A Platform of Mini Bioreactors

Solida Biotech introduce a new range of Mini Bioreactors for scale down and screening studies in fermentation and cell cultivation. Different configurations and set-up on small volumes are available to reduce materials and consumables costs to improve development results at a lower scale. Mini Bioreactors are used to generate more data saving time and money. Our systems are engineered easy to use and upgradable at any time. [1] Controller functionalities and architecture is the same from mini bioreactor to pilot scale to offer a better uniformity, simplicity and self-confidence use to our customers.

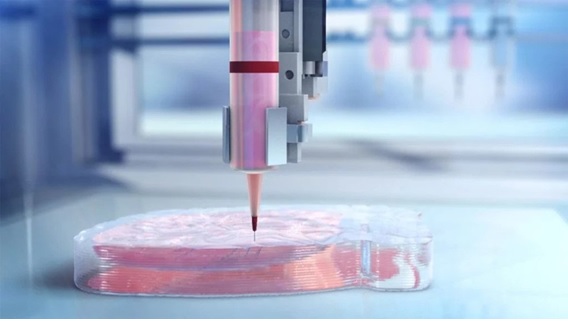

An apparatus for growing organisms (yeast, bacteria, or animal cells) under controlled conditions. Used in industrial processes to produce pharmaceuticals, vaccines, or antibodies. Also used to convert raw materials into useful by products such as in the bioconversion of corn into ethanol as shown in figure 1.

More about bioreactors:

- They are systems or devices that supports a biologically active environment.

- They are vessels in which a chemical process is carried out which involves organisms or biochemically active substances derived from such organisms.

- They can be either aerobic or anaerobic.

- They are commonly cylindrical, ranging in size from liters to cubic meters, [2] and are often made of stainless steel.

- They supply a homogeneous (same throughout) environment by constantly stirring the contents.

- They give the cells a controlled environment by ensuring the same temperature, pH, and oxygen levels.

Figure 1: Mini Bioreactors

The miniBio range of bioreactors (250 mL, 500 mL and 1000 mL total volume) is a true scale down of the classic laboratory scale bioreactor. [3] The miniBio systems have the same flexibility as the laboratory scale bioreactors. This means that the miniBio systems can be customized to fit the demands of any process. The small volume reduces media costs and maximises bench space, which is normally at a premium.

Functions of mini bioreactors:

- Generate more data in less time

- Easy setup and operation

- Cultivate using less medium

- Cultivate using les bench space

- Generate scalable results

- Mimic lab scale bioreactors

- Easy data handling

MiniBio reactor specifications:

- 250 ml total volume, 50 ml.. 200 ml working volume

- 500 ml total volume, 100 ml.. 400 ml working volume

- 1000 ml total volume, 200 ml.. 800 ml working volume

Microbial and Cell culture configuration, [4] Batch, Fed-Batch, Perfusion and Continuous cultivation, Borosilicate glass vessel, Stainless steel head plate and auxiliaries, Ports for pH, DO2 sensors, septum, foam and level sensor, overlay, chemostat, Thermowell for temperature sensor, Sparger aeration (L -sparger or porous sparger), multiple liquid inlets, sample pipe , Exhaust condenser (evaporation < 3% per day at 37°C @ 2vvm and 2000rpm), lipsealed stirrer with height adjustable impellers.

References:

- https://solidabiotech.com/product/mini-bioreactors/

- https://www.engr.colostate.edu/CBE101/topics/bioreactors.html

- https://www.applikon-biotechnology.com/en/products/cultivation-systems/mini-bioreactors/

- https://www.bioprocessonline.com/doc/mini-bioreactors-real-small-real-0001

Cite this article:

Vinotha D (2021), A Platform of Mini Bioreactors, AnaTechMaz, pp. 6