Boron Nitride NanoBarb

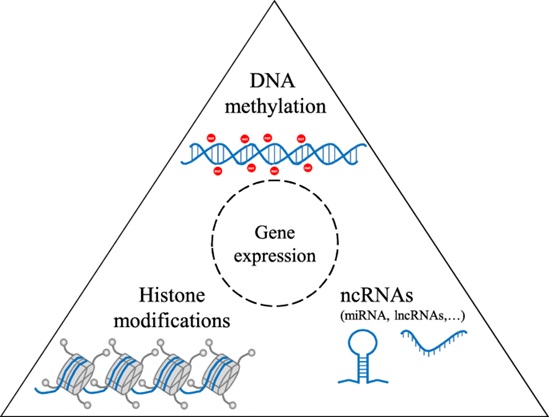

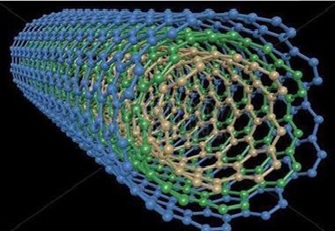

Boron Nitride NanoBarb The engineered surface of Boron Nitride Nanotubes enhances the properties of composite materials. Our innovative Boron Nitride NanoBarb was manufactured to be irregular and like "re-bar," uses mechanical [1] “barbs” to optimize the interlock with matrix materials, enhancing reinforcing properties.

The NanoBarb simplifies the handling and processing of nanomaterials by reducing the Van der Waals Attraction (minimizing contact area between particles), enabling higher loadings when mixed into other materials without agglomera.

Boron Nitride Nanotubes are a revolutionary material first explored in laboratory environments in 1995. This unique material exhibits a desirable combination of exceptional physical and chemical properties to include electrical resistivity, syperhydrophobicity and high thermal stability, thermal conductivity, strength, and stiffness. Though similar to Carbon Nanotubes, Boron Nitride Nanotubes differ in that they are electrically insulating and thermally stable to much higher temperatures broadening [2] their potential applications. Such attributes make Boron Nitride Nanotubes an ideal material for use in markets ranging from but not limited to aerospace, automotive, defense, and biomedical.

The Boron Nitride Nanotube has been identified as necessary to advance future technologies, but for the last several decades the material has remained an experimental novelty because no one could manufacture them on an industrial scale. Until BNNano figure1 shown given below.

Figure1: Boron Nitride NanoBarb

Boron nitride nanotubes used in aerospace.

Like BN fibers, boron nitride nanotubes show promise for aerospace applications where integration of boron and in particular the light isotope of boron ( 10 B) into structural materials improves both their strength [3] and their radiation-shielding properties; the improvement is due to strong neutron absorption by 10 B.

Function of boron nitride in grinding.

Its abrasive properties are tremendously relevant for tools in cutting and grinding processes. In a high pressure/high [4] temperature (HP/HT) process, the rather soft boron nitride (BN) is transformed into the cubic crystal system, where it resembles the structure of diamond.

Name of the material that forms a passivation layer of boron.

Cubic boron nitride. When in contact with oxygen at high temperatures, BN forms a passivation layer of boron oxide. Boron nitride binds well with metals, due to formation of interlayers of metal borides or nitrides. Materials with cubic boron nitride crystals are often used in the tool bits of cutting tools.

Our NanoBarbs can be used to improve thermal management of mobile electronic components, as well as make military equipment lighter, more corrosive resistant, and more blast-resistant. It is also used in particular aircraft [5] parts to help make them hypersonic.

NanoBarbs are also applicable to the water filtration and fireproofing industries.

We are not just focused on high-value applications. With our low costs, we are beginning to work in markets and applications that have traditionally been excluded from nanomaterials due to price issues.

References:

- www.bnnano.com/technology

- https://www.bnnano.com/technology

- www.sciencedirect.com/topics/chemistry/boron-nitride

- en.wikipedia.org/wiki/Boron_nitride

- https://en.wikipedia.org/wiki/Boron_nitride

Cite this article:

S. Nandhinidwaraka (2021), Boron Nitride NanoBarb, AnaTechMaz, pp. 4