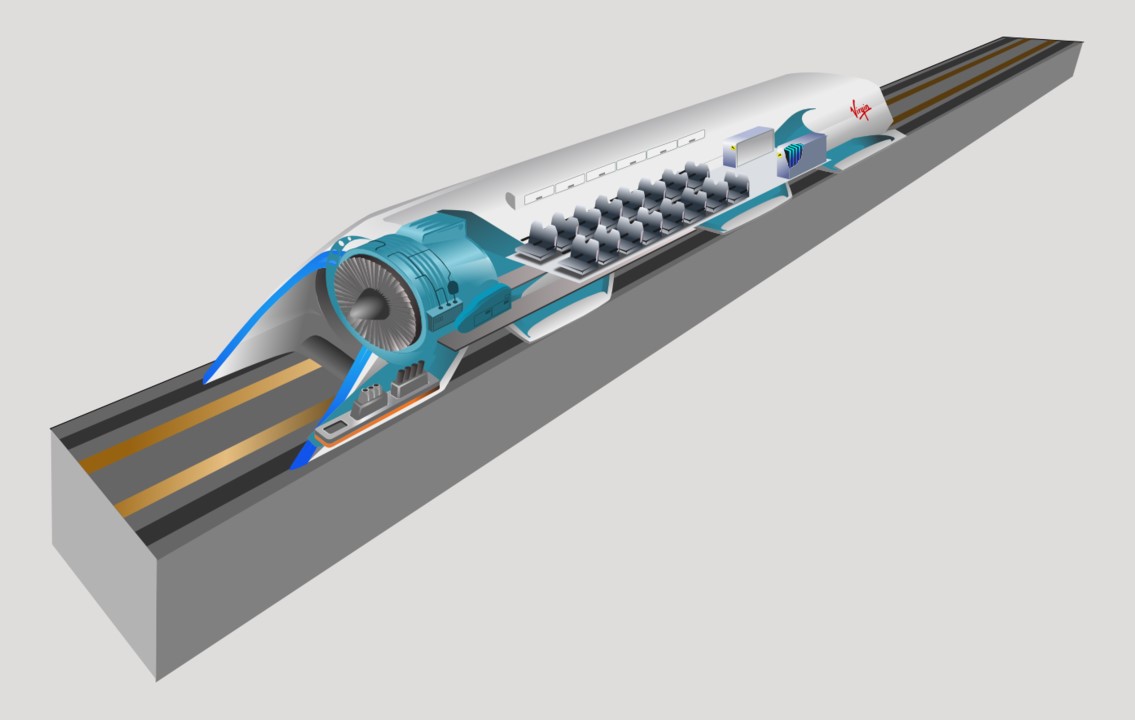

Rapid DMLS enables 3D Direct Metal Laser Sintering

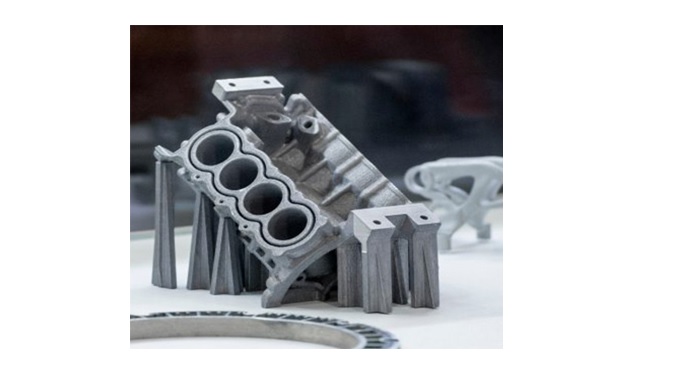

Indian startup Rapid DMLS offers metal 3D printing of functional components layer-by-layer using 3D-CAD data as the input. The startup’s technology produces parts with complex geometry using direct metal laser sintering (DMLS). This process allows printing parts with lattice structures which in turn reduces the weight while still maintaining the required strength. Weight reduction is highly useful in aerospace and manufacturing industries looking for lightweighting technologies. Additionally, the monolithic design increases the life cycle of the part. Rapid DMLS intends to assist post- 3D printing and inspection to improve the quality of parts. [1]

Figure 1. Rapid DMLS enables 3D Direct Metal Laser Sintering

Rapid DMLS enables 3D Direct Metal Laser Sintering is shown in figure 1. DMLS means laser-sintering using a metal powder, in which metal parts are produced directly in the building process.

The basic principle of the Direct Metal Laser Sintering (DMLS) Technology is to melt down thin layers (20 ÷ 60 µm) of Metal Powder with an electronically driven LASER beam (200W).[2]

Why Choose DMLS Services For 3D Printing Project?

There are a huge range of parts, components and assemblies that can be produced through metal additive manufacturing thanks to the wide range of high quality metal powders on offer. We regularly produce components using stainless steels, tool steels, copper, aluminium, nickel based alloys, titanium alloys, and high performance super-alloys such as ™Scalmalloy.

DMLS allows for highly accurate and complex structures to be created with ease. When manufacturing bespoke shapes or components rich in features, the even distribution of metal powders allows for accurate delivery on shapes as complex as honeycomb, where strength and integrity are needed at all points.

Laser sintering also provides a higher quality finish than tooled or wrought materials. The additively manufactured parts can be post machined, painted and resurfaced after development as and when required.[3]

In conclusion, Rapid Direct Metal Laser Sintering (DMLS) is an advanced 3D printing technique that enables the creation of complex metal parts with high precision and accuracy. It works by using a high-powered laser to selectively fuse metal powder into a solid part layer-by-layer, based on a digital 3D model.

References:

- https://www.startus-insights.com/innovators-guide/top-10-mobility-industry-trends-innovations-in-2021/#3d-printing

- https://www.totalmateria.com/page.aspx?ID=CheckArticle&site=kts&LN=ES&NM=488#

- https://any-shape.com/direct-metal-laser-sintering/

Cite this article:

Gokula Nandhini K (2023), Rapid DMLS enables 3D Direct Metal Laser Sintering, AnaTechMaz, pp. 121