Robotics in Construction: Tackling Challenges & Boosting Efficiency

Robotics in construction is enhancing safety and cutting costs, transforming the industry. The construction sector faces numerous challenges, such as recruitment shortages, sustainability issues, and the ongoing need for improved worker safety. In this context, Dave Walsha, Director of Sales and Marketing at drive system supplier EMS, discusses how embracing robotics in construction could offer effective solutions.

Addressing Staffing Shortages in the Construction Industry

While robotics has transformed the industrial and automotive sectors, its adoption in construction has been limited. However, it has the potential to tackle many of the industry's ongoing challenges.

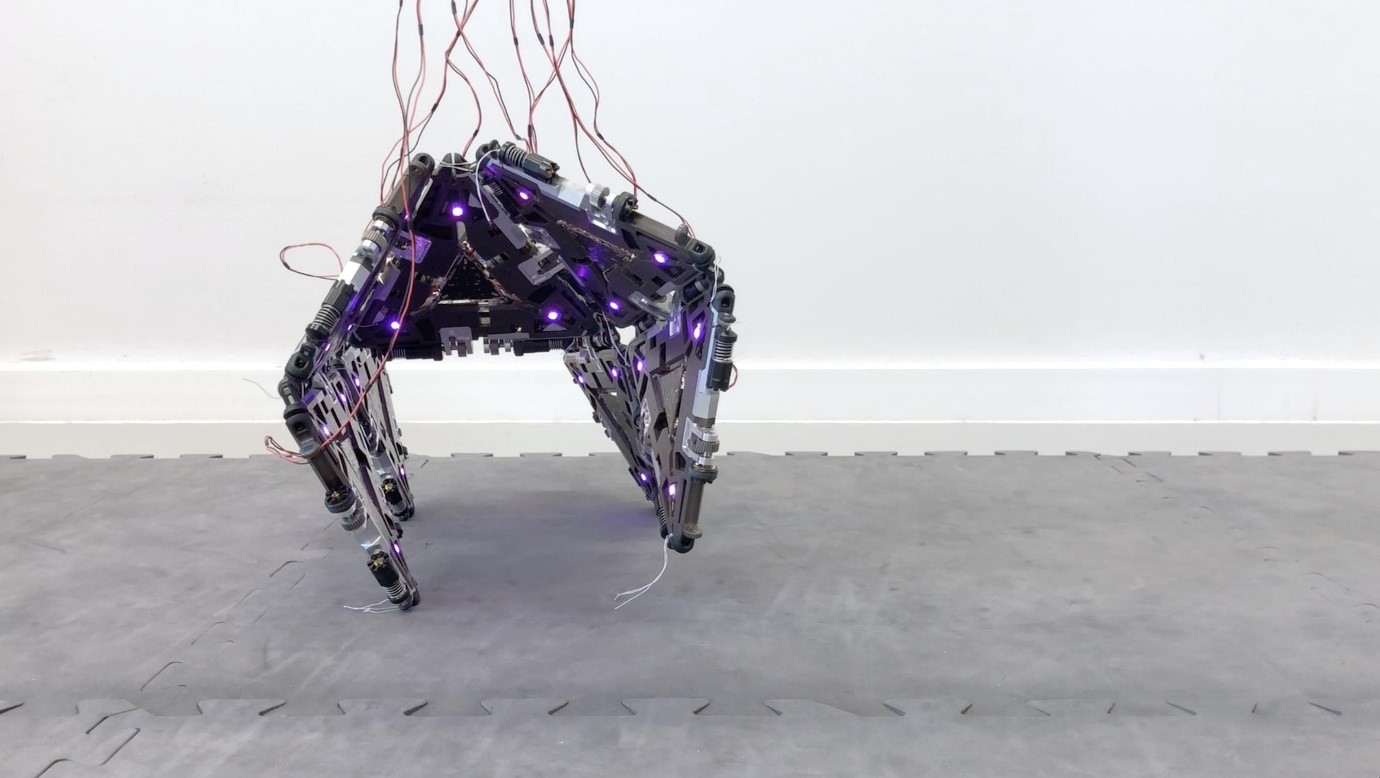

Figure 1. Various hydraulic robots in construction

According to the British Chambers of Commerce's Quarterly Recruitment Outlook, 82% of construction firms struggle to find the right talent. Specialized skills like welding are in short supply, and with many workers nearing retirement, there is insufficient new talent to meet future demand. Robotics could ease these staffing shortages by automating repetitive tasks, such as welding, freeing human workers to focus on more complex roles without overburdening them [1]. Figure 1 shows Various hydraulic robots in construction.

