A Leap Forward in Material Diversity and Robotic Innovation

The realm of 3D printing has undergone a revolutionary transformation, propelled by cutting-edge technology developed collaboratively by researchers at ETH Zurich and a forward-thinking US start-up. Gone are the days when the technology was confined to fast-curing plastics; now, it embraces the versatility of slow-curing polymers, unlocking a myriad of possibilities for creating complex, durable robots with enhanced elastic properties.

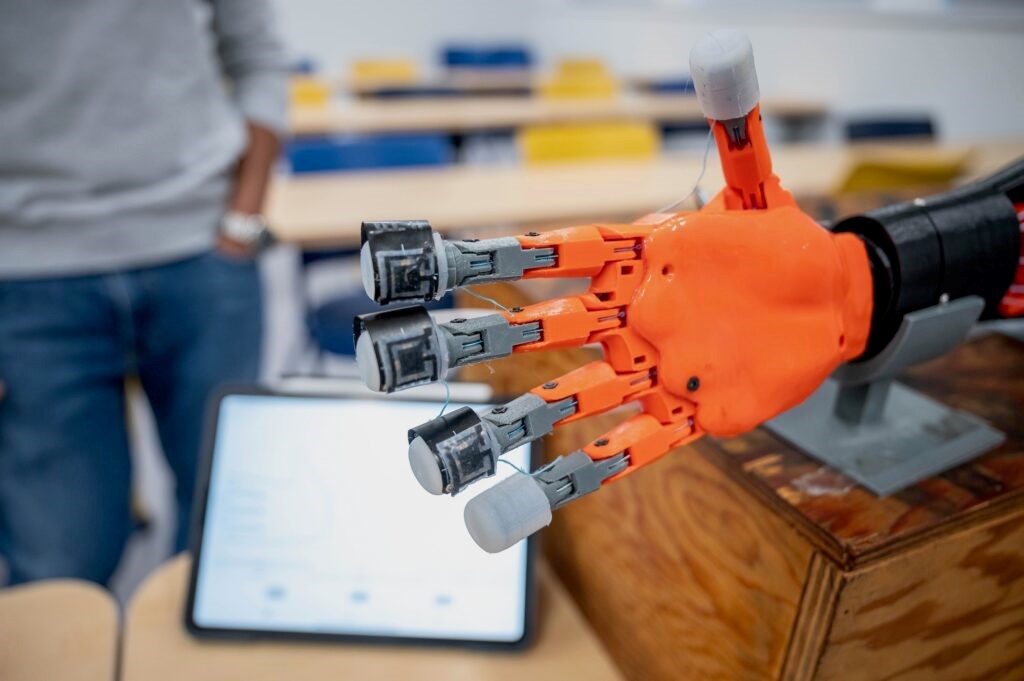

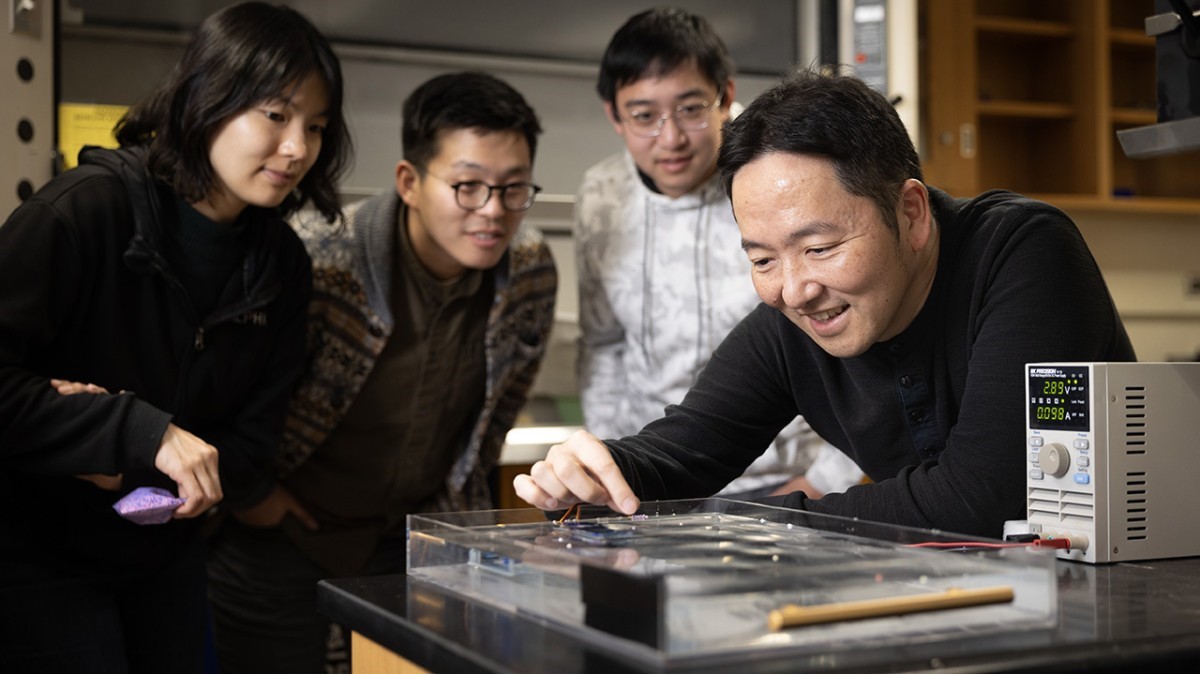

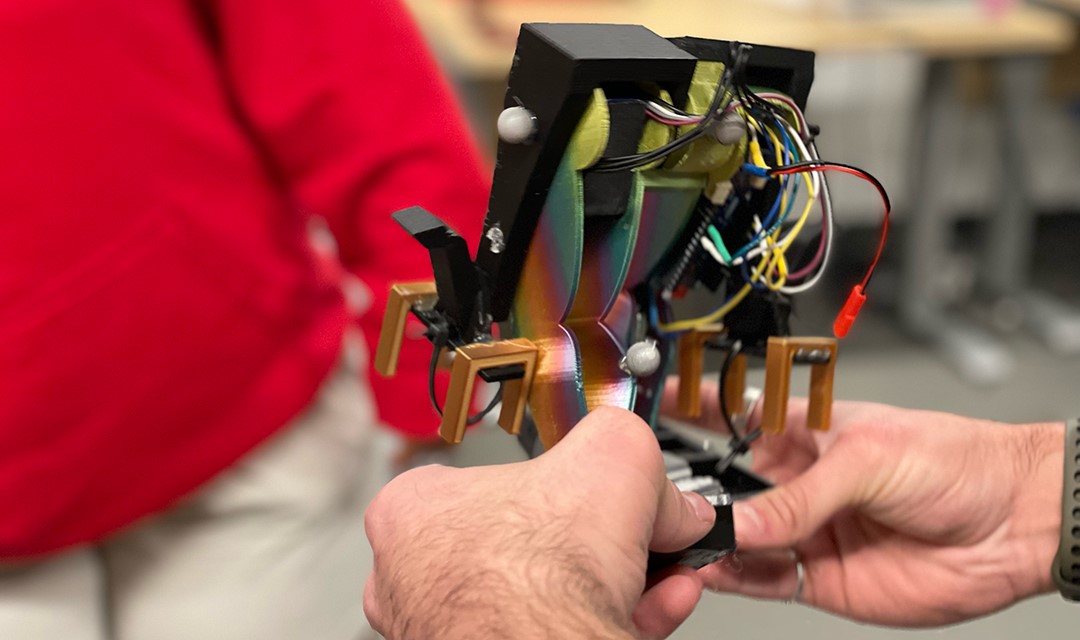

Figure 1. 3D Printed Hand. (Credit: ETH Zurich/Thomas Buchner)

Diving into the Technological Breakthrough

Figure 1 shows a robotic hand made of varyingly rigid and elastic polymers. In a groundbreaking development, the research team at ETH Zurich has harnessed the power of slow-curing thiolene polymers, a material that boasts superior elastic properties and a rapid return to its original state after bending. This breakthrough has enabled the creation of a robotic hand complete with bones, ligaments, and tendons—all crafted seamlessly in one printing process.

Advantages of Slow-Curing Polymers

Unlike their fast-curing counterparts, thiolene polymers offer a unique advantage in 3D printing, allowing for the production of intricate structures and parts with cavities. The elastic nature of these polymers proves ideal for crafting ligaments in the robotic hand, showcasing a level of flexibility and durability that was previously unattainable.

Fine-Tuning Stiffness for Soft Robotics

One notable feature of thiolene polymers is their adjustable stiffness, a characteristic that can be finely tuned to meet the specific requirements of soft robotics. Professor Robert Katzschmann from ETH Zurich highlights the advantages of soft robots, emphasizing their reduced risk of injury when working alongside humans and their suitability for handling delicate objects.

Revolutionizing the 3D Printing Process

