The Future of Innovative Ways Prefabricated Buildings

In the modern age, prefabrication is an umbrella term referring to the practice of assembling a variety of structural components at a manufacturing site and transporting those sub-assemblies to the construction jobsite upon completion. [1] It is most often used in reference to building and civil engineering, where prefabricated concrete and steel sections are repeated many times in the building plan.

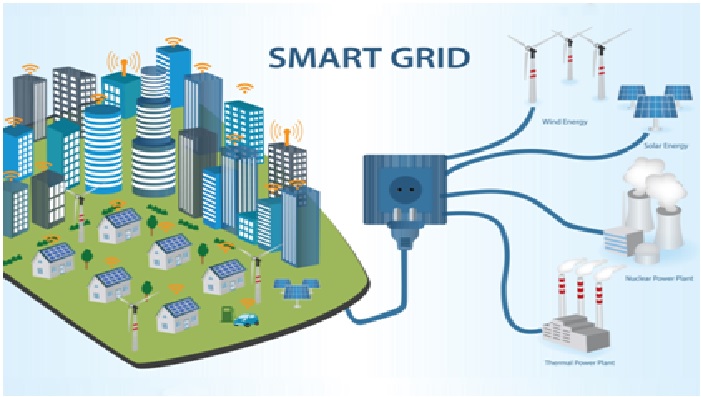

Figure 1. The Prefabricated Building [2]

Because that particular part or form is duplicated so often, it’s easier and more cost-effective to manufacture scores of them at once, rather than build them as needed on-site. Economies of scale dictate a lower cost per piece when made at a facility specifically designed to meet that need, not to mention bulk transportation that saves on travel costs. The increased construction productivity from preparing a structure fully then adding prefabbed pieces in large batches should not be discounted either. The process of prefabricated is shown in Figure 1.

The various components of prefabricated buildings are engineered at a factory and delivered to a location where they are assembled. Prefabricated buildings are a viable and reliable alternative for creating work space, storage area, and flexible manufacturing facilities. [3] The components of prefabricated buildings include framing, secondary supports, wall and roof panels, door and window frames, fasteners, and sheeting and insulation.

Although the larger components may seem to be the foundational and necessary parts of the assembly of prefabricated buildings, the most essential and crucial items are the screws, bolts, nails, and fasteners required to hold the various elements together. A wide selection of fasteners is carefully engineered and designed for long use and easy installation.

Components include construction elements such as windows, doors, and trusses, which by themselves are not complete panels. Among the prefabricated materials, these have the least amount of off-site assembly, but usage is more flexible since they can be placed and installed according to actual site conditions.

Prefabrication is just not used in the construction of huge buildings, [4] but it has several other uses too:

References:

- https://blog.plangrid.com/2019/11/everything-need-know-prefabrication/

- https://www.build-review.com/innovative-ways-prefabricated-buildings-are-used-today/

- https://www.iqsdirectory.com/articles/modular-building/prefabricated-building.html

- https://gosmartbricks.com/prefabricated-construction/

Cite this article:

Vinotha D (2022), The Future of Innovative Ways Prefabricated Buildings, AnaTechMaz, pp.110