4D printing and Tissue Engineering

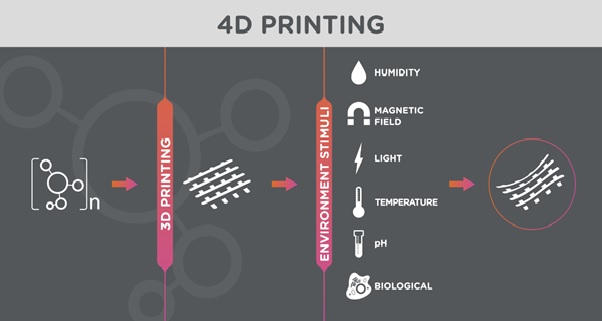

The idea of 4D printing is gaining popularity in the creation of self-healing substances for tissue engineering and manufacturing applications, but it has seen limited use in agriculture and farming applications. 4D materials when exposed to certain environments change their shape but recently available materials are of low compatibility with cells. However, the research team – led by Eben Alsberg, created new 4D materials based on gelatin-like hydrogels that alternate shape in reaction to water and are cell-compatible and recyclable, making them ideal choices for enhanced tissue engineering. The hydrogels may also maintain very high cell densities, allowing for a dense seeding of cells. In addition, they also discovered that the system can be calibrated to control the time and degree of the shape alteration. The researchers were able to implant bone marrow stem cells at a very high density in the hydrogel without destroying them, which is a huge advancement in bioengineering. Furthermore, this hydrogel’s 4D bioprinting was also used to create novel configurations for more complicated 4D constructions.[1]

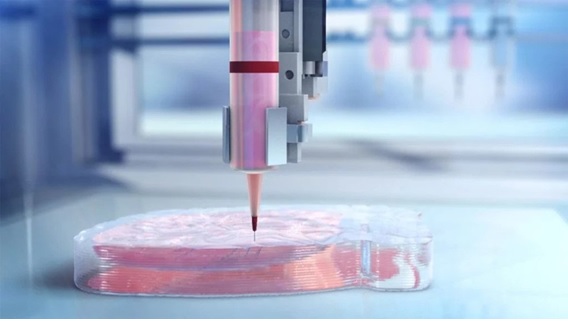

Figure 1. The 4D Printing and Tissue Engineering

Figure 1 shows Four-dimensional (4D) printing arises as a new technology that implements dynamic improvements in printed structures using smart materials (stimuli-responsive materials) and/or cells. These dynamic scaffolds enable engineered tissues to undergo morphological changes in a pre-planned way. Stimuli-responsive polymeric hydrogels are the most promising material for 4D bio-fabrication because they produce a biocompatible and bioresorbable 3D shape environment similar to the extracellular matrix and allow deposition of cells on the scaffold surface as well as in the inside. Subsequently, this review presents different bioresorbable advanced polymers and discusses its use in 4D printing for tissue engineering applications [2]

Applications of 4D printing

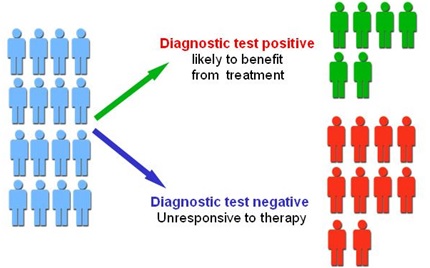

Applications of 4D printing in bone tissue engineering. (A) Injectable thermosensitive hydrogels for 4D bone tissue regeneration: the hydrogel could be injected into the irregular defect area and transform to gel state under body temperature. (B) 4D printing of bone tissue based on shape-transformation mechanism: a shape memory scaffold changes its size to occupy the void space, realizing personalized bone defect repair. (C) 4D printing of bone tissue based on the establishment of biomimetic microenvironment: the 4D printed biomimetic scaffold with modified architectures can induce the functional maturation of neo-bone tissue and promote the osteogenesis of stem cells, enhancing the formation of new bone tissue.[3]

4D printing in biomedical applications

Nature's material systems during evolution have developed the ability to respond and adapt to environmental stimuli through the generation of complex structures capable of varying their functions across direction, distances and time. In recent years, this issue has been addressed with the design and precise deployment of smart materials that can undergo a programmed morphing in response to a stimulus. The term 4D printing was coined to indicate the combined use of additive manufacturing, smart materials, and careful design of appropriate geometries. In this review, we report the recent progress in the design and development of smart materials that are actuated by different stimuli and their exploitation within additive manufacturing to produce biomimetic structures with important repercussions in different but interrelated biomedical areas.[4]

References:

- https://explorebiotech.com/biotechnology-breakthroughs-2021/

- https://www.mdpi.com/2073-4360/13/4/563

- https://www.researchgate.net/figure/Applications-of-4D-printing-in-bone-tissue-engineering-A-Injectable-thermosensitive_fig5_336868153

- https://pubs.rsc.org/en/content/articlelanding/2021/tb/d1tb01335a/unauth

Cite this article:

Thanusri swetha J (2021), 4D printing and Tissue Engineering, AnaTechMaz, pp. 8