AI-optimized manufacturing

Paper and pencil tracking, luck, significant global travel and opaque supply chains are part of today’s status quo, resulting in large amounts of wasted energy, materials and time. Accelerated in part by the long-term shutdown of international and regional travel by COVID-19, companies that design and build products will rapidly adopt cloud-based technologies to aggregate, intelligently transform, and contextually present product and process data from manufacturing lines throughout their supply chains. By 2025, this ubiquitous stream of data and the intelligent algorithms crunching it will enable manufacturing lines to continuously optimize towards higher levels of output and product quality – reducing overall waste in manufacturing by up to 50%. As a result, we will enjoy higher quality products, produced faster, at lower cost to our pocketbooks and the environment.[1]

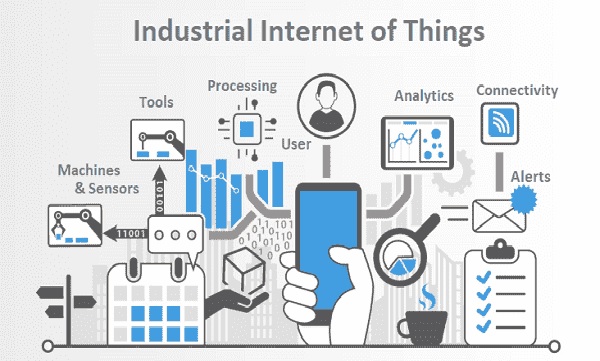

Figure. 1. AI-optimized manufacturing

AI in manufacturing is the intelligence of machines to perform humanlike tasks—responding to events internally and externally, even anticipating events—autonomously. The machines can detect a tool wearing out or something unexpected—maybe even something expected to happen—and they can react and work around the problem.[2]

Future Of AI Optimized Manufacturing

The continued enhancement in computer visualization has long been used for quality assurance by detecting product defects in real time. But now that manufacturing involves more information than ever integrated with the fact that plant managers do not want to pay employees to enter information—AI with computer vision can rationalize how information gets apprehended. A factory worker should be able to acquire raw materials reserve from the shelf and have the stock transaction created automatically based on a camera observing the process. This will be the natural user interface, just carrying out the task at hand not inputting or scanning things into a system. [3]

Benefits of AI Optimized Manufacturing

- detect production defects.

- validate the quality assurance.

- reduce downtime and costs.

- equip the machinery.

- enable workers to reach a high level of performance.[4]

References:

- https://www.weforum.org/agenda/2020/06/17-predictions-for-our-world-in-2025/

- https://redshift.autodesk.com/ai-in-manufacturing/

- https://www.plantautomation-technology.com/articles/the-future-of-artificial-intelligence-in-manufacturing-industries

- https://ai4manufacturing.com/benefits-of-ai-in-manufacturing/

Cite this article:

Sindhu C (2022), AI Optimized Manufacturing, AnaTechMaz, pp. 56