Digital Twins

A digital twin is a virtual replica of a physical object, system, or process. It is a computer model that simulates the behavior of the physical system in real-time, allowing engineers, operators, and other stakeholders to monitor and optimize the system's performance.

Digital twins are used in a wide range of industries, including manufacturing, aerospace, automotive, healthcare, and energy. They can be used to improve the design and operation of complex systems, reduce downtime, and optimize performance.

Figure 1. example of a digital twin. [1]

Figure 1 shows an example of a digital twin. Digital twins offer several benefits, including:

Improved performance: Real-time information and insights provided by digital twins let you optimize the performance of your equipment, plant, or facilities. Issues can be dealt with as they occur, ensuring systems work at their peak and reduce downtime. [2]

Predictive maintenance: By simulating the behavior of physical systems, digital twins can predict when maintenance is needed, allowing for proactive maintenance and reducing the risk of equipment failure.

Reduced costs: Digital twins can help reduce costs by optimizing energy consumption, improving production processes, and reducing downtime.

Better decision-making: Digital twins provide real-time data and analytics, enabling better decision-making and faster problem resolution.

Improved safety: Digital twins can be used to simulate and test safety scenarios, reducing the risk of accidents and injuries.

Product end-of-life: Digital twins can even help manufacturers decide what to do with products that reach the end of their product lifecycle and need to receive final processing, through recycling or other measures. By using digital twins, they can determine which product materials can be harvested.

Digital twin technology is being used across a wide range of industries, including:

Manufacturing: Digital twins are used across the whole manufacturing lifecycle, from designing and planning to maintaining existing facilities. A digital twin prototype allows you to monitor your equipment at all times and analyze performance data that shows how a particular part or the entirety of your plant is functioning. [2]

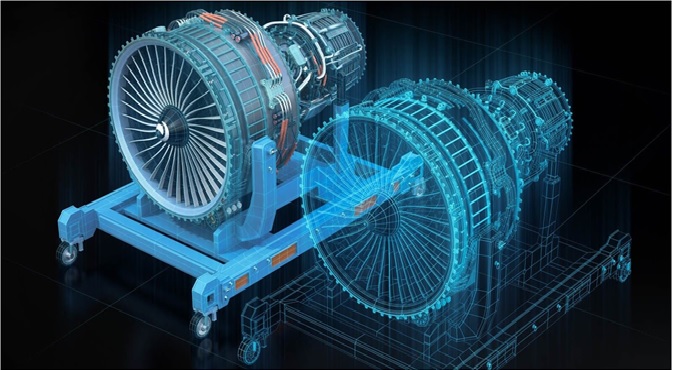

Aerospace: Digital twins are used to monitor the performance of aircraft and spacecraft, predict maintenance needs, and improve safety.

Automotive: The automotive industry uses digital twins to create digital models of vehicles. Digital twins can give you insights into the physical behavior of the vehicle as well as software, mechanical, and electrical models. It is another area where predictive maintenance is valuable because a digital twin can alert a service center or user when it finds an issue with component performance. [2]

Healthcare: Digital twins are used to simulate human physiology, test treatments, and predict the effects of different drugs

There are several types of digital twin, including:

Component twins/Parts twins: Component twins are the basic unit of digital twin, the smallest example of a functioning component. Parts twins are roughly the same thing, but pertain to components of slightly less importance. [3]

Asset twins: When two or more components work together, they form what is known as an asset. Asset twins let you study the interaction of those components, creating a wealth of performance data that can be processed and then turned into actionable insights. [3]

System or Unit twins: The next level of magnification involves system or unit twins, which enable you to see how different assets come together to form an entire functioning system. System twins provide visibility regarding the interaction of assets, and may suggest performance enhancements. [3]

Process twins: Process twins, the macro level of magnification, reveal how systems work together to create an entire production facility. Are those systems all synchronized to operate at peak efficiency, or will delays in one system affect others? Process twins can help determine the precise timing schemes that ultimately influence overall effectiveness. [3]

In summary, digital twins are a powerful tool for optimizing the performance of complex systems and improving decision-making in a wide range of industries.

References:

- https://www.thedigitalspeaker.com/digital-twins-building-block-metaverse/

- https://aws.amazon.com/what-is/digital-twin/

- https://www.ibm.com/in-en/topics/what-is-a-digital-twin

Cite this article:

Hana M (2023), Digital Twins, AnaTechMaz, pp.199