New 3D Printed Material can Sense their Own Movements

MIT researchers have created an approach for 3D printing products with tunable mechanical houses, that sense how they are transferring and interacting with the ecosystem. The scientists produce these sensing buildings using just a single material and a one run on a 3D printer.

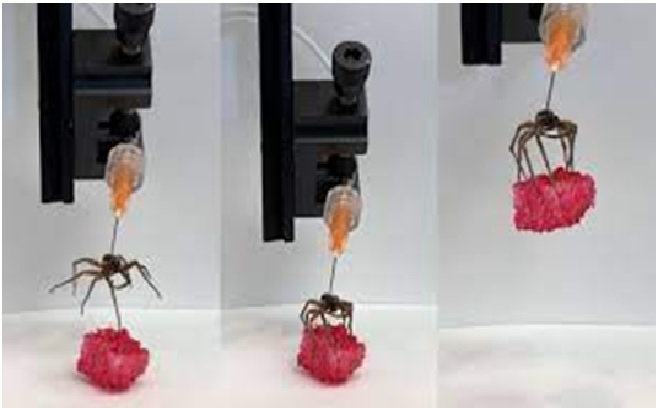

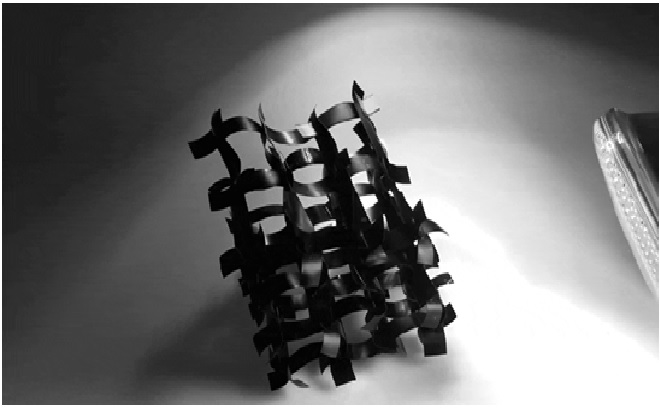

Figure 1: Sensing buildings with a single material and one run on a 3D printer.

Figure 1 shows thatthe scientists targeted their endeavors on lattices, a kind of “architected material,” which exhibits customizable mechanical qualities dependent entirely on its geometry. [1]

While architected materials can exhibit unique properties, integrating sensors within them is challenging given the materials’ often sparse, complex shapes. Placing sensors on the outside of the material is typically a simpler strategy than embedding sensors within the material.

The researchers used 3D printing to incorporate air-filled channels directly into the struts that form the lattice. When the structure is moved or squeezed, those channels deform and the volume of air inside changes.

The researchers can measure the corresponding change in pressure with an off-the-shelf pressure sensor, which gives feedback on how the material is deforming.Because they are incorporated into the material, these “fluidic sensors” offer advantages over conventional sensor materials.

The researchers incorporate channels into the structure using digital light processing 3D printing. In this method, the structure is drawn out of a pool of resin and hardened into a precise shape using projected light. An image is projected onto the wet resin and areas struck by the light are cured.

But as the process continues, the resin remains stuck inside the sensor channels. The researchers had to remove excess resin before it was cured, using a mix of pressurized air, vacuum, and intricate cleaning. [2]

They used this course of to create a number of lattice buildings and demonstrated how the air-filled channels generated clear suggestions when the buildings have been squeezed and bent.

Constructing off these outcomes, in addition they included sensors into a brand-new class of supplies developed for motorized smooth robots often known as handed shearing auxetics, or HSAs. HSAs could be twisted and stretched concurrently, which allows them for use as efficient smooth robotic actuators. However, they’re troublesome to “sensorize” due to their advanced varieties.

They 3D printed an HSA smooth robotic able to a number of actions, together with bending, twisting, and elongating. They ran the robotic by way of a sequence of actions for greater than 18 hours and used the sensor data to coach a neural community that would precisely predict the robotics movement. [3]

References:

- https://appsforpcfree.net/new-programmable-materials-can-sense-their-own-movements-mit-news/

- https://www.nanowerk.com/news2/gadget/newsid=61254.php

- https://dailyinformat.com/2022/08/10/new-programmable-materials-can-sense-their-own-movements/

Cite this article:

Sri Vasagi K (2022), New 3D Printed Material can Sense their Own Movements, AnaTechMaz, pp.163