The Scale-Up Problem in Bioprocessing May Be Solved by Microbioreactors

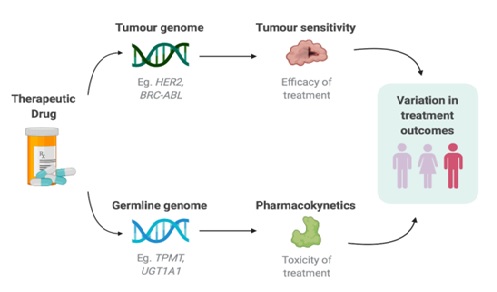

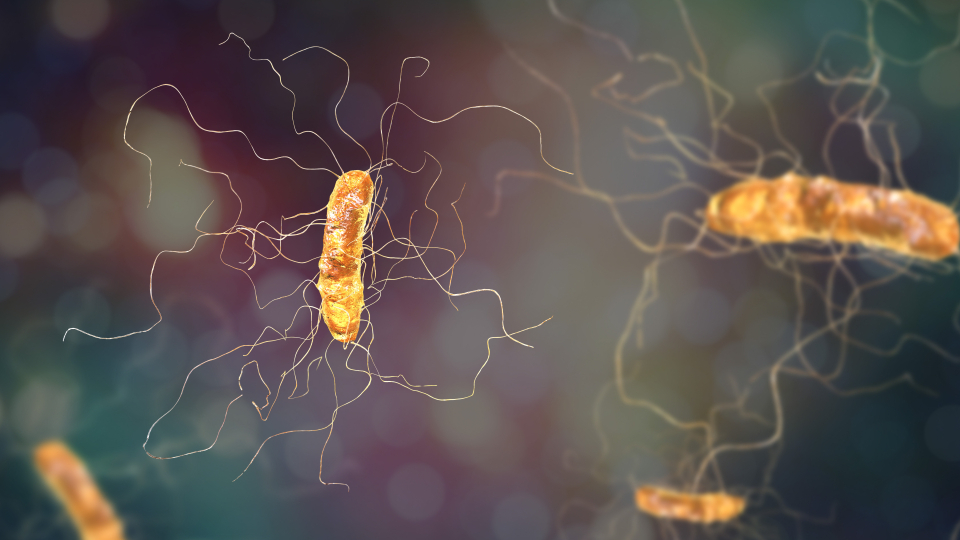

Volkert van Steijn, an associate professor of chemical engineering at Delft University of Technology, and his colleagues have conducted a review exploring the potential of microbioreactors as a solution to the challenge of mimicking industrial-scale conditions during the development of biotherapeutic-producing microorganisms. Current approaches often result in different conditions between small and large batches, impacting the success of potential products. The researchers propose that microbioreactors, which allow for precise control and monitoring of conditions, could bridge this gap and provide a more accurate representation of industrial-scale processes. This review highlights the promising role of microbioreactors in improving the development and optimization of biotherapeutic production.

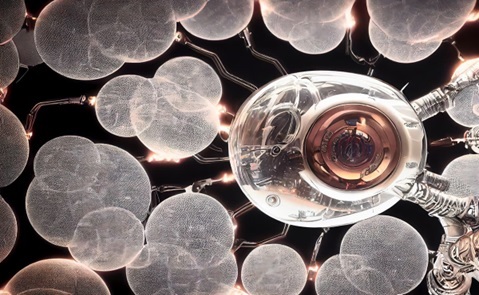

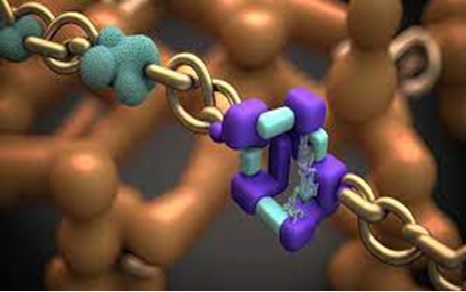

Figure .1 The Scale-Up Problem in Bioprocessing May Be Solved by Microbioreactors

