A Materials Scientist Aims to Extract Lithium from Unconventional Sources

Chong Liu is focused on discovering new sources for a crucial component in electric car batteries. While electric vehicles are seen as a solution to reduce reliance on fossil fuels, they present a new challenge: securing enough lithium to meet the demand for their batteries (SN: 5/7/19). Materials scientist Chong Liu, based at the University of Chicago, is exploring innovative solutions. Current extraction methods are limited to sources with highly concentrated lithium ions, such as hard rocks or brine deposits. However, these sources are insufficient for future needs and carry significant environmental risks (SN: 3/15/22).

Chong Liu has identified a material that could enable lithium extraction from untapped sources. She is exploring brines from geothermal and desalination processes, fracking wastewater, and even seawater, which could eventually offer a vast lithium supply—if it can be harnessed. A significant challenge is that seawater has a sodium-to-lithium ratio of about 20,000-to-1, far less favorable than current sources with ratios in the hundreds-to-1 range.

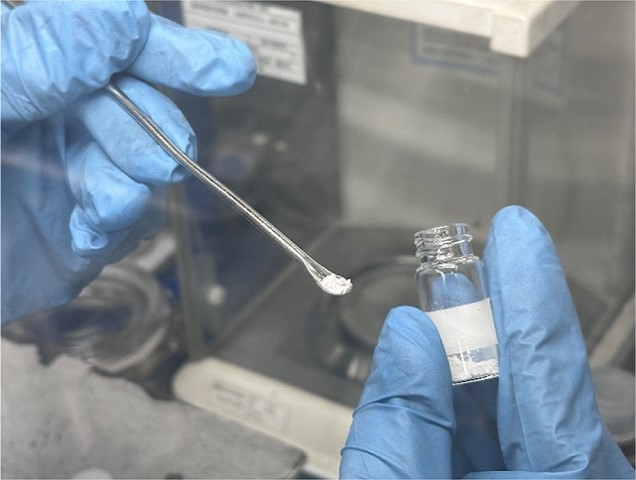

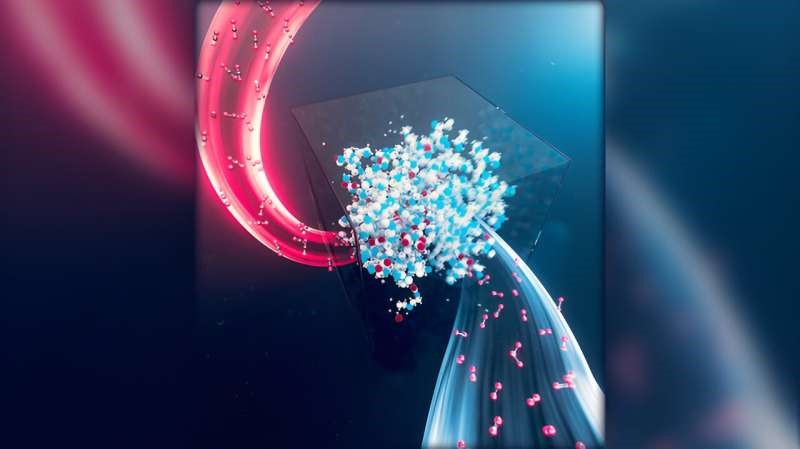

Figure 1. Chong Liu’s Team Discovers Optimal Material for Lithium Extraction through Fundamental Materials Science

Extracting lithium ions from such low-concentration solutions for commercial use will require extensive research, Liu notes. [1] However, her work has already made significant progress in improving resource extraction efficiency, according to Matthew Tirrell, a molecular engineer at the University of Chicago, who recruited Liu as an assistant professor in 2018. Liu’s research is laying the groundwork for other ion-based processes in confined, porous spaces, with potential applications from accelerating chemical reactions to treating patients with mercury or lead poisoning. Figure 1 shows Chong Liu’s Team Discovers Optimal Material for Lithium Extraction through Fundamental Materials Science.

