Milestone In Space Manufacturing: 8km Of Fiber Optics Produced on the ISS

A collaboration between a Silicon Valley start-up and researchers from Adelaide University has ventured into space manufacturing in an effort to enhance optical fiber capabilities, resulting in immediate success.

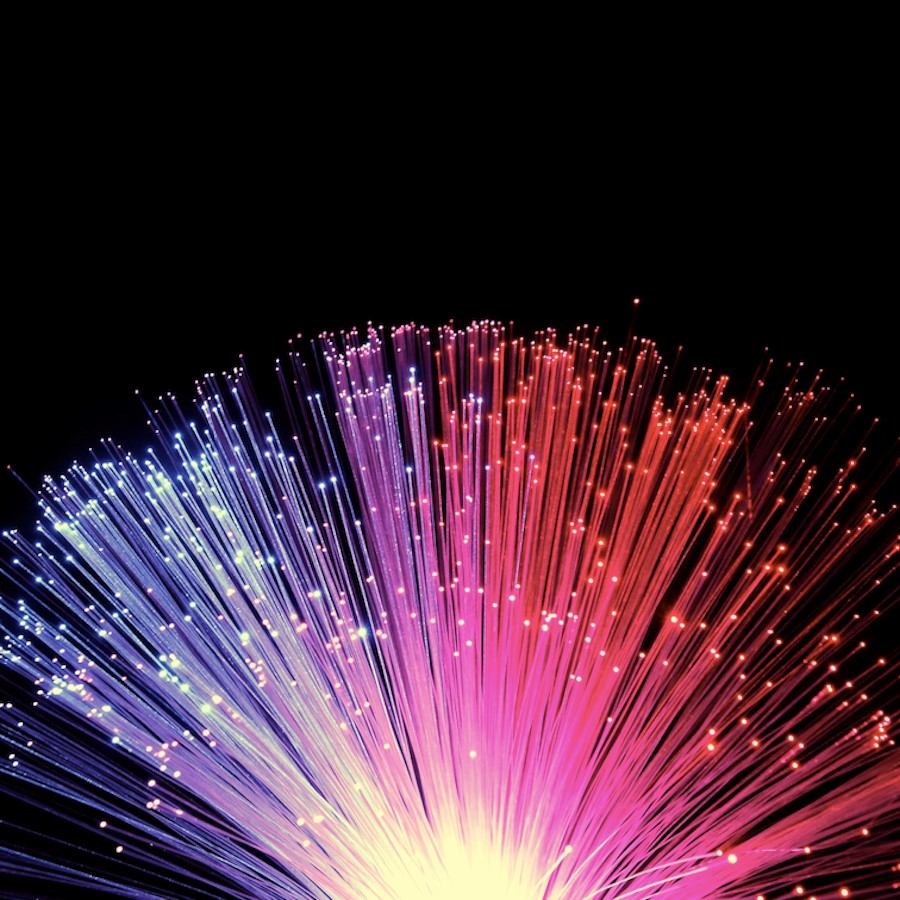

Optical fiber communication involves the conversion of electrical signals into pulses of light transmitted through a cable, typically made of thin silica or glass. Reverting the pulse to an electrical signal yields usable data. Optical cables utilize internal reflection to maximize signal transmission over long distances, surpassing the capabilities of copper wires. They serve as the foundation of global internet infrastructure, telecommunication networks, and various other applications.

Figure 1. Achievement in Space Manufacturing: 8km of Fiber Optics Manufactured on the ISS

Figure 1 Show in Achievement in Space Manufacturing: 8km of Fiber Optics Manufactured on the ISS Manufacturing high-quality fiber optic cable on Earth poses challenges due to gravity. The current manufacturing process utilizes a draw tower, where molten glass is allowed to descend towards the ground under the influence of gravity. As the molten glass descends, it gradually narrows to achieve its intended diameter.

