Hydrogel-Based Robotic Hand Endures Poking, Burning and Cutting to Advance Tactile Sensing

Humanoid bipedal robots—like those from Boston Dynamics—continue to make impressive strides, but they still fall short of their boldest science fiction counterparts. One major hurdle remains: the ability to truly feel sensations like a human. While scientists have experimented with various sensors to give robots a basic sense of touch, these solutions tend to be expensive, imprecise, and usually limited to sensing just one type of stimulus at a time.

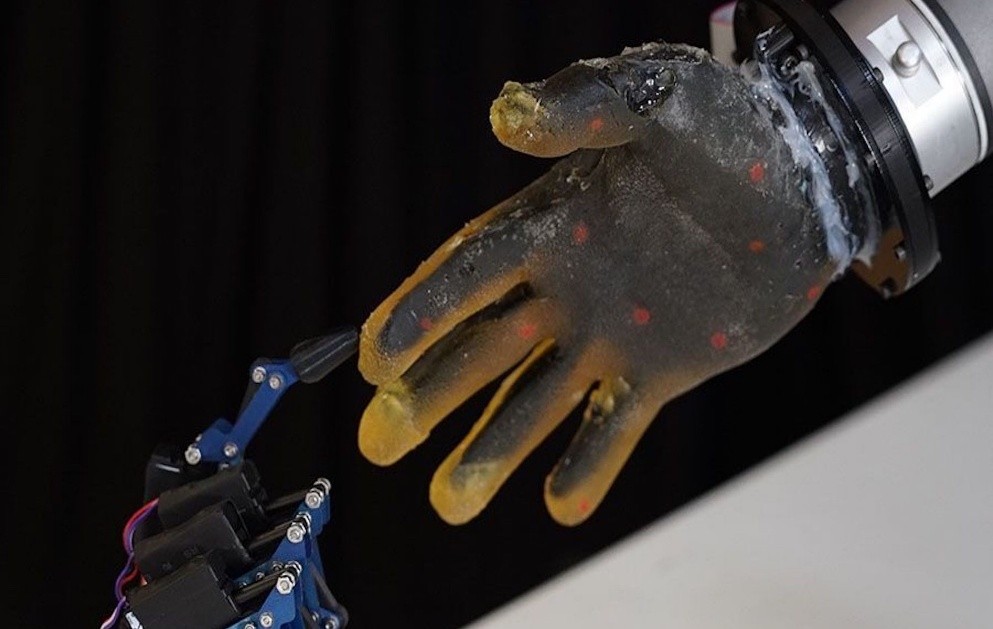

Figure 1. Hydrogel Robotic Hand Withstands Heat, Pressure, and Damage to Enhance Touch Sensitivity.

That could soon change. A team of researchers from the University of Cambridge and University College London has created a new kind of responsive “synthetic skin.” Crafted from a single hydrogel, this innovative material can detect touch, pressure, temperature changes, and even physical damage—bringing robotic sensation one step closer to mimicking real human skin. Figure 1 shows Hydrogel Robotic Hand Withstands Heat, Pressure, and Damage to Enhance Touch Sensitivity.

The team successfully molded the hydrogel into the shape of a human hand and fitted it onto a robot like a glove. With this thick, flesh-like covering, the robot gains a much more accurate sense of touch, allowing it to better interact with its surroundings. While still in the early stages of development, the researchers believe this synthetic skin could eventually enhance robot performance in factories, hazardous environments, and disaster response scenarios. Their findings were published this week in Science Robotics.

The concept of synthetic skin in robotics isn't entirely new. As far back as 2016, scientists have been using small sensors embedded in robotic hands and fingertips to help machines detect the shape and texture of objects. However, implementing this technology has typically been complex. For example, enabling a robotic hand to sense both heat and pressure would require two distinct types of sensors, each tailored to detect a specific stimulus.

The problem is, these different sensors can interfere with each other, a phenomenon known as “cross talk.” This overlap of signals can reduce sensory accuracy and even risk damaging the sensors. Moreover, cramming multiple sensors into the limited space of a robotic hand increases system complexity—making errors more likely.

