Nature-Inspired Designs Enhance Polymer Durability

Researchers are developing materials that emulate the patterned structures found in resilient natural organisms. Biological systems excel at crafting strong yet flexible structures; for example, sea sponges grow in layers with unique patterns that combine minerals and softer regions, achieving an optimal balance of strength and flexibility.

“Nature has a way of turning brittle materials into tough ones through intricate patterning,” said Nancy Sottos, a researcher at the Beckman Institute for Advanced Science and Technology and head of the Maybelle Leland Swanlund Endowed Chair in the Department of Materials Science and Engineering at the University of Illinois Urbana-Champaign. “Patterned materials often consist of both stiff and soft regions, enabling them to endure high strains without breaking while maintaining remarkable strength.”

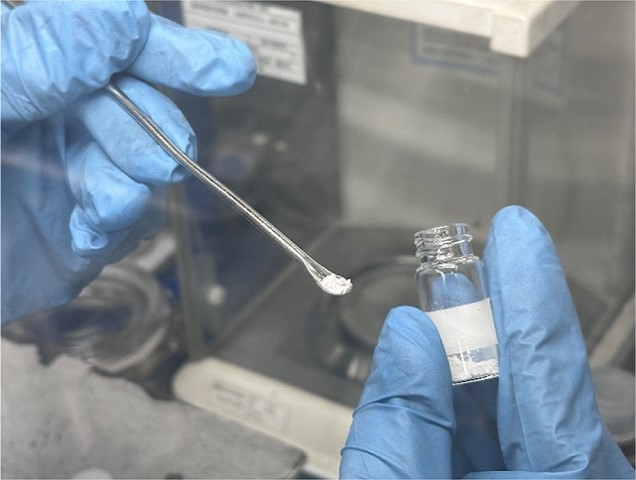

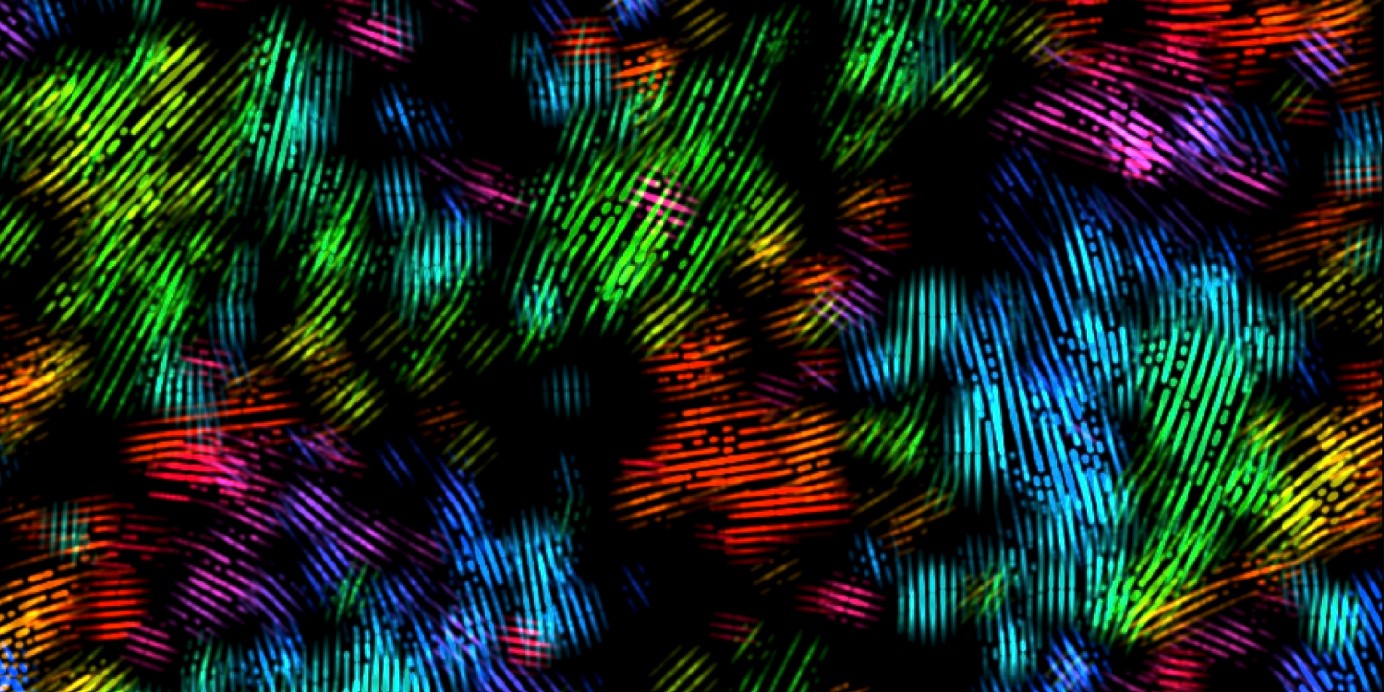

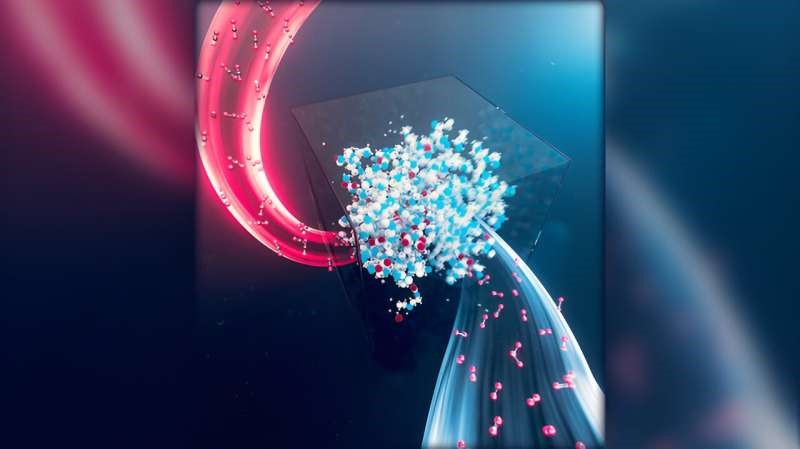

Figure 1. Nature-Inspired Patterns Enhance Polymer Strength

A study published in Nature details how Sottos and her colleagues employed frontal polymerization—a method that uses heat to trigger chemical reactions forming polymers—to mimic nature's approach. Figure 1 shows Nature-Inspired Patterns Enhance Polymer Strength.

In a 2021 study, Sottos and her team established frontal polymerization as a reliable technique for producing biologically inspired polymer materials. Their latest innovation builds on this foundation, enabling the controlled formation of crystalline patterns within these materials, significantly improving toughness and durability.

“Nature fascinates us with spontaneous patterns formed through dissipative processes, yet in synthetic materials, we often rely on precise, controlled methods to create structure,” remarked Beckman researcher Jeff Moore.

Moore, also the Stanley O. Ikenberry Research Professor and professor emeritus of chemistry at Illinois, played a key role in refining the chemical formulations that led to the findings discussed in the Nature paper.