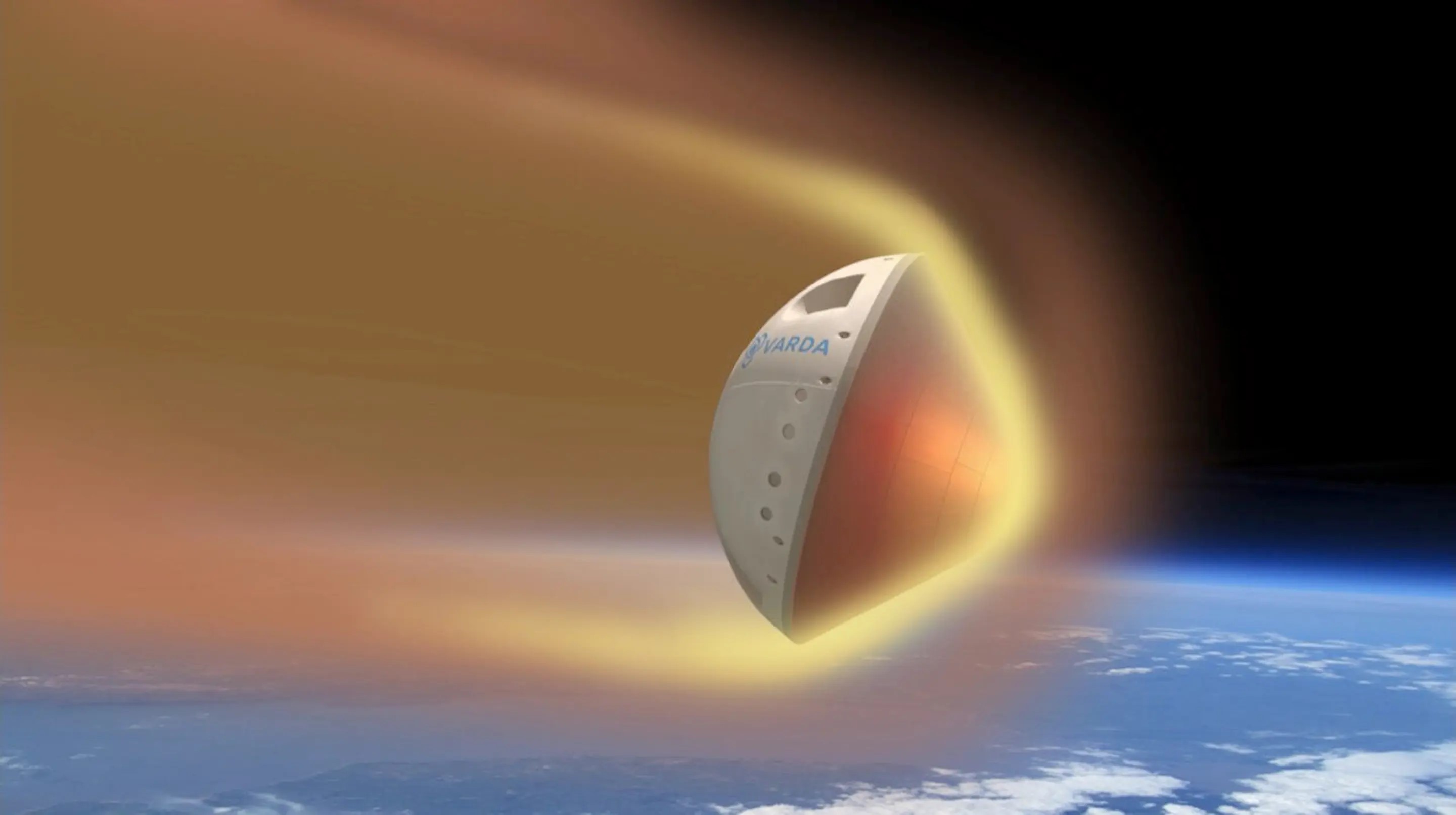

To address the challenges posed by gravity, the Optofab team from The University of Adelaide's Institute for Photonics and Advanced Sensing (IPAS) took a novel approach by sending glass rods into space. On January 31st, a SpaceX rocket delivered the glass rods and a fiber production device into orbit, where they were installed on the ISS.

The outcome was remarkable: within just two weeks of operation, the system generated over 8km of continuous optical fiber. This production rate represents a significant advancement compared to current capabilities on Earth.

ZBLAN glass was chosen for its exceptional performance compared to commercial-grade silica. It boasts a wider transmission range, enabling signals to travel longer distances before experiencing attenuation, and offers greater bandwidth along the fiber, facilitating the transmission of more data in less time. This capability to transfer more data over extended distances reduces the necessity for power amplification when sending signals across the globe.

The Outlook for Space Manufacturing

Professor Heike Ebendorff-Heidepriem highlights two obstacles that must be addressed for a ZBLAN fiber to realize its full potential. Firstly, gravity induces crystallization of ZBLAN during the drawing process. Secondly, the glass's purity must be increased significantly, by a factor of 1000, to unlock its maximum capabilities.

While Professor Ebendorff-Heidepriem and her team are currently focusing on overcoming the purity challenge, addressing the gravitational issue required external assistance. Flawless Photonics, a space fiber optic start-up, has pioneered a fiber drawing device capable of extruding ZBLAN glass in space, leveraging the microgravity of planetary orbit to create the fiber.

The design of the optical fiber drawing device used in space for fiber production is a crucial aspect of this innovation. Once produced, the optical fiber will be returned to Earth for analysis by the IPAS team. They will meticulously examine, characterize, and assess the optical properties of this space-manufactured fiber to validate or refute its theoretical superiority over earth-made counterparts.

Source:COSMOS

Cite this article:

Janani R (2024), Milestone in Space Manufacturing: 8km Of Fiber Optics Produced on the ISS, AnaTechMaz, pp.15