Overview of MEMS (Micro Electro Mechanical System)

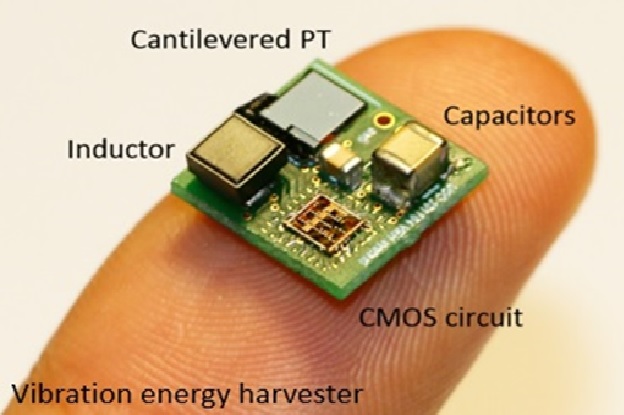

A MEMS (micro-electromechanical system) is a miniature machine that has both mechanical and electronic components. The physical dimension of a MEMS can range from several millimeters to less than one micrometer, a dimension many times smaller than the width of a human hair.

The label MEMS is used to describe both a category of micromechatronic devices and the processes used when manufacturing them. Some MEMS do not even have mechanical parts, yet they are classified as MEMS because they miniaturize structures used in conventional machinery, such as springs, channels, cavities, holes and membranes. [1]

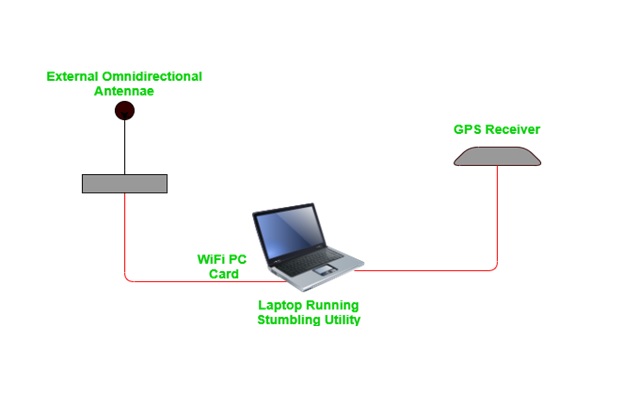

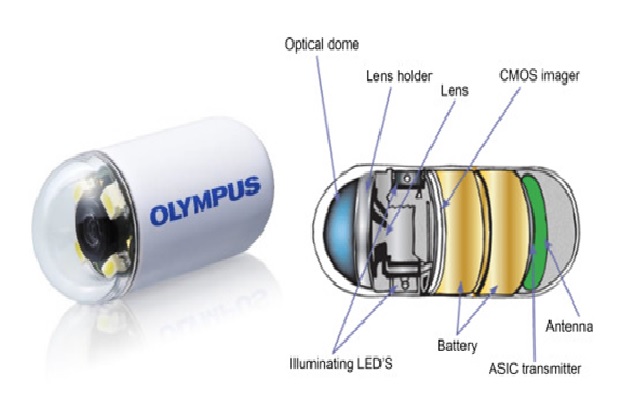

Figure 1. Overview of MEMS (Micro Electro Mechanical System)

Figure 1 shows micro-Electro-Mechanical Systems, or MEMS, is a technology that in its most general form can be defined as miniaturized mechanical and electro-mechanical elements (i.e., devices and structures) that are made using the techniques of microfabrication. The critical physical dimensions of MEMS devices can vary from well below one micron on the lower end of the dimensional spectrum, all the way to several millimeters. Likewise, the types of MEMS devices can vary from relatively simple structures having no moving elements, to extremely complex electromechanical systems with multiple moving elements under the control of integrated microelectronics. [2]

Advantages of MEMS

- Extremely scalable in manufacturing, resulting in very low unit costs when mass produced

- MEMS sensors possess extremely high sensitivity

- MEMS switches and actuators can attain very high frequencies

- MEMS devices require very low power consumption

- MEMS can be readily integrated with microelectronics to achieve embedded mechatronic systems

- Scaling effects at microscopic levels can be leveraged to achieve designs and dynamic mechanisms otherwise not possible at macro-scales

Disadvantages of MEMS

- Very expensive during the research and development stage for any new MEMS design or devices

- Very expensive upfront setup cost for fabrication cleanrooms and foundry facilities

- Fabrication and assembly unit costs can be very high for low quantities. Therefore, MEMS are not suitable for niche applications, unless cost is not an issue

- Testing equipment to characterise the quality and performance can also be expensive [3]

References:

- https://internetofthingsagenda.techtarget.com/definition/micro-electromechanical-systems-MEMS

- https://www.mems-exchange.org/MEMS/what-is.html

- https://engineeringproductdesign.com/mems-micro-electro-mechanical-system/

Cite this article:

Thanusri swetha J (2021), Overview of MEMS (Micro Electro Mechanical System), Anatechmaz, pp. 56