Introducing a Cost-effective, High-efficiency Photonic Integrated Circuit Platform

Advancements in photonic integrated circuits (PICs), which consolidate various optical devices onto a single chip, have significantly transformed optical communications and computing systems.

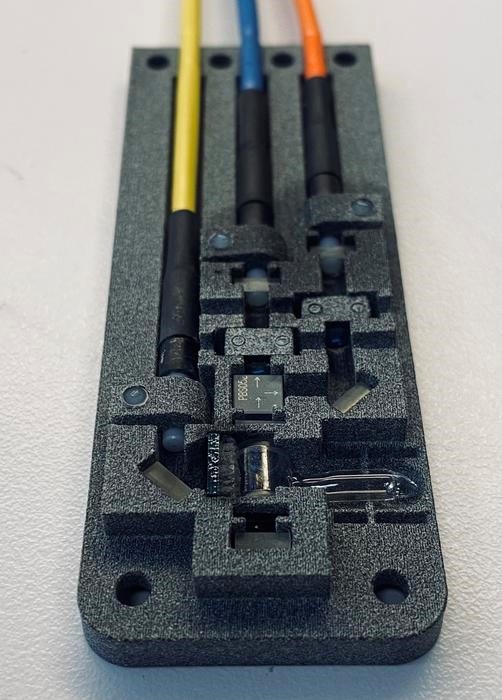

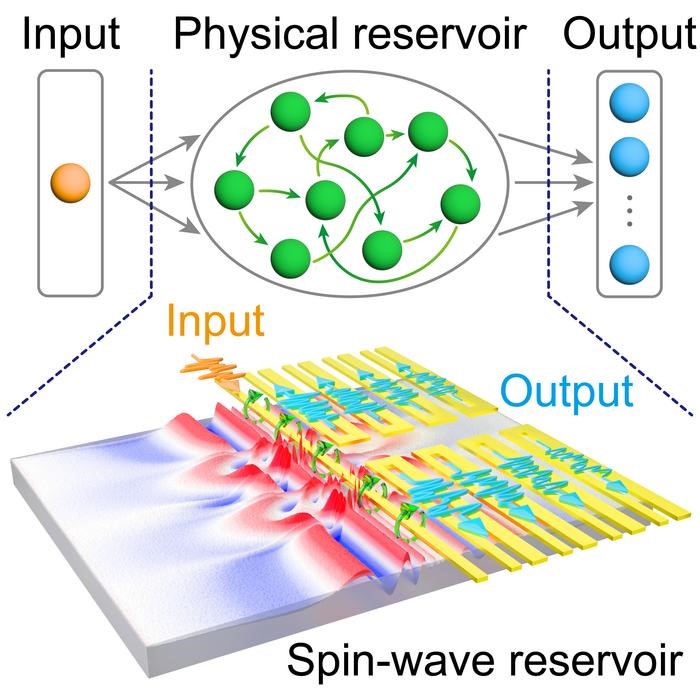

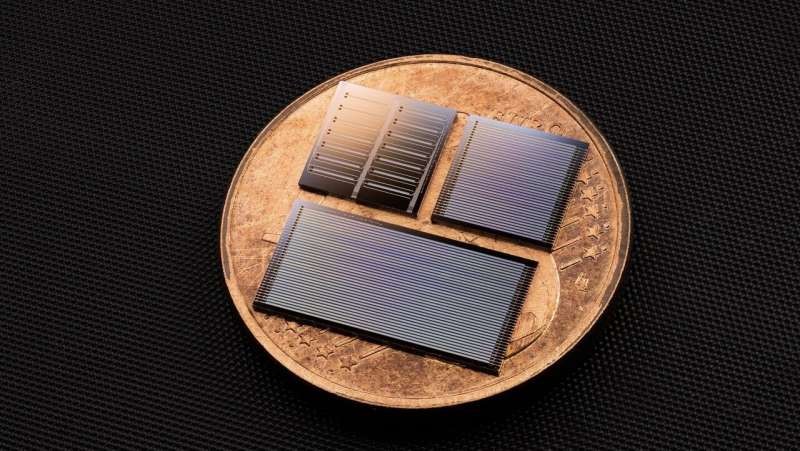

Figure 1. Lithium Tantalate Photonic Integrated Circuits. (Credit: Tobias Kippenberg (EPFL))

Figure 1 shows the lithium tantalate photonic integrated circuits. For many years, silicon-based PICs have been dominant due to their cost-effectiveness and integration with existing semiconductor manufacturing processes, despite limitations in their electro-optical modulation bandwidth. These silicon-on-insulator optical transceiver chips have facilitated data traffic through numerous glass fibers in modern data centers.

Recently, there has been a rise in the use of the lithium niobate-on-insulator wafer platform for photonic integrated electro-optical modulators. This is attributed to its strong Pockels coefficient, crucial for high-speed optical modulation. However, the adoption of lithium niobate has been hindered by its high costs and complex production requirements [1].

Lithium tantalate (LiTaO3) [1], a material closely related to lithium niobate, shows promise in overcoming these challenges. It possesses similar excellent electro-optic properties but has the advantage of scalability and cost-effectiveness, as it is already extensively used in 5G radiofrequency filters by telecom industries.

Now, a team of scientists led by Professor Tobias J. Kippenberg at EPFL and Professor Xin Ou at the Shanghai Institute of Microsystem and Information Technology (SIMIT) has introduced a new PIC platform based on lithium tantalate. This platform leverages the material's inherent advantages and has the potential to make high-quality PICs more economically viable. Their breakthrough has been published in Nature.

The researchers devised a wafer-bonding technique for lithium tantalate that is compatible with silicon-on-insulator production processes [2]. They coated the thin-film lithium tantalate wafer with diamond-like carbon and proceeded to etch optical waveguides, modulators, and ultra-high quality factor microresonators.

This etching process involved a combination of deep ultraviolet (DUV) photolithography and dry-etching techniques, originally developed for lithium niobate and then adapted for the harder and more inert lithium tantalate. The optimization of etch parameters minimized optical losses, crucial for achieving high performance in photonic circuits.

Using this approach, the team successfully fabricated high-efficiency lithium tantalate PICs with an optical loss rate of only 5.6 dB/m at the telecom wavelength. Notably, the electro-optic Mach-Zehnder modulator (MZM) achieved a half-wave voltage-length product of 1.9 V cm and an electro-optical bandwidth of up to 40 GHz.

"We not only maintained highly efficient electro-optical performance but also generated soliton microcombs on this platform," says Chengli Wang, the study’s first author. "These soliton microcombs, with their numerous coherent frequencies and combined electro-optic modulation capabilities, are particularly suitable for applications like parallel coherent LiDAR and photonic computing."

The reduced birefringence of the lithium tantalate PIC enables dense circuit configurations and ensures broad operational capabilities across all telecommunication bands. This work lays the groundwork for scalable, cost-effective manufacturing of advanced electro-optical PICs.

Source: EPFL

References:

- https://techxplore.com/news/2024-05-high-efficiency-photonic-circuit.html

- https://interestingengineering.com/innovation/lithium-tantalate-pics

Cite this article:

Hana M (2024), Introducing a Cost-effective, High-efficiency Photonic Integrated Circuit Platform, AnaTechMaz, pp. 305