China's Revolutionary Solid-State Deep Ultraviolet Laser Could Redefine Chip Manufacturing

Scientists from the Chinese Academy of Sciences (CAS) have reportedly achieved a significant breakthrough in solid-state deep ultraviolet (DUV) laser technology. A research paper published by the International Society for Optics and Photonics (SPIE) reveals that Chinese researchers have successfully generated a coherent 193 nm (nanometer) laser beam, a critical component in semiconductor photolithography.

If further developed and scaled up, this technology could pave the way for new lithography tools capable of producing advanced semiconductor chips. Currently, semiconductor manufacturing heavily relies on photolithography, a process that uses specialized ultraviolet (UV) lasers to etch intricate patterns onto silicon wafers.

The industry standard for DUV lithography relies on gas-based excimer lasers to produce 193 nm UV light. However, CAS researchers claim to have successfully demonstrated a solid-state laser system capable of emitting this essential wavelength without the use of gas.

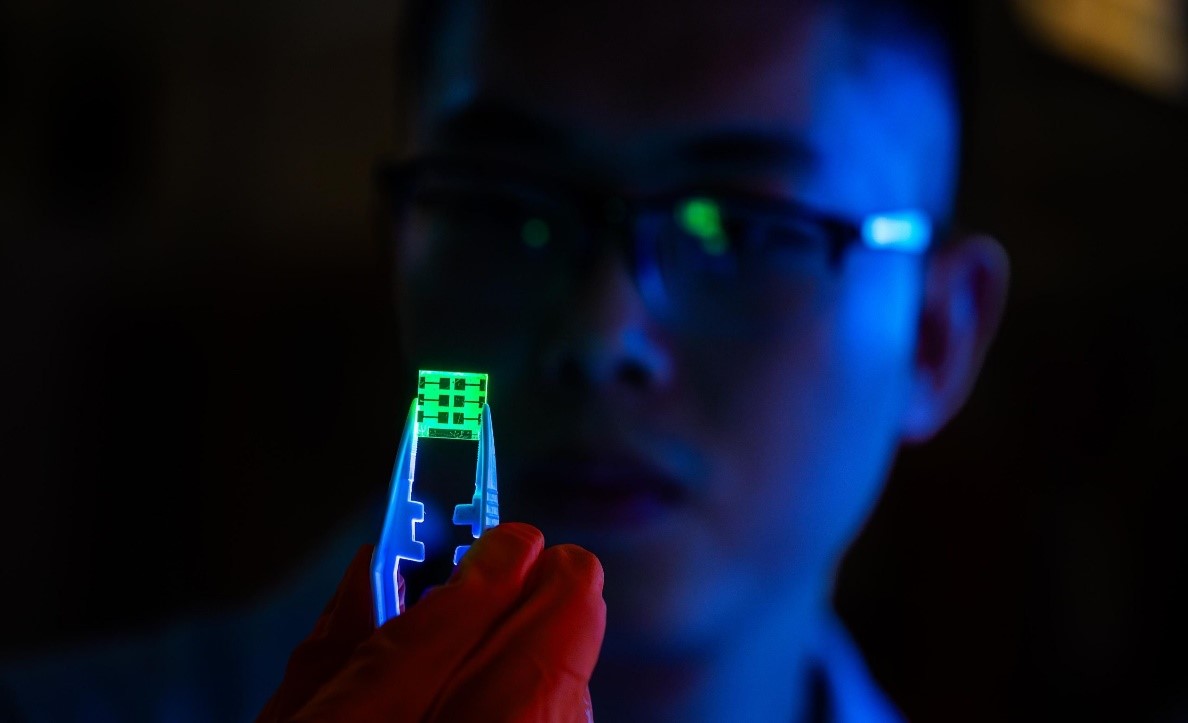

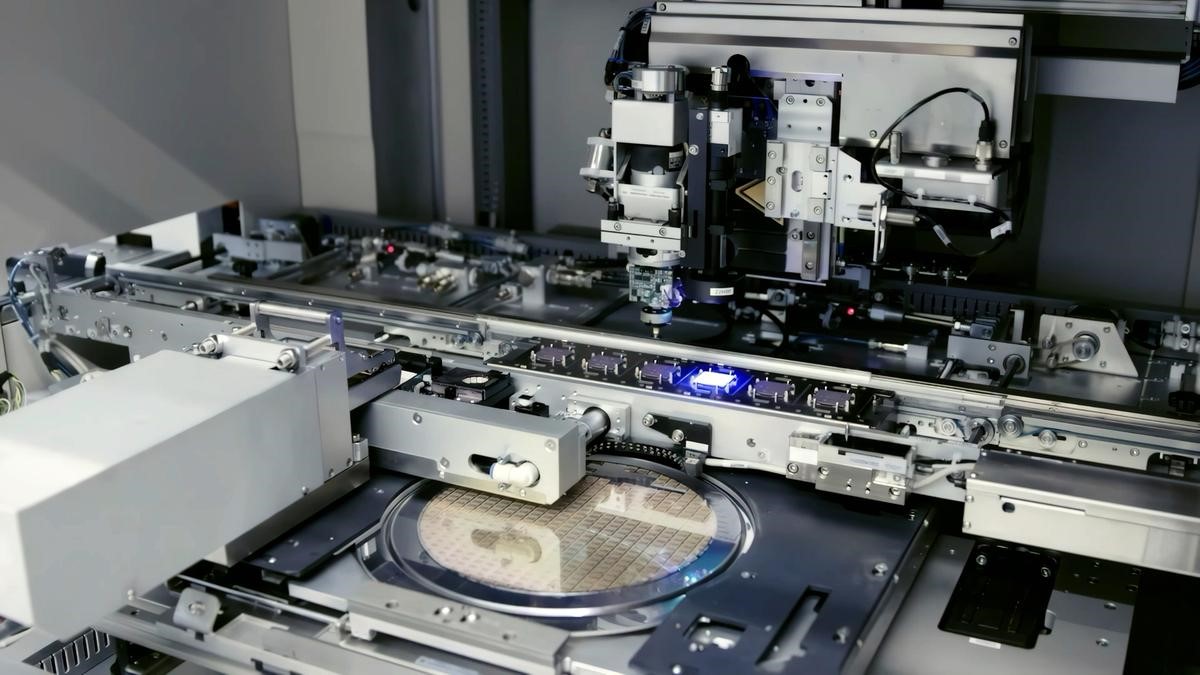

Figure 1.semiconductor manufacturing machine.

A Potential Alternative to Gas Lasers

Smaller laser wavelengths allow for finer and more precise etching, making the 193 nm wavelength essential for manufacturing high-performance semiconductor chips. This is why major lithography equipment manufacturers like ASML, Canon, and Nikon incorporate this wavelength into their machines [1]. Figure 1 shows semiconductor manufacturing machine.

Traditional lithography machines utilize a sealed laser chamber filled with a mixture of Argon (Ar), Fluorine (F), and Neon (Ne) gases. When a high-voltage pulse excites these gases, it briefly forms an Argon Fluoride (ArF) excimer, which rapidly returns to its stable state, emitting a 193 nm UV photon.

These gas-based lasers are widely used due to their reliability, delivering pulses of around 100–120 Watts at frequencies of 8–9 kHz. However, they require precise handling of hazardous gases like fluorine, making them complex and costly to operate.

In contrast, the newly developed CAS laser is a fully solid-state system that eliminates the need for gas, relying solely on crystals and optical components. The researchers achieved this breakthrough using a Yb:YAG crystal amplifier to generate an initial infrared laser beam at 1030 nm.

This beam is then split using nonlinear optics, producing a 258 nm beam through Fourth-Harmonic Generation (FHG). Meanwhile, another portion of the 1030 nm beam is converted to a different wavelength (1553 nm) using an optical parametric amplifier (OPA). These two wavelengths are subsequently combined using cascaded Lithium Triborate (LBO) crystals, generating a coherent 193 nm laser beam.

A Long Road to Mass Production

Solid-state laser technology offers several advantages, including reduced use of toxic chemicals, elimination of fluorine gas, safer operation, simplified maintenance, and potentially lower operational costs. Additionally, solid-state lasers tend to be more compact and reliable than their gas-based counterparts.

However, significant challenges remain. The current CAS laser produces only 70 mW of power—several hundred times weaker than the 100–120-Watt output of commercial excimer lasers [2]. At this stage, the technology is not yet viable for large-scale semiconductor production, requiring further refinement before it can compete with existing lithography systems.

References

- https://interestingengineering.com/innovation/china-solid-state-uv-laser-transform-chipmaking

- https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=14322&gad_source=1&gclid=EAIaIQobChMIgeeEzdSijAMVZCaDAx1lEA-JEAAYASAAEgLol_D_BwE

Cite this article:

Keerthana S (2025), China's Revolutionary Solid-State Deep Ultraviolet Laser Could Redefine Chip Manufacturing, AnaTechMaz, pp. 146