Predictive maintenance using AI and IoT

Predictive maintenance using AI and IoT is a technique that uses data from sensors and other IoT devices to predict when equipment is likely to fail and proactively perform maintenance to prevent downtime. By detecting potential issues before they become major problems, businesses can save money on maintenance costs and avoid costly downtime.

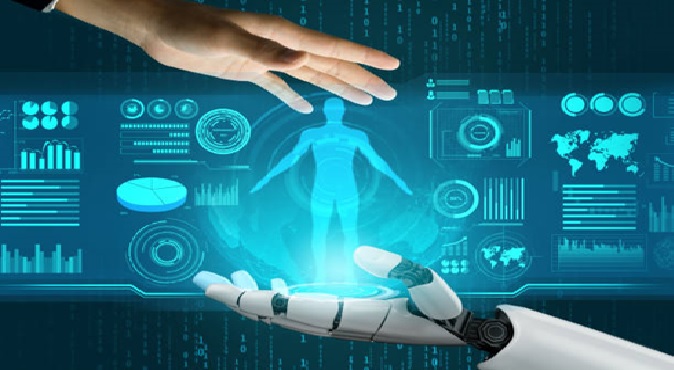

AI algorithms are used to analyze the data from IoT sensors and identify patterns that indicate equipment failure. These algorithms can detect subtle changes in vibration, temperature, and other indicators that may be missed by human operators. Once a potential issue is detected, the system can alert maintenance staff and schedule repairs before the equipment fails.

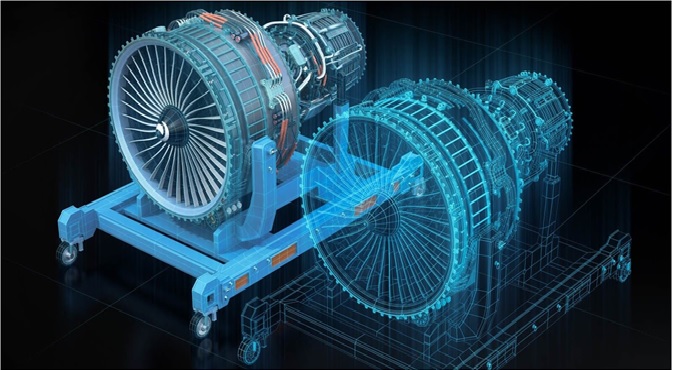

Figure 1. Predictive maintenance using AI and IoT

Figure 1 shows Predictive maintenance using AI and IoT. Benefits of Predictive Maintenance

According to a report by PwC, on average, predictive maintenance in factories could:

- Reduce costs by 12%

- Improve uptime by 9%

- Reduce safety, health, environment, and quality risks by >4%

- Extend the lifetime of an aging asset by 20% [1]

Reduced downtime: By detecting potential equipment failures before they occur, predictive maintenance can help businesses avoid unexpected downtime. This can save businesses significant amounts of money by reducing lost production time and minimizing the need for emergency repairs.

Lower maintenance costs: Predictive maintenance can help businesses to optimize their maintenance schedules and avoid unnecessary maintenance tasks. This can help to reduce maintenance costs by focusing maintenance efforts where they are most needed.

Increased equipment lifespan: By detecting potential issues early, predictive maintenance can help businesses to address problems before they cause significant damage. This can help to extend the lifespan of equipment and reduce the need for premature replacements.

Improved safety: Predictive maintenance can help to identify potential safety hazards before they cause harm. This can help to keep workers safe and reduce the risk of accidents.

Improved productivity: By reducing downtime and optimizing maintenance schedules, predictive maintenance can help businesses to improve their productivity. This can help to increase output and revenue.

Data-driven decision making: Predictive maintenance uses data from IoT sensors and AI algorithms to make maintenance decisions. This data can provide valuable insights into equipment performance and maintenance needs, allowing businesses to make data-driven decisions.

Environmental benefits: Predictive maintenance can help businesses to reduce their environmental impact by reducing energy consumption and emissions. By optimizing maintenance schedules, businesses can reduce the energy used by equipment and minimize the waste generated by maintenance activities.

Overall, predictive maintenance using AI and IoT is an exciting area of research with many potential applications in a variety of industries, from manufacturing and transportation to healthcare and energy. As these technologies continue to evolve, we can expect to see more businesses adopting predictive maintenance strategies to improve their efficiency and reduce costs.

References:

- https://www.itconvergence.com/blog/5-benefits-iot-based-predictive-maintenance/

Cite this article:

Hana M (2023), Predictive maintenance using AI and IoT, AnaTechMaz, pp.202