Bioprinting Technology and its Applications

Bioprinting technology has emerged as a powerful tool for building tissue and organ structures in the field of tissue engineering. This technology allows precise placement of cells, biomaterials and biomolecules in spatially predefined locations within confined three-dimensional (3D) structures. Various bioprinting technologies have been developed and utilized for applications in life sciences, ranging from studying cellular mechanisms to constructing tissues and organs for implantation, including heart valve, myocardial tissue, trachea and blood vessels. In this article, we introduce the general principles and limitations of the most widely used bioprinting technologies, including jetting- and extrusion-based systems. Application-based research focused on tissue regeneration is presented, as well as the current challenges that hamper clinical utility of bioprinting technology.[1]

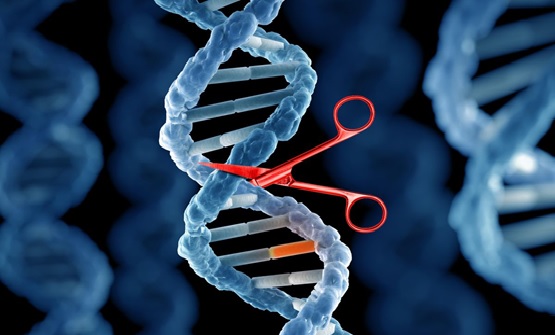

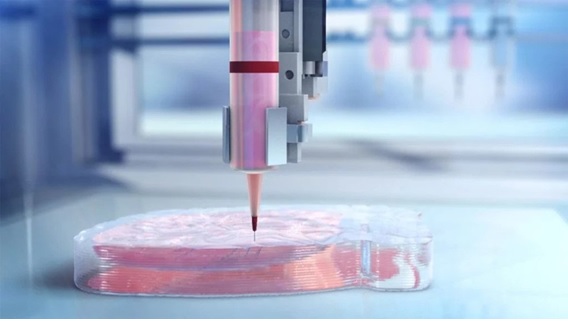

Figure 1. The Bioprinting technology and its applications

Figure 1 shows Three-dimensional (3D) bioprinting technology has emerged as a powerful biofabrication platform for tissue engineering because of its ability to engineer living cells and biomaterial-based 3D objects. Over the last few decades, droplet-based, extrusion-based, and laser-assisted bioprinters have been developed to fulfill certain requirements in terms of resolution, cell viability, cell density, etc. Simultaneously, various bio-inks based on natural–synthetic biomaterials have been developed and applied for successful tissue regeneration. To engineer more realistic artificial tissues/organs, mixtures of bio-inks with various recipes have also been developed.[2]

BIOPRINTING TECHNOLOGY

Jetting-based bioprinting

Jetting-based bioprinting is a non-contact technique in which 2D and 3D structures are generated using picolitre bio-ink droplets layered onto a substrate. This type of bioprinting can be categorized by the mechanism used to generate the bio-ink droplet: thermal method, piezoelectric actuator, laser-induced forward transfer and pneumatic pressure. The thermal method involves the use of a heat generator, which increases temperature locally within the bio-ink chamber. The local heating generates a bubble and ejects a small droplet.

Extrusion-based bioprinting

Extrusion-based bioprinting systems dispense continuous filaments of a material consisting of cells mixed with hydrogel through a micro-nozzle to fabricate 2D or 3D structures. Cell-laden hydrogel can be dispensed by using pneumatic pressure or a syringe pump, and the amount dispensed can be adjusted by controlling the pressure level or the displacement of the piston of the pump, respectively. After printing 2D patterns, hydrogels are solidified physically or chemically, and 3D structures can be fabricated by stacking 2D patterns layer by layer.

Integrated bioprinting

As is generally known, bioprinting technology relies on cell-laden hydrogels and cell aggregates to fabricate structures. However, it is difficult to fabricate 3D structures with sufficient strength, clinically applicable size and shape due to the low mechanical properties and inadequate stability of the hydrogel materials. To overcome these limitations, we recently developed a hybrid system that can concurrently print a synthetic biopolymer and cell-laden hydrogel to generate tissue constructs with high mechanical strength.

References:

- https://pubmed.ncbi.nlm.nih.gov/25061217/

- https://www.mdpi.com/2073-4360/12/12/2958

- https://academic.oup.com/ejcts/article/46/3/342/2755268

Cite this article:

Thanusri swetha J (2021), Bioprinting technology and its applications, AnaTechMaz, pp. 9