Researchers Achieve 3D Printing of a Single Complex Structure with Two Metals, Moving Beyond Welding

A research team at Penn State has developed a novel 3D-printing technique to create a complex metal structure by seamlessly fusing two different metals—an achievement previously only possible through welding.

Utilizing an advanced additive manufacturing technique called multi-material laser powder bed fusion—made possible by a newly acquired system at Penn State's Center for Innovative Materials Processing Through Direct Digital Deposition (CIMP-3D)—the team successfully 3D-printed a complex structure combining low-carbon stainless steel and bronze (90% copper, 10% tin). Their findings are published in npj Advanced Manufacturing.

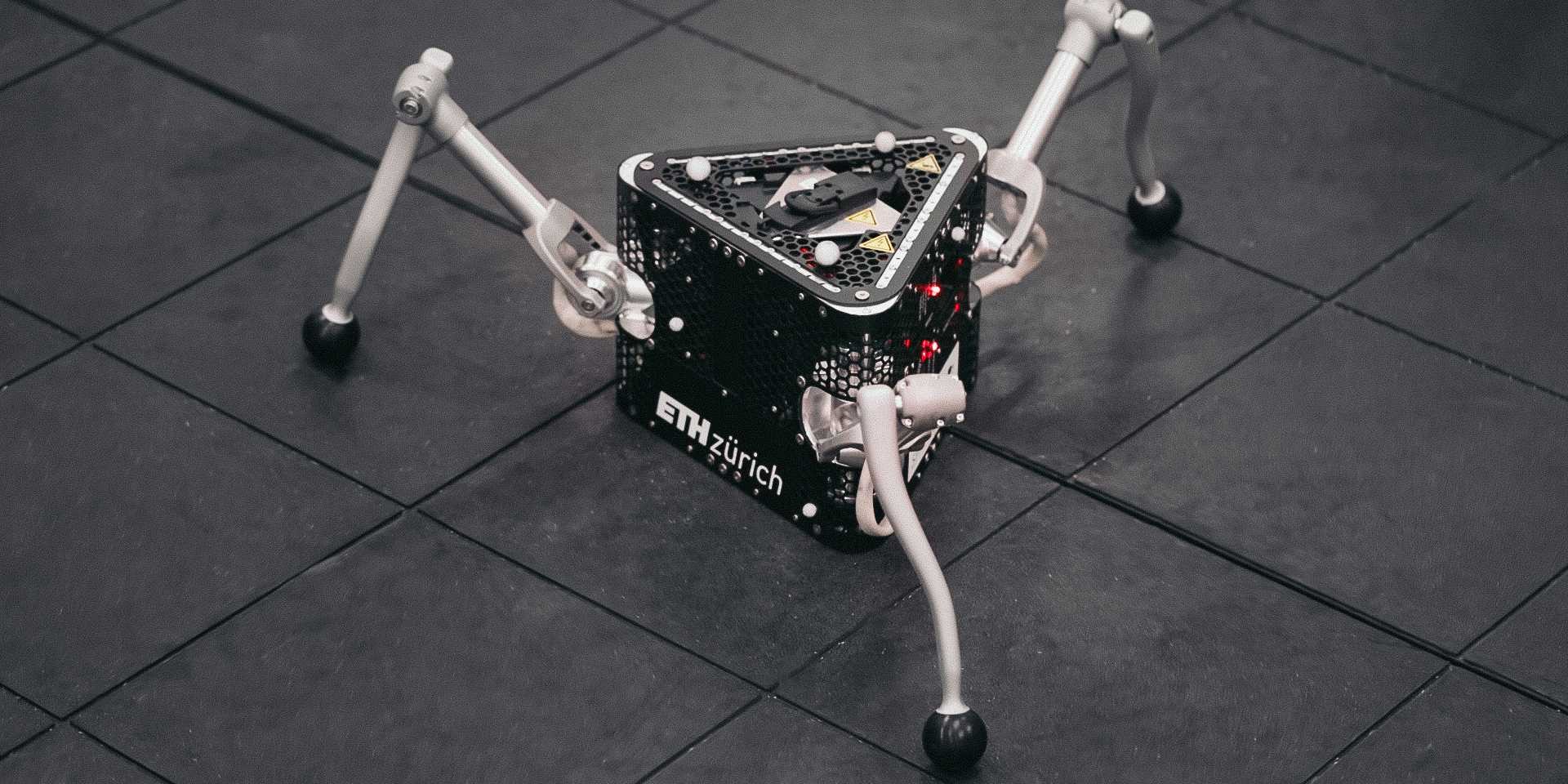

Figure 1. Micro-CT rendering of a multi-material gyroid beam made from stainless steel (blue) and bronze (orange) using the Aerosint system.

Jacklyn Griffis, a doctoral candidate in mechanical engineering and the paper's first author, explained, "Through a process called selective powder deposition, we can now melt multiple powdered metals within a single layer during additive manufacturing—making us the first university in the U.S. to achieve this [1]. The fine powders, similar in size to flour at tens of microns in diameter, can be selectively deposited with micron-level precision and then fused together using a laser." Figure 1 shows Micro-CT rendering of a multi-material gyroid beam made from stainless steel (blue) and bronze (orange) using the Aerosint system.

The researchers utilized an Aerosint selective powder deposition system, acquired by CIMP-3D in August 2023, to print and test the metal part. This system was integrated into an existing 3D Systems ProX320 AM machine in the Systems for Hybrid-Additive Process Engineering (SHAPE) Lab at CIMP-3D. According to Griffis, the one-centimeter-tall metal part consists of thousands of layers of metal powder and requires a few hours to print.

"We now have the technology to process and print multi-material metal parts while also monitoring the melt pool in real time to detect and address potential issues," said Guha Manogharan, corresponding author, associate professor of mechanical engineering, head of the SHAPE Lab, and co-director of CIMP-3D. "By generating a digital 3D rendering of the part using CT scans, we can identify pores, interface cracks, or micron-scale defects."

By simultaneously printing two metals within a single powder layer, researchers navigated complex challenges related to processing conditions and part quality. This study specifically examined how build orientation—whether printed upright, flat, or on its side—affects the final structure.

"In our analysis, we linked the part’s build orientation to various structural observations, including defects such as cracking and porosity, interfacial microstructures, and how elements diffuse or blend across the interface," said Griffis. "We then correlated these printed defects with the part’s overall performance."

The researchers' final structure is a gyroid—a complex shape commonly used in applications like heat exchangers and biomedical implants. They selected this design to showcase the capabilities of their new manufacturing process, as only multi-material laser powder bed fusion can produce a multi-material gyroid.

"Penn State has long been a leader in metal additive manufacturing, but now we can fabricate complex multi-material parts, not only creating intricate designs but also precisely controlling material placement," said Manogharan. "To achieve full-scale production, we need to understand the causes of defects related to materials and manufacturing conditions, particularly why parts fail at the interfaces."

In future studies, the researchers aim to enhance the 3D-printing process by implementing an in-process monitoring system, making it more robust and production-ready [2]. They also plan to expand their work by incorporating additional metal alloys, such as Inconel and copper, into multi-material laser powder bed fusion.

References:

- https://techxplore.com/news/2025-04-welding-3d-complex-metals.html

- https://www.psu.edu/news/engineering/story/beyond-welding-researchers-3d-print-two-metals-single-complex-structure

Cite this article:

Janani R (2025), Researchers Achieve 3D Printing of a Single Complex Structure with Two Metals, Moving Beyond Welding, AnaTechMaz, pp. 178