Moreover, a 2024 YouGov survey found that 68% of UK adults would not consider a career in construction. The survey revealed that 69% of respondents viewed the industry as ‘strenuous,’ 52% as ‘dirty,’ and only 12% as ‘forward-thinking.’ By embracing technology and incorporating robotics and drones into construction, the industry could improve its image, attract and retain talent, and address concerns about physical strain and safety.

Enhancing Worker Safety with Robotics

Safety is closely linked to worker retention, and robotics can play a key role in reducing risks. Hazardous tasks, like asbestos removal, often require workers to wear restrictive protective gear, which limits mobility and productivity. Additionally, exposure regulations restrict how long employees can work with asbestos each day, making removal projects both costly and time-consuming.

By utilizing remotely operated robots, both employee health risks and project timelines can be greatly reduced.

The construction industry accounts for over half of all fatal falls across sectors. Robots can be deployed to safely operate in high-risk areas, such as icy offshore platforms, helping to prevent potentially catastrophic falls.

Promoting Sustainability Through Automation in Construction

Approximately 32% of landfill waste originates from construction and demolition. Manual waste sorting is both time-consuming and hazardous, exposing workers to sharp or contaminated materials. Automation can help streamline the sorting process, reducing landfill contributions and enhancing recycling efforts for more sustainable operations.

Why Robotics in Construction Has Yet to Reach Full Adoption

Despite the numerous benefits, robotics adoption in construction remains limited. A 2024 BuiltWorlds report revealed that 35% of construction companies use autonomous heavy equipment, but only 6% have implemented prefabrication robots. Unlike standardized manufacturing environments, construction sites are highly variable, presenting unique challenges for robotic integration.

Construction managers must address how robots navigate uneven terrain, fit into lifts, and interact with workers and heavy machinery.

To overcome these challenges, further advancements in robot design, including sophisticated sensing capabilities, are required. Robots need advanced object recognition powered by onboard sensors to navigate construction sites safely. These sensors could include visual sensors using regular cameras and image processing technology, or Light Detection and Ranging (LiDAR), which uses near-infrared light.

The Importance of DC Motor Technology in Robotics for Construction

While enhancing a robot's "thinking" capabilities is essential, its physical performance is equally critical. The choice of motor technology plays a key role in determining a robot’s ability to execute tasks efficiently and reliably. In the context of construction robotics, motor selection is crucial for ensuring optimal performance across various tasks.

Advancements in motor technology have made DC motors lighter and more powerful than ever. However, selecting the right motor for a specific application is key to achieving the best results. For instance, a robot used in construction for gripping and placing objects requires motors with sufficient torque to hold materials securely without causing damage. On the other hand, stepper motors are ideal for tasks that require precision, such as welding.

Stepper motors move in precise increments, offering excellent positional accuracy, which is essential for detailed tasks in construction robotics [2]. In contrast, brushless DC motors are better suited for tasks that prioritize speed and power, such as lifting heavy materials or transporting loads, where torque is needed across varying speeds.

Building a Safer, More Sustainable Future with Robotics in Construction

The construction industry must adopt technology to attract talent, enhance safety, and achieve sustainability goals. Robotics in construction, driven by advanced DC motors, has the potential to modernize the sector, allowing companies to build more efficiently while maintaining high-quality standards.

References:

- https://www.eurekamagazine.co.uk/content/technology/how-robotics-in-construction-is-overcoming-industry-challenges-and-improving-efficiency/

- https://www.hp.com/us-en/printers/site-print/robotics-in-construction-helping-creation-more-precise-execution.html

Cite this article:

Janani R (2025), Robotics in Construction: Tackling Challenges & Boosting Efficiency, AnaTechMaz, pp. 122