Targeting Lithium Extraction

The method Chong Liu is developing—known as electrochemical intercalation—has only recently been applied for resource extraction. In this process, researchers submerge a material with ion-sized channels into briny water. Lithium ions move into the material’s lattice of channels, where they can be captured. However, briny water also contains sodium ions and other elements that compete for space in these channels, reducing lithium uptake.

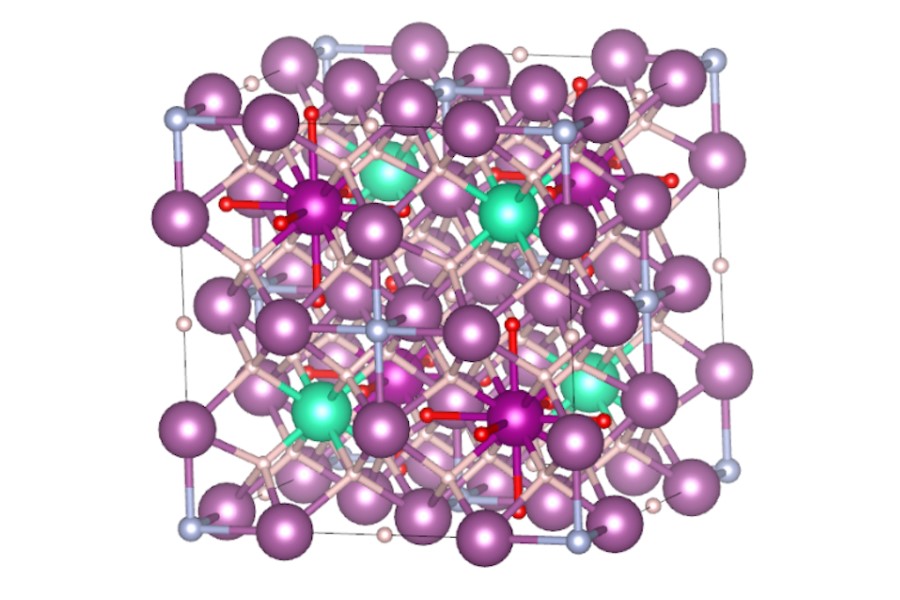

Liu began searching for an ideal material for this process in 2016 during her postdoctoral research at Stanford University. She recognized the importance of selecting the right material: “This material’s property will determine how much selectivity [for lithium] we can get, and what source water we can use,” Liu explains. The better the selectivity, the more lithium can be captured. To find the right material, she combed through scientific literature, seeking one that would be stable in water and retain its structure, even when filled with ions.

Liu eventually chose iron phosphate as the ideal material. The oxygen in iron phosphate bonds more easily with lithium than with competing sodium ions. While larger sodium ions can expand the channels, the lithium-oxygen bonds keep the channels small and more receptive to lithium. Once the material is saturated with ions, it is transferred to freshwater, where electric currents are applied to expel the ions. The researchers then add hydroxide, which combines with lithium to form solid lithium hydroxide—an essential raw material for EV batteries.

The amount of lithium that iron phosphate can currently extract is “spectacular,” says physicist Steven Chu of Stanford University, who collaborated with Liu during her postdoctoral research. Chu, a former U.S. Secretary of Energy, adds, “Having done that, you can rest on your laurels and say, ‘That’s great.’ But she’s also driven to ask, ‘Is it going to be practical?’”

