Combating Antibiotic Resistance with Graphene and Magnets

Researchers Achieve 99.9% Bacteria Reduction on Surfaces Using Innovative Technique

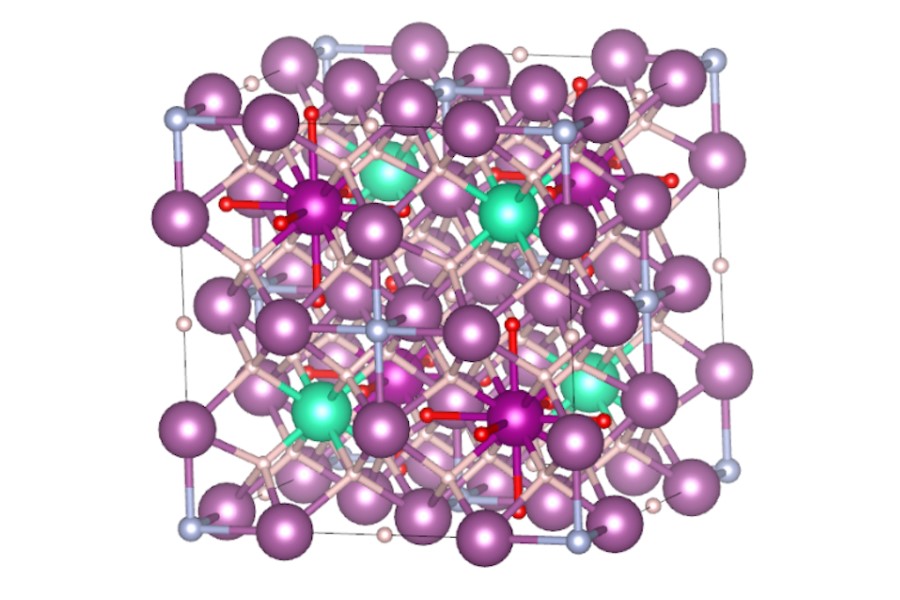

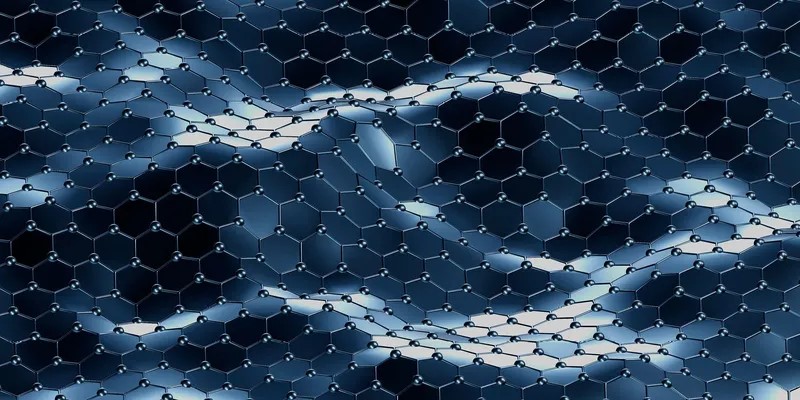

Graphene, known for its strong bactericidal properties, holds promise in combating antibiotic-resistant bacteria. However, effective methods to harness these properties in healthcare have been lacking. A team from Chalmers University of Technology in Sweden has addressed this challenge by utilizing technology similar to that found in standard fridge magnets. This innovation has led to the development of an ultra-thin, acupuncture-like coating that can be applied to catheters and implants, successfully killing 99.9% of bacteria on treated surfaces.