“Using separate sensors for each type of touch results in materials that are complicated to manufacture,” explained lead author and Cambridge professor David Hardman in a statement. “Our goal was to create a single material that can detect multiple kinds of touch at the same time.”

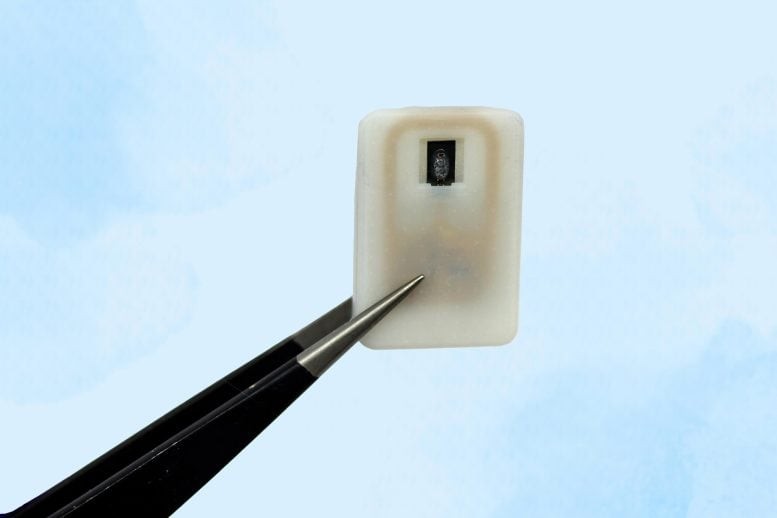

To achieve this, the researchers developed a soft, stretchable, and conductive gelatin-based hydrogel. This material is able to convert physical inputs—such as heat, pressure, and damage—into electronic signals that a computer can interpret. Rather than relying on multiple sensors, the hydrogel itself contains about 860,000 individual signal pathways embedded within it, allowing it to process a wide range of sensory data. The team tested the synthetic skin under various physical conditions to calibrate its sensitivity and refine its performance.

The synthetic skin is also highly versatile—it can be melted down and reshaped as needed. In this study, the researchers wanted to determine whether the material would still function effectively when molded into the form of a human hand. The result was a striking yellow-and-black hand that resembled a worn construction glove. This custom-molded skin was fitted over a robot's hand, and researchers conducted simple tests by pressing it with a finger and gently swabbing the surface. Even in this more realistic, glove-like form, the synthetic skin successfully detected and distinguished between varying levels of pressure.

The researchers then subjected the robotic hand to harsher conditions, including a "heat blast" that partially melted the material, followed by slicing it open with a scalpel. Despite the damage, the synthetic skin was still able to detect each type of stimulus—heat, pressure, and physical trauma—using just one unified sensing system. Although the material hasn't yet reached the sensitivity of human skin, it outperformed other methods that rely on multiple separate sensors.

“We’re not quite at the level where the robotic skin is as good as human skin, but we think it’s better than anything else out there at the moment,” said co-author Thomas George Thuruthel from University College London. “Our approach is not only more flexible and easier to manufacture than traditional sensor setups, but we can also calibrate it using human touch for a wide range of applications.”

A Step Toward Robots ‘Feeling’ Their Way Through the World

The researchers explain that all the poking, prodding, and burning served a clear purpose: to show that the synthetic skin remains functional even after being melted down and reshaped to fit different parts of a robot's body. In theory, this adaptable material could be applied across a robot’s surface, allowing it to sense touch across multiple areas.

Equipped with this sensing layer, a robot could better navigate complex environments—whether on an assembly line or a construction site—and interact with its surroundings more like a human. This ability could prove especially important if humanoid robots, like those being developed by companies such as Figure and Tesla, are ever deployed in real-world jobs alongside people. For instance, if a robot is passing a car part to a human, it needs to know whether that part is dangerously hot.

Source: POPULAR SOLUTIONS

Cite this article:

Priyadharshini S (2025), Hydrogel-Based Robotic Hand Endures Poking, Burning and Cutting to Advance Tactile Sensing, AnaTechMaz, pp.348