Traditional 3D printing involves layer-by-layer deposition of material, typically followed by scraping to address surface irregularities. However, slow-curing polymers posed a challenge to this method. Enter a game-changing solution: the integration of a 3D laser scanner. This addition checks each printed layer for irregularities, providing real-time feedback to adjust the amount of material needed for the next layer. This innovative approach eliminates the need for post-curing scraping and adapts seamlessly to the unique properties of slow-curing polymers.

The Driving Force: Inkbit's Contribution

Behind this groundbreaking technology is the contribution of Inkbit, an MIT spin-off. Responsible for developing the new printing technology, Inkbit plans to offer a 3D printing service to its customers and introduce the new printers to the market.

Looking Ahead

The collaboration between ETH Zurich and Inkbit has resulted in the publication of their groundbreaking technology and sample applications in the prestigious journal Nature. ETH Zurich's robotics group, led by Professor Katzschmann, is poised to explore further possibilities and design even more sophisticated structures, while Inkbit aims to bring the advantages of this new technology to a broader audience through its 3D printing service and printer sales.

The marriage of slow-curing polymers and advanced 3D printing technology marks a significant milestone in the evolution of robotics and manufacturing. This breakthrough opens doors to unparalleled possibilities, from crafting intricate robotic components to enhancing the safety and efficiency of robots working alongside humans. As we venture further into this new era of 3D printing, the collaboration between research institutions and innovative start-ups promises a future where the boundaries of material science and robotic design are continually pushed and redefined.

Source: ETH Zurich

Cite this article:

Hana M (2023), A Leap Forward in Material Diversity and Robotic Innovation, AnaTechMaz, pp. 8