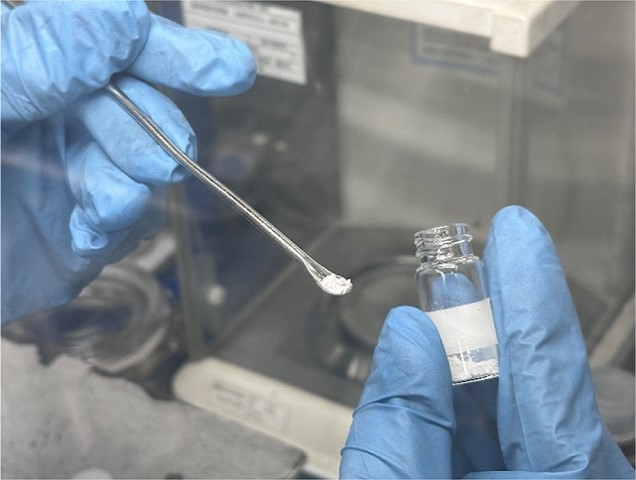

Figure 1. Graphene and Magnets Combat Antibiotic Resistance

Healthcare-associated infections are a significant global issue, leading to considerable suffering, high medical costs, and an increased risk of antibiotic resistance. Many infections arise from the use of medical devices like catheters, hip and knee prostheses, and dental implants, allowing bacteria to enter the body through foreign surfaces. Researchers at Chalmers University have investigated how graphene, a two-dimensional material composed of a single layer of carbon atoms, can help combat antibiotic resistance and infections in the medical field. Previous studies have demonstrated that vertically oriented graphene flakes can prevent bacterial adhesion, effectively slicing bacteria upon contact and leading to their destruction. Figure 1 shows Graphene and Magnets Combat Antibiotic Resistance.

"We are developing an ultra-thin, graphene-based antibacterial material that can be applied to any surface, including biomedical devices, surgical surfaces, and implants to inhibit bacterial attachment. Since graphene physically prevents bacteria from adhering to surfaces, it reduces the risk of developing antibiotic resistance, unlike traditional chemical alternatives such as antibiotics," explains Ivan Mijakovic, Professor of Systems Biology at Chalmers University and a co-author of the study recently published.

Eliminates 99.99% Of Bacteria on Surfaces

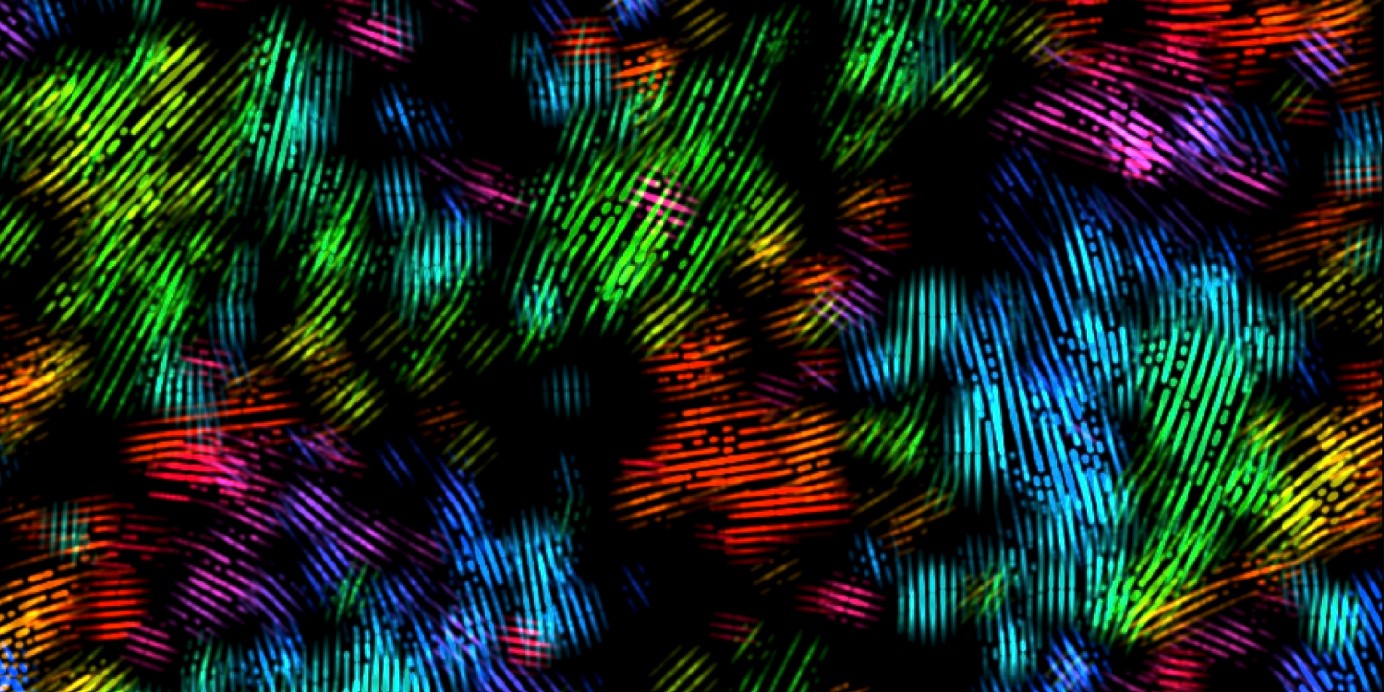

Researchers have encountered a challenge in harnessing graphene's bactericidal properties. While these properties can be effectively demonstrated in the lab, controlling the orientation of the graphene flakes for application on medical devices has proven difficult. Previously, the orientation could only be managed in one specific direction, dictated by the manufacturing process. However, the team at Chalmers University has made a promising breakthrough that could enhance practical applications in healthcare and beyond.