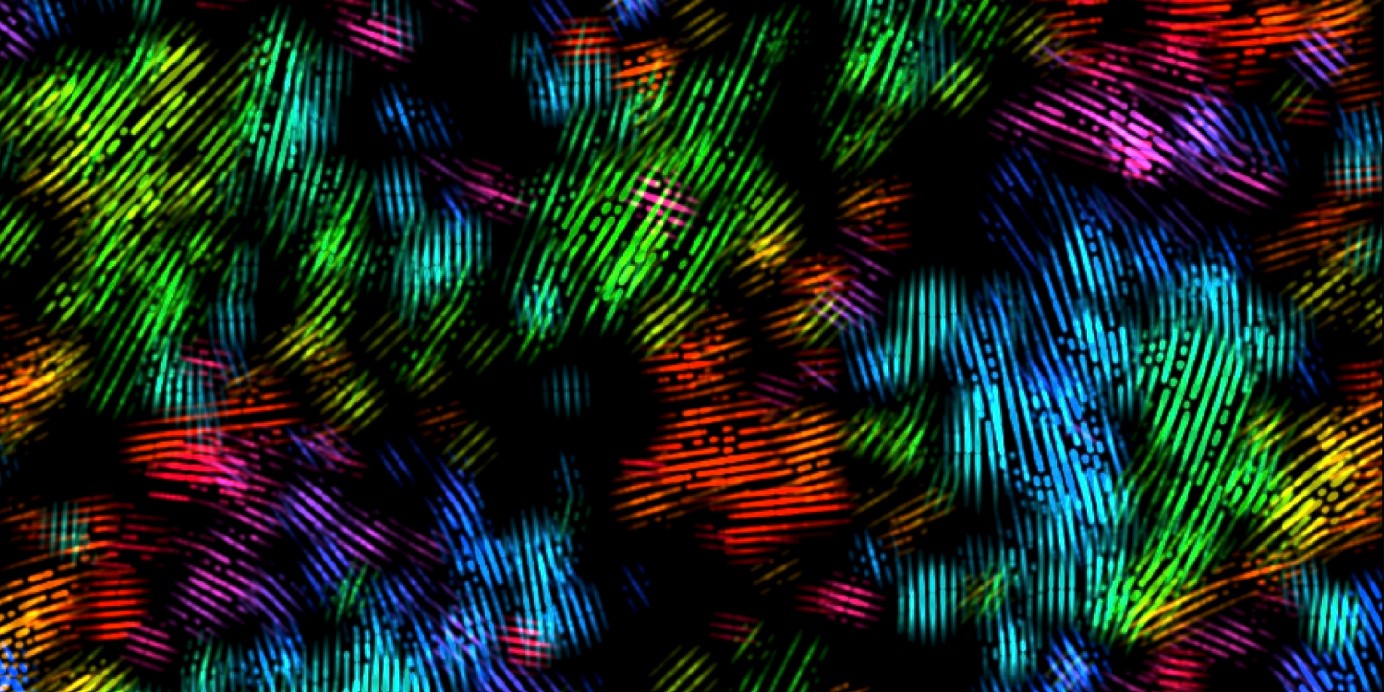

At her University of Chicago lab, Liu continues working on improving the material’s efficiency. Her team studies how lithium and sodium ions enter the material's channels, the order in which they do so, and how they interact within the material. By gaining a deeper understanding of these ion behaviors, Liu aims to enhance the material’s performance.

Digging For Insights

Liu’s team is also working on a new method to separate rare earth elements, which she says is “actually harder” than extracting lithium. [2] These 17 elements are vital for technologies like wind turbines and smartphones (SN: 1/16/23), but because they often occur together and have similar size and chemistry, separating them is a challenging task.

Beyond these extraction methods, much of the lab's research is focused on fundamental materials science. “We just accumulate more and more knowledge, so then we can start to predict things,” Liu explains. This approach led her to iron phosphate—it was the first material the team tested after extensive research.

References:

- https://world-arabia.com/articles/innovative-solutions-for-lithium-extraction-in-electric-vehicles/

- https://www.sciencenews.org/article/chong-liu-lithium-ev-batteries

Cite this article:

Janani R (2024), A Materials Scientist Aims to Extract Lithium from Unconventional Sources, AnaTechMaz, pp. 71