Varda: Unleashing the Future of Space Manufacturing and Hypersonic Testing in One Bold Satellite Deployment