"We have discovered a method to control the effects of graphene in multiple directions with a high level of uniformity," says Roland Kádár, Professor of Rheology at Chalmers University of Technology. "This new orientation technique enables us to integrate graphene nanoplates into medical plastic surfaces, creating an antibacterial surface that eliminates 99.9% of bacteria attempting to attach. This advancement offers significantly greater flexibility for manufacturing bacteria-killing medical devices using graphene."

Unprecedented Efficiency Achieved Through Magnetic Field Control

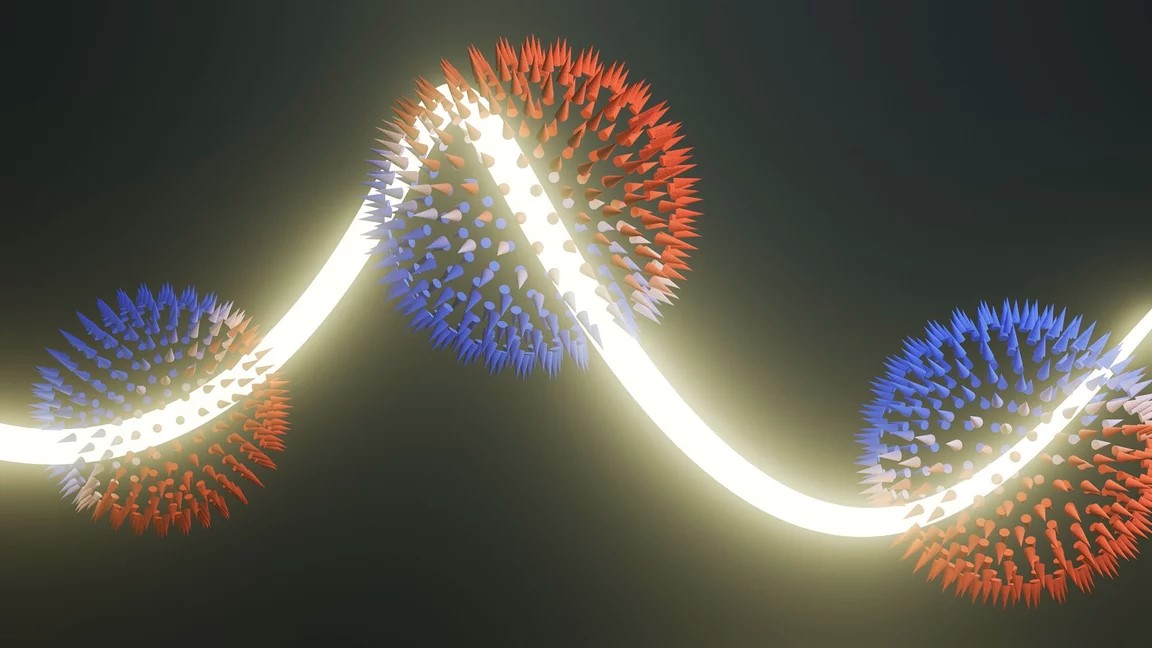

By arranging earth magnets in a circular configuration, the researchers created a magnetic field that aligned uniformly in a straight direction, resulting in a high bactericidal effect on surfaces of various shapes through uniform graphene orientation.

This method, detailed in Advanced Functional Materials, is known as the "Halbach array." It enhances and stabilizes the magnetic field within the array while reducing it on the opposite side, facilitating strong, unidirectional graphene orientation. This technology resembles that found in standard refrigerator magnets.

"This is the first application of the Halbach array method for orienting graphene in a polymer nanocomposite. With these promising results, we aim to introduce graphene plates into the healthcare sector to decrease healthcare-related infections, alleviate patient suffering, and combat antibiotic resistance," says Viney Ghai, a researcher in Rheology and Processing of Soft Matter at Chalmers University of Technology.

The new orientation technology also shows significant potential in various fields, including batteries, supercapacitors, sensors, and durable, water-resistant packaging materials.

"Given its wide-ranging implications, this method truly opens new horizons in material alignment, providing a powerful tool for the successful design and customization of nanostructures that mimic the complex architectures found in nature," adds Roland Kádár.

Source:Lab Manager

Cite this article:

Janani R (2024), Combating Antibiotic Resistance with Graphene and Magnets, AnaTechmaz, pp. 68