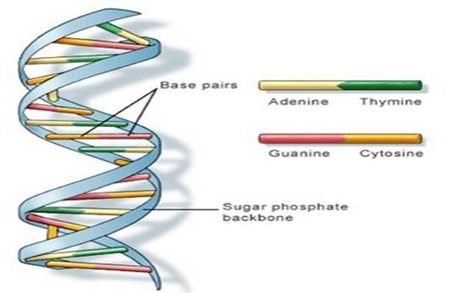

Figure 1 shows in the development of bioprocesses, it is typical to genetically modify microorganisms and analyse numerous resulting mutants to identify the most effective ones for industrial-scale use. Volkert van Steijn and his colleagues emphasize this common practice, which involves studying a large number of mutants to select the best-performing ones. By doing so, researchers aim to optimize the production of biotherapeutics and enhance the efficiency of industrial-scale processes.

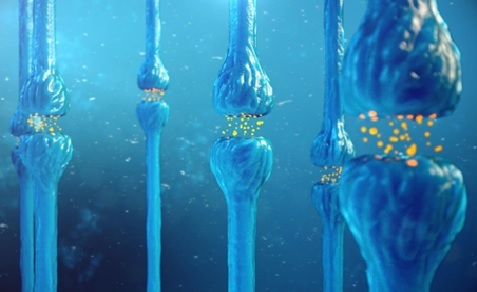

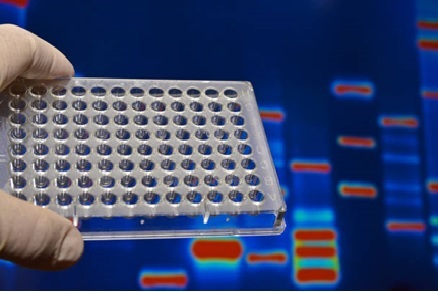

While screening mutants for bioprocess development, the current practice often involves using technology that lacks the nutrient control used at the industrial scale. Typically, mutants are screened in microtiter plates under batch conditions, where no additional nutrients are added during the experiment. Although microtiter plates enable high-throughput analysis, the small volume of the wells (ranging from 10 to 2,000 µL) limits the options for controlling the conditions. This limitation hinders the ability to mimic the nutrient conditions found in large-scale industrial processes.

Microbioreactors have the potential to provide a combination of high throughput and dynamic control over cultivation conditions, addressing the current limitations in screening mutants for bioprocess development. These microbioreactors can be created using different approaches, such as modifying microtiter plates, microfluidic chambers, or microfluidic droplet-based systems.

Modifying microtiter plates to function as microbioreactors allows for the implementation of fed-batch control of nutrients, which is commonly used in industrial processes. However, there are challenges in controlling such a small environment and in the fabrication of the modified microtiter plates. As a result, these modified plates often have a small number of wells, sometimes as few as 24, which limits the throughput of the screening process. Despite these challenges, the use of microbioreactors holds promise in achieving the desired combination of high throughput and dynamic control for more accurate bioprocess development.

Nevertheless, Steijn's team is still upbeat about microbioreactors. One possibility addressed by the researchers was the use of microbioreactors in conjunction with computer-controlled automation and optimised algorithms created from data-driven modelling to control the environment for each mutant. The researchers state in their conclusion that "Combining controlled high-throughput experimentation within microbioreactor platforms with complex feeding profiles and process control would be a promising approach to bridge the gap between screening conditions and those observed at the industrial scale."[1]

References:

- https://www.genengnews.com/topics/bioprocessing/microbioreactors-may-solve-bioprocessings-scale-up-challenge/

Cite this article:

Janani R (2023),The Scale-Up Problem in Bioprocessing May Be Solved by Microbioreactors, AnaTechMaz, pp.190