Thermography in engineering

Thermography involves the use of thermal imagers, which are sophisticated devices that measure the natural emission of infrared radiation from a heated object to produce a thermal picture or video. Modern infrared cameras are portable and easy to operate, meaning that they can be used for many different applications.

Objects emit electromagnetic energy when heated, with more energy being released as the temperature increases. This energy is emitted as a wave which travels at the speed of light.[1]

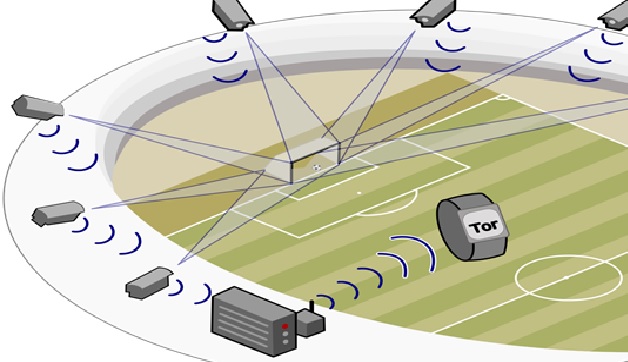

Figure 1. Thermography in Engineering

Figure 1 shows Infrared thermography is an accepted and applied technology for the non-contact inspection of a variety of industrial assets. This technology allows the user to easily see abnormal thermal patterns which may indicate potential faults, defects, or other system inefficiencies. Although the potential number of thermography applications is nearly endless, many users have the idea that thermography is mostly applicable to electrical applications only, and so miss the many other uses that present themselves in an industrial setting.

This brief 20-30 minute webinar with FLIR Strategic Business Development Manager, Rob Raymer, will review the technology of infrared thermography and discuss a variety of lesser known mechanical applications that are well suited for thermographic inspection. [3]

This is explained in the formula:

Incident Radiant Power = Emitted Radiant Power + Transmitted Radiant Power + Reflected Radiant Power

The incident radiant power is the profile as viewed through a thermal imaging camera, emitted radiant power is the energy that is intended to be measured, transmitted radiant power is that which passes through the object from a remote thermal source, and reflected radiant power is the energy that is reflected from the object from a remote thermal source. [1]

Types of thermography include:

- Passive thermography - The features of interest are naturally at a higher or lower temperature than the background. It has many applications such as surveillance of people and medical diagnosis (specifically thermology).

- Active thermography - An energy source is required to produce a thermal contrast between the feature of interest and the background. The active approach is necessary in many cases given that the inspected parts are usually in equilibrium with the surroundings.

Thermography inspections utilize the surface temperature distribution of an object. If the surface temperature is uniform, with no temperature variations, there is no indication of a problem. As a result, for some applications it has limitations.

Important advantages of using thermography:

- Inspection can take place during production.

- Inspection is quick and does not require physical contact.

- Results are recorded digitally.

- Costs are relatively low. [2]

References:

- https://www.twi-global.com/technical-knowledge/faqs/what-is-thermography-in-engineering

- https://www.corrosionpedia.com/definition/1085/thermography

- https://www.flir.in/support-center/training/thermography-training/webinars/an-overview-of-thermography-for-mechanical-applications/

Cite this article:

Thanusri swetha J (2021) Thermography in engineering, AnaTechMaz, pp. 51