roadmap

The speed/power characteristics of the ePCM macro-cell and its roadmap at smaller geometries offer a scalable solution for large embedded memories.

Robust Performance

ST’s PCM technology has been developed and tested to operate within the most stringent automotive requirements for robust high-temperature operation, radiation hardening, and data retention. ePCM achieves automotive requirements for AEC-Q100 Grade 0 with an operating temperature up to +165°C.

Flexible Back-end Process

ePCM is a back-end technology which separates the non-volatile memory-cell process module from the complex logic-transistor modules built in the Front-End. As a Back-End, metallization-based process, ePCM is technology-independent, so it can be embedded in virtually any technology node.

FD-SOI and PCM Combined

Fully Depleted Silicon on Insulator, or FD-SOI, another technology that ST pioneered, is a planar process technology that delivers the benefits of reduced silicon geometries while actually simplifying manufacturing. Combining 28nm FD-SOI and PCM enables memory array sizes that are 4-5 times larger than what Flash on bulk 40nm CMOS can achieve. [3]

References:

- https://www.techopedia.com/definition/2797/phase-change-memory-pcm

- https://whatis.techtarget.com/definition/phase-change-memory-PCM

- https://www.st.com/content/st_com/en/about/innovation---technology/PCM.html

Cite this article:

Thanusri swetha J (2021), Advanatges of Phase Change Memory – PCM, Anatechmaz, pp. 32