“Our work represents a new frontier—patterning materials without molds or milling, which results in unique properties stemming from this added structure,” he noted. By employing the morphogenic manufacturing technique, the team made minor adjustments to the chemical reactions to create a crystalline pattern.

“Determining the optimal reaction conditions took several weeks, but witnessing the spin-mode dynamics that resulted in these remarkable changes in the patterned microstructure and material properties was especially rewarding,” said lead author Justine Paul, a former Beckman Institute Graduate Fellow.

The result was a material featuring both amorphous (unstructured) regions and crystalline solid areas. This contrast between rubbery and rigid materials enhances product resilience. Additionally, the development of a new method to control the architecture of polymers was made possible through interdisciplinary collaborations at the Beckman Institute.

Cecilia Leal, a professor of materials science and engineering, utilized X-ray scattering to examine how polymer chains align in the patterned material. This technique underscored the significance of understanding the holistic structure-property relationships from molecules to bulk materials, she noted.

Aerospace engineering professor Philippe Geubelle concentrated on modeling the manufacturing process, emphasizing the thermo-chemical instabilities that result in unique heterogeneous materials.

“The close collaboration between experimentalists and modelers, as well as between researchers in mechanics, materials science, and chemistry, was crucial to the success of this project,” Geubelle stated.

Sottos, Moore, Leal, and Geubelle are all members of the Autonomous Materials Systems Working Group at the Beckman Institute.

“This achievement required the combined expertise of an interdisciplinary team, making the collaborative environment of the Beckman Institute ideal for such a breakthrough,” Moore remarked.

Source:Lab Manager

Cite this article:

Janani R (2024), Nature-Inspired Designs Enhance Polymer Durability, AnaTechMaz, pp. 70