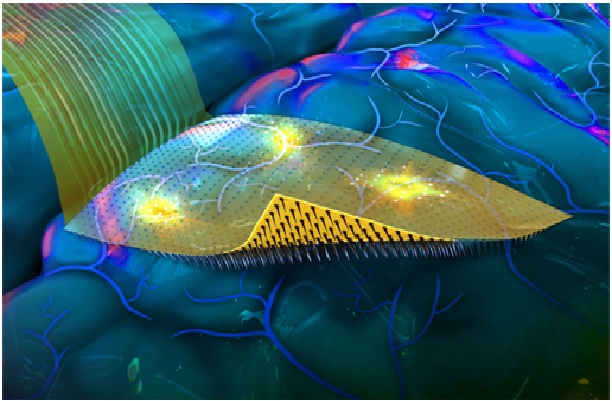

A new brain-computer interface with a flexible backing

Engineering researchers have invented an advanced brain-computer interface with a flexible and moldable backing and penetrating microneedles. Adding a flexible backing to this kind of brain-computer interface allows the device to more evenly conform to the brain's complex curved surface and to more uniformly distribute the microneedles that pierce the cortex. The microneedles, which are 10 times thinner than the human hair, protrude from the flexible backing, penetrate the surface of the brain tissue without piercing surface venules, and record signals from nearby nerve cells evenly across a wide area of the cortex. [1]

Figure 1. A new brain-computer interface with a flexible backing

Figure 1 shows this new brain-computer interface is on par with and outperforms the “Utah Array,” which is the existing gold standard for brain-computer interfaces with penetrating microneedles. The Utah Array has been demonstrated to help stroke victims and people with spinal cord injury. People with implanted Utah Arrays are able to use their thoughts to control robotic limbs and other devices in order to restore some everyday activities such as moving objects. [2]

Thinner and transparent backings

These soft-backed brain-computer interfaces are thinner and lighter than the traditional, glass backings of these kinds of brain-computer interfaces. The researchers note in their Advanced Functional Materials paper that light, flexible backings may reduce irritation of the brain tissue that contacts the arrays of sensors. The flexible backings are also transparent. In the new paper, the researchers demonstrate that this transparency can be leveraged to perform fundamental neuroscience research involving animal models that would not be possible otherwise. The team, for example, demonstrated simultaneous electrical recording from arrays of penetrating micro-needles as well as optogenetic photostimulation. [3]

Two-sided lithographic manufacturing

The flexibility, larger microneedle array footprints, reconfigurability and transparency of the backings of the new brain sensors are all thanks to the double-sided lithography approach the researchers used.

Conceptually, starting from a rigid silicon wafer, the team’s manufacturing process allows them to build microscopic circuits and devices on both sides of the rigid silicon wafer. On one side, a flexible, transparent film is added on top of the silicon wafer.[4]

References:

- https://www.sciencedaily.com/releases/2022/03/220315165029.htm

- https://www.nanowerk.com/nanotechnology-news2/newsid=60106.php

- https://digitallatestnews.in/a-new-brain-computer-interface-with-a-flexible-backing/

- https://ucsdnews.ucsd.edu/pressrelease/a-new-brain-computer-interface-with-a-flexible-backing

Cite this article:

Thanusri swetha J (2022), A new brain-computer interface with a flexible backing, AnaTechMaz, pp. 95