Advantages of 3D Printing House

Houses that are designed and built using construction technologies that use the 3D printing method are known as 3D printed homes. 3D printed homes are faster to build and are superior to the traditionally constructed structures in many ways.

The process of building a 3D-printed home is not just different but a lot quicker than conventional construction. It is built with focus on reduced build-time, zero-waste construction and optimised production. To start with, the structure was printed using a special concrete mix through which large-scale 3D structures were made. The concrete mix is a base of ordinary cement which has a lower water-cement ratio. [1]

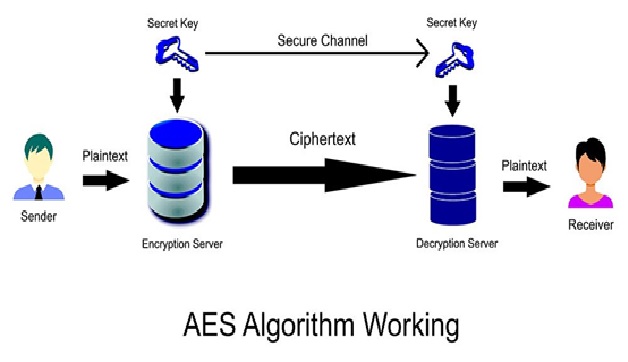

Figure 1. Advantages of 3D Printing House

Figure 1 shows the findings revealed that houses built using additive manufacturing and 3D-printed materials were more environmentally favorable. The conventional construction method had higher impacts when compared to the 3D-printing method with global warming potential of 1154.20 and 608.55 kg CO2 eq, non-carcinogenic toxicity 675.10 and 11.9 kg 1,4-DCB, and water consumption 233.35 and 183.95 m3, respectively. [2]

Advantages of 3D Printing House

1. Flexible Design

3D printing allows for the design and print of more complex designs than traditional manufacturing processes. More traditional processes have design restrictions which no longer apply with the use of 3D printing.

2. Rapid Prototyping

3D printing can manufacture parts within hours, which speeds up the prototyping process. This allows for each stage to complete faster. When compared to machining prototypes, 3D printing is inexpensive and quicker at creating parts as the part can be finished in hours, allowing for each design modification to be completed at a much more efficient rate.

3. Print on Demand

Print on demand is another advantage as it doesn’t need a lot of space to stock inventory, unlike traditional manufacturing processes. This saves space and costs as there is no need to print in bulk unless required.

The 3D design files are all stored in a virtual library as they are printed using a 3D model as either a CAD or STL file, this means they can be located and printed when needed. Edits to designs can be made at very low costs by editing individual files without wastage of out of date inventory and investing in tools.

4. Strong and Lightweight Parts

The main 3D printing material used is plastic, although some metals can also be used for 3D printing. However, plastics offer advantages as they are lighter than their metal equivalents. This is particularly important in industries such as automotive and aerospace where light-weighting is an issue and can deliver greater fuel efficiency.

5. Fast Design and Production

Depending on a part’s design and complexity, 3D printing can print objects within hours, which is much faster than moulded or machined parts. It is not only the manufacture of the part that can offer time savings through 3D printing but also the design process can be very quick by creating STL or CAD files ready to be printed. [3]

References:

- https://housing.com/news/first-3d-printed-house-india/

- https://cleantechnica.com/2022/01/14/3d-printed-houses-the-future-of-construction-video/

- https://www.twi-global.com/technical-knowledge/faqs/what-is-3d-printing/pros-and-cons

Cite this article:

Thanusri swetha J (2021) Advantages of 3D Printing House, AnaTechMaz, pp. 32