New Platform Enables Rapid Prototyping of Large, Durable Interactive Structures

Prototyping large structures with integrated electronics, such as a chair that monitors posture, is often a time-consuming and wasteful process. Typically, multiple versions of the structure need to be created using 3D printing and laser cutting, generating significant waste. After assembling the frame, sensors and fragile electronics are grafted onto it, and wiring is added to make the device functional. If the prototype fails, it is usually discarded, requiring a complete redesign.

MIT researchers have developed an innovative platform that allows for the iterative design of large, sturdy, interactive structures. This system uses reconfigurable building blocks, or voxels, that integrate both the structure and the electronics. These lightweight, three-dimensional lattice blocks offer high strength and stiffness, as well as sensing, response, and processing capabilities. The platform enables users, even those without mechanical or electrical engineering expertise, to quickly and efficiently create complex, functional interactive devices without the need for separate electronic components.

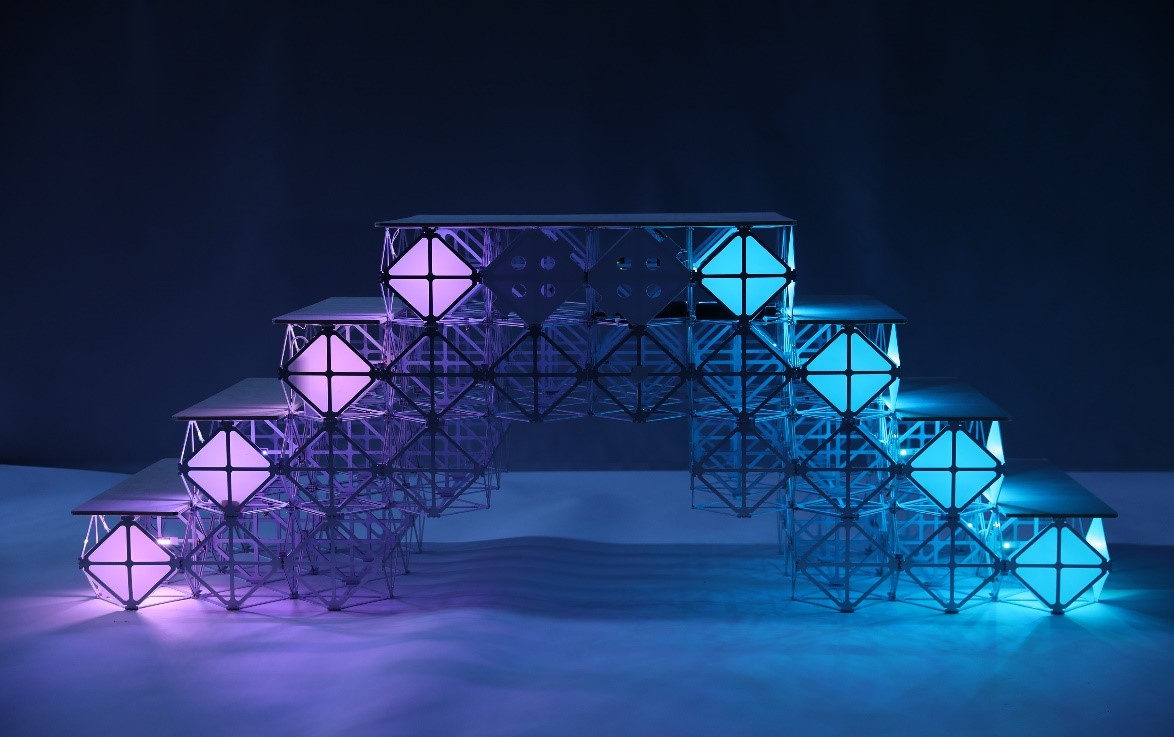

Figure 1. New Platform Enables Rapid Prototyping of Interactive Structures

The VIK (Voxel Invention Kit) prototyping platform uses reconfigurable voxels that cost about 50 cents each and can be assembled, disassembled, and reconfigured into various forms. The platform includes a user-friendly design tool that allows for end-to-end prototyping, enabling users to simulate how structures respond to mechanical loads and make adjustments as needed. According to Jack Forman, an MIT graduate student and co-lead author of a paper on VIK, this approach democratizes access to functional interactive devices, eliminating the need for 3D printing or laser cutting. With just the voxel faces, users can create interactive structures anywhere. Figure 1 shows New Platform Enables Rapid Prototyping of Interactive Structures.

The paper is co-authored by Jack Forman and Miana Smith, both graduate students, along with Amira Abdel-Rahman and senior author Neil Gershenfeld, an MIT professor and director of the CBA. The research will be presented at the Conference on Human Factors in Computing Systems.

Modular Functional Components

VIK builds on years of research at the CBA, advancing discrete cellular building blocks known as voxels. One voxel, made from an aluminum cuboctahedral lattice, can support up to 228 kilograms, roughly the weight of an upright piano.

Rather than using 3D printing, milling, or laser cutting, these voxels are assembled into large, durable structures like airplane parts or wind turbines, capable of responding to environmental changes.

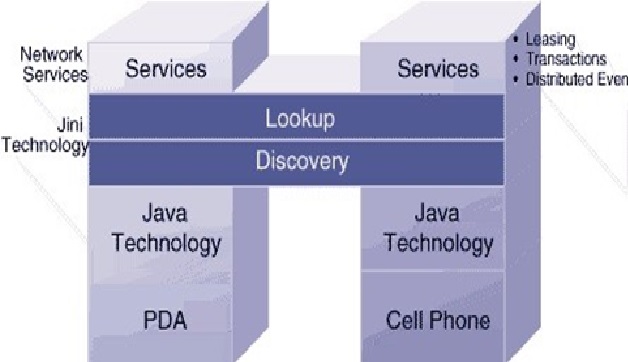

By integrating structural electronics into the voxels, the CBA team developed a system that allows these assembled structures to transmit data, power, and mechanical forces without wires.

To improve usability, the researchers made the voxel design larger, making the lattice structures easier to assemble and disassemble by hand. They also added aluminum cross-bracing to enhance strength and stability.

VIK voxels feature a reversible, snap-fit connection, allowing users to easily assemble them without additional tools, unlike earlier voxel designs that required rivets.

“We designed the voxel faces to ensure only correct connections can be made, so users can be confident they're building the right wiring harness. Once the device is finished, they can simply plug it in and it will work,” says Smith.

This eliminates the costly and often problematic wiring harnesses, which can be a significant source of failure in functional systems.

A User-Friendly Prototyping Platform

To assist users with minimal engineering knowledge in creating interactive devices, the team developed an intuitive interface that simulates 3D voxel structures. This interface includes a Finite Element Analysis (FEA) simulation model, allowing users to design a structure and simulate the forces and mechanical loads on it. The tool highlights potential weak points with color-coded animations to show areas of concern.

"We essentially created a 'Minecraft' for voxel applications," says Forman. "You don't need advanced civil engineering knowledge to ensure your design is safe. With VIK, anyone can confidently build something."

Additionally, users can easily incorporate off-the-shelf components, such as speakers, sensors, or actuators, into their designs. VIK prioritizes flexibility, letting makers use familiar microcontrollers in their projects.

Victor Zaderej, manager of advanced electronics packaging technology at Molex, highlights the Voxel Invention Kit (VIK) as a pivotal step toward the future of electronics, where three-dimensional space will play a key role. He likens VIK to a combination of a LEGO kit and an electronics breadboard, offering endless possibilities for engineers and designers to explore innovative applications.

The VIK design tool provides valuable feedback, allowing users to quickly adjust their prototypes or reassemble the structure into something new. Moreover, the aluminum voxels are fully recyclable, making it easy to discard or repurpose them when needed.

With its reconfigurability, recyclability, high strength, light weight, and integrated electronics, VIK is particularly suitable for fields like theatrical stage design, where temporary, customizable structures are needed. Additionally, it holds potential for space fabrication and the development of smart, sustainable infrastructure in cities.

For the researchers, the key next step is to see how users apply VIK in real-world settings. “These voxels are now so accessible that it will be exciting to see what people can create with VIK,” says Forman.

Source: MIT News

Cite this article:

Janani R (2025), New Platform Enables Rapid Prototyping of Large, Durable Interactive Structures, AnaTechMaz, pp.304