Revolutionizing Stainless Steel for Hydrogen Production: HKU's 'Super Steel' Project Unveils SS-H2 Breakthrough

In a groundbreaking development, Professor Mingxin Huang and his team at the Department of Mechanical Engineering, University of Hong Kong (HKU), have achieved a significant milestone in stainless steel technology. This breakthrough, part of the 'Super Steel' Project, showcases the team's commitment to innovation, with notable achievements in anti-COVID-19 stainless steel in 2021 and ultra-strong Super Steel in 2017 and 2020.

Figure 1. Professor Mingxin Huang and Dr Kaiping Yu. (Credit: The University of Hong Kong)

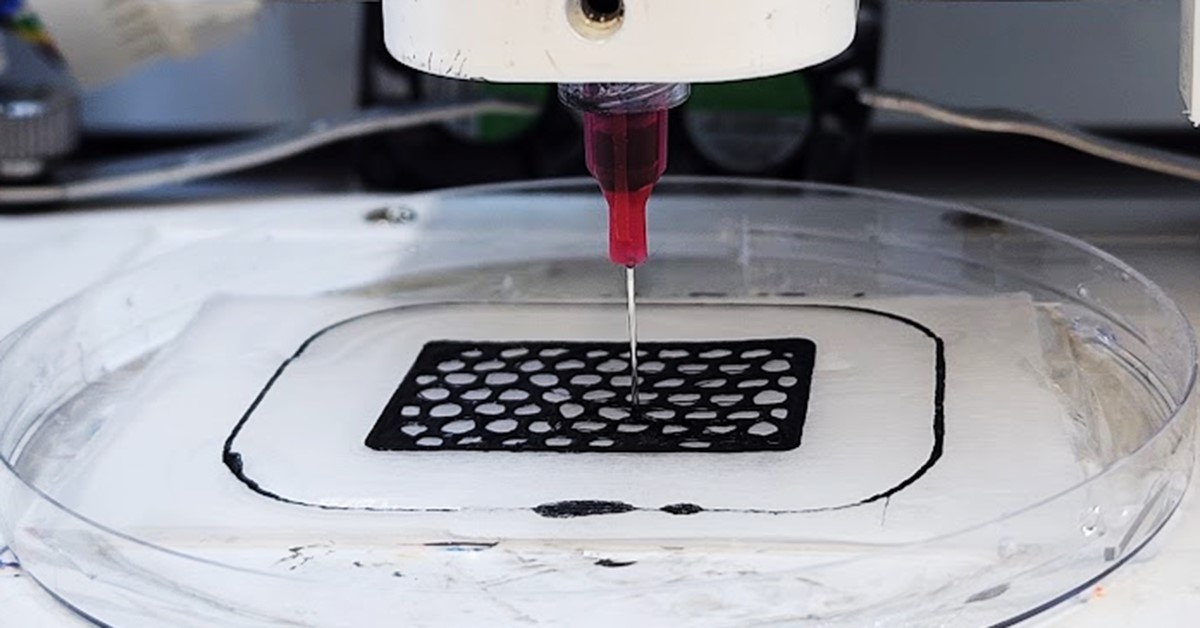

The New SS-H2: Revolutionizing Stainless Steel for Hydrogen Production

Figure 1 shows Professor Mingxin Huang and Dr Kaiping Yu. The recently unveiled stainless steel, known as SS-H2, boasts remarkable corrosion resistance, opening avenues for its application in green hydrogen production from seawater. This development is a critical step towards sustainable solutions in hydrogen production, particularly in environments where existing options are still evolving.

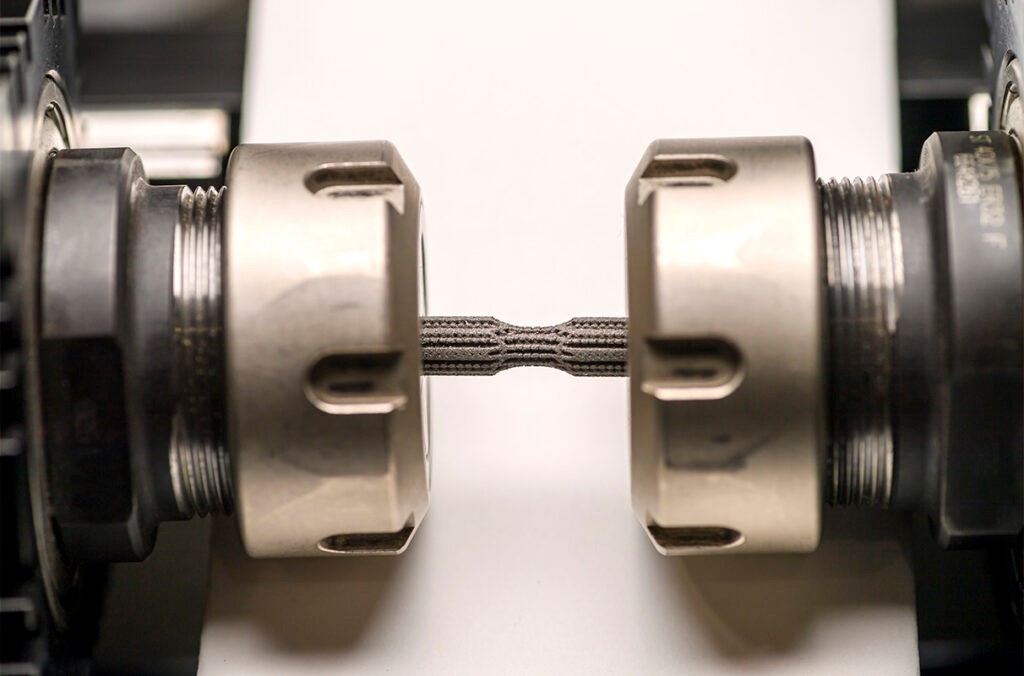

Comparative Performance and Cost-Efficiency

In saltwater electrolysis, SS-H2's performance is on par with current industrial practices utilizing Titanium for hydrogen production. However, the game-changer lies in its significantly lower cost compared to Titanium. This cost-effectiveness positions SS-H2 as a formidable contender in the realm of hydrogen production technology.

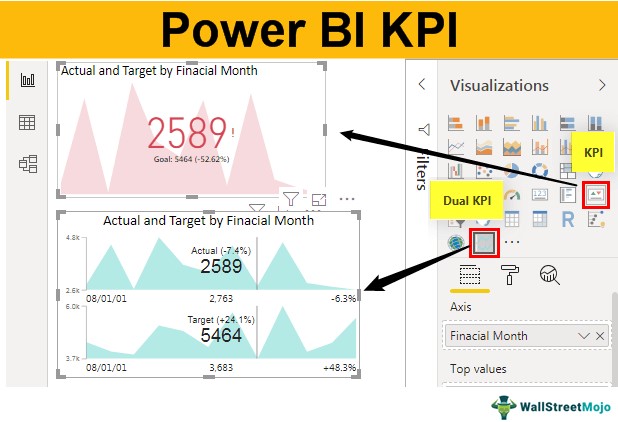

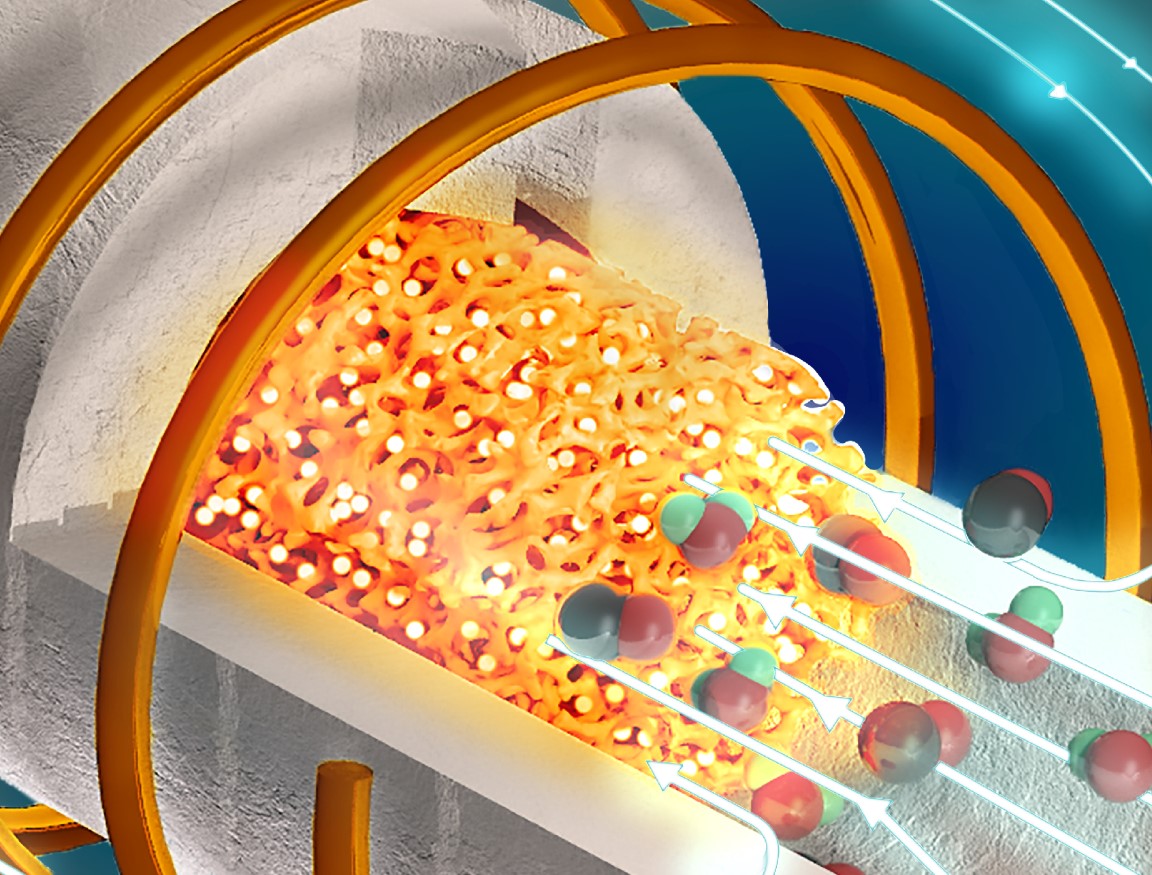

Scientific Breakthrough: The Sequential Dual-Passivation Strategy

The key to SS-H2's superior corrosion resistance lies in a "sequential dual-passivation" strategy devised by Professor Huang's team. Unlike conventional stainless steel, which relies on a single-passivation mechanism based on chromium (Cr), SS-H2 incorporates a secondary manganese (Mn)-based layer. This innovative approach prevents corrosion in chloride media, pushing SS-H2's resistance to an ultra-high potential of 1700 mV.

Challenging Conventions: Mn-Based Passivation

The discovery challenges conventional wisdom in corrosion science, as manganese (Mn) is typically considered to impair the corrosion resistance of stainless steel. The team's atomic-level results presented a counter-intuitive revelation, showcasing the potential of Mn-based passivation in stainless steel.

Path to Industrial Application

The journey from the initial discovery to scientific breakthrough took nearly six years of dedicated research. Professor Huang emphasizes the team's focus on developing high-potential-resistant alloys, overcoming fundamental limitations of conventional stainless steel. The SS-H2 breakthrough is not only exciting but also opens new possibilities for alloy development at high potentials.

Economic Implications and Industrial Applications

The economic implications of SS-H2 are substantial. Current water electrolysis systems often require expensive gold- or platinum-coated titanium for structural components. Professor Huang's team estimates that the use of SS-H2 could reduce the cost of structural materials by about 40 times. The team has already taken significant steps toward industrialization, producing tons of SS-H2-based wire in collaboration with a mainland factory.

The unveiling of SS-H2 marks a significant leap forward in stainless steel technology, with profound implications for the hydrogen production industry. Professor Huang's team's dedication to pushing the boundaries of material science has opened new doors for cost-effective, high-performance solutions in green hydrogen production. The future looks promising as the team progresses towards industrial applications, bringing us one step closer to a more sustainable and economically viable hydrogen production landscape.

Source: The University of Hong Kong

Cite this article:

Hana M (2023), Revolutionizing Stainless Steel for Hydrogen Production: HKU's 'Super Steel' Project Unveils SS-H2 Breakthrough, AnaTechMaz, pp. 56