Digital Twins

A digital twin is a digital representation of a physical object, process or service. A digital twin can be a digital replica of an object in the physical world, such as a jet engine or wind farms, or even larger items such as buildings or even whole cities. As well as physical assets, the digital twin technology can be used to replicate processes in order to collect data to predict how they will perform.

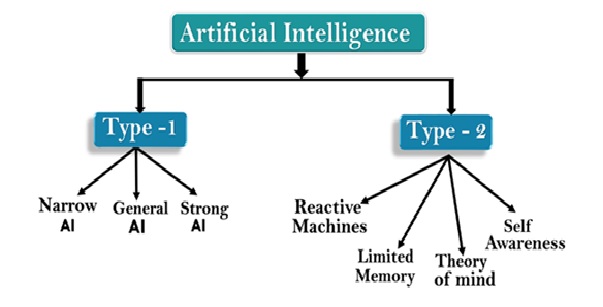

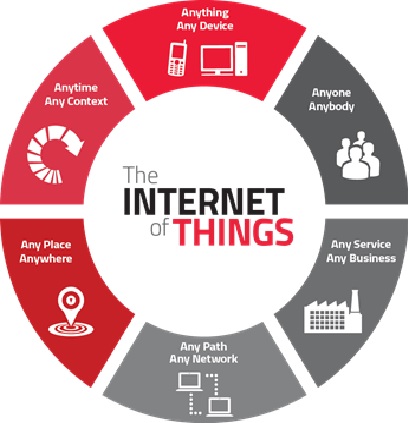

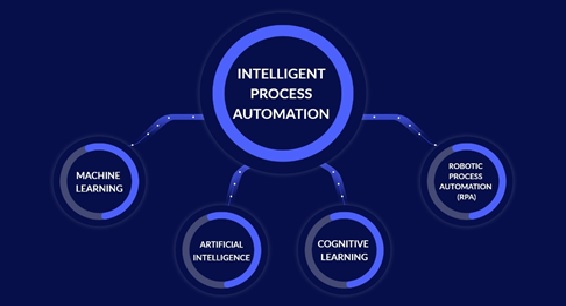

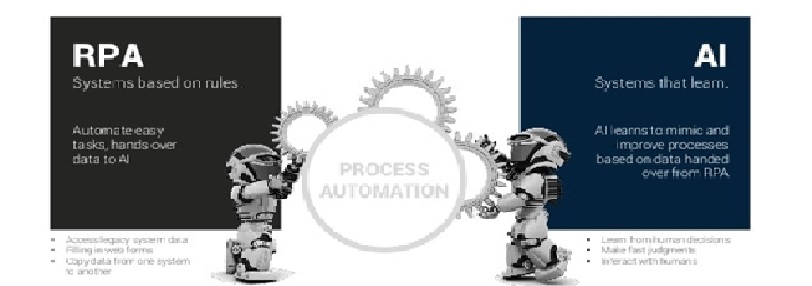

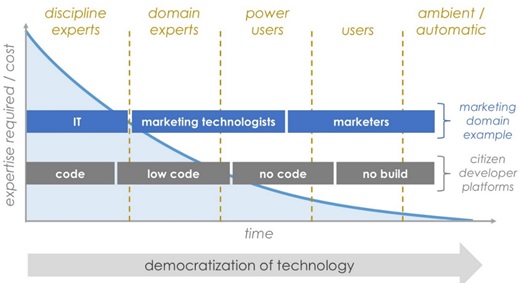

A digital twin is, in essence, a computer program that uses real world data to create simulations that can predict how a product or process will perform. [1] These programs can integrate the internet of things (Industry 4.0), artificial intelligence and software analytics to enhance the output. With the advancement of machine learning and factors such as big data, these virtual models have become a staple in modern engineering to drive innovation and improve performance.

In short, creating one can allow the enhancement of strategic technology trends, prevent costly failures in physical objects and also, by using advanced analytical, monitoring and predictive capabilities, test processes and services.

A digital twin is a virtual model designed to accurately reflect a physical object. The object being studied for example, a wind turbine is outfitted with various sensors related to vital areas of functionality. [2] These sensors produce data about different aspects of the physical object’s performance, such as energy output, temperature, weather conditions and more. This data is then relayed to a processing system and applied to the digital copy as shown in figure 1.

Once informed with such data, the virtual model can be used to run simulations, study performance issues and generate possible improvements, all with the goal of generating valuable insights which can then be applied back to the original physical object.

Figure 1: The Digital Twins

Advantages and benefits of digital twins

Better R & D

The use of digital twins enables more effective research and design of products, with an abundance of data created about likely performance outcomes. [3] That information can lead to insights that help companies make needed product refinements before starting production.

Greater efficiency

Even after a new product has gone into production, digital twins can help mirror and monitor production systems, with an eye to achieving and maintaining peak efficiency throughout the entire manufacturing process.

Product end-of-life

Digital twins can even help manufacturers decide what to do with products that reach the end of their product lifecycle and need to receive final processing, through recycling or other measures. By using digital twins, they can determine which product materials can be harvested.

Advantages and benefits of digital twins

A fundamental change to existing operating models is clearly happening. [4] A digital reinvention is occurring in asset-intensive industries that is changing operating models in a disruptive way, requiring an integrated physical plus digital view of assets, equipment, facilities and processes. Digital twins are a vital part of that realignment.

The future of digital twins is nearly limitless, due to the fact that increasing amounts of cognitive power are constantly being devoted to their use. So digital twins are constantly learning new skills and capabilities, which means they can continue to generate the insights needed to make products better and processes more efficient.

Learn how change will impact your industry in this article on transforming asset operations with digital twins.

References:

- https://www.ibm.com/topics/what-is-a-digital-twin

- https://www.twi-global.com/technical-knowledge/faqs/what-is-digital-twin

- https://www.networkworld.com/article/3280225/what-is-digital-twin-technology-and-why-it-matters.html

- https://www.section.io/engineering-education/introduction-to-digital-twin-technology/

Cite this article:

Vinotha D (2021), Digital Twins, AnaTechMaz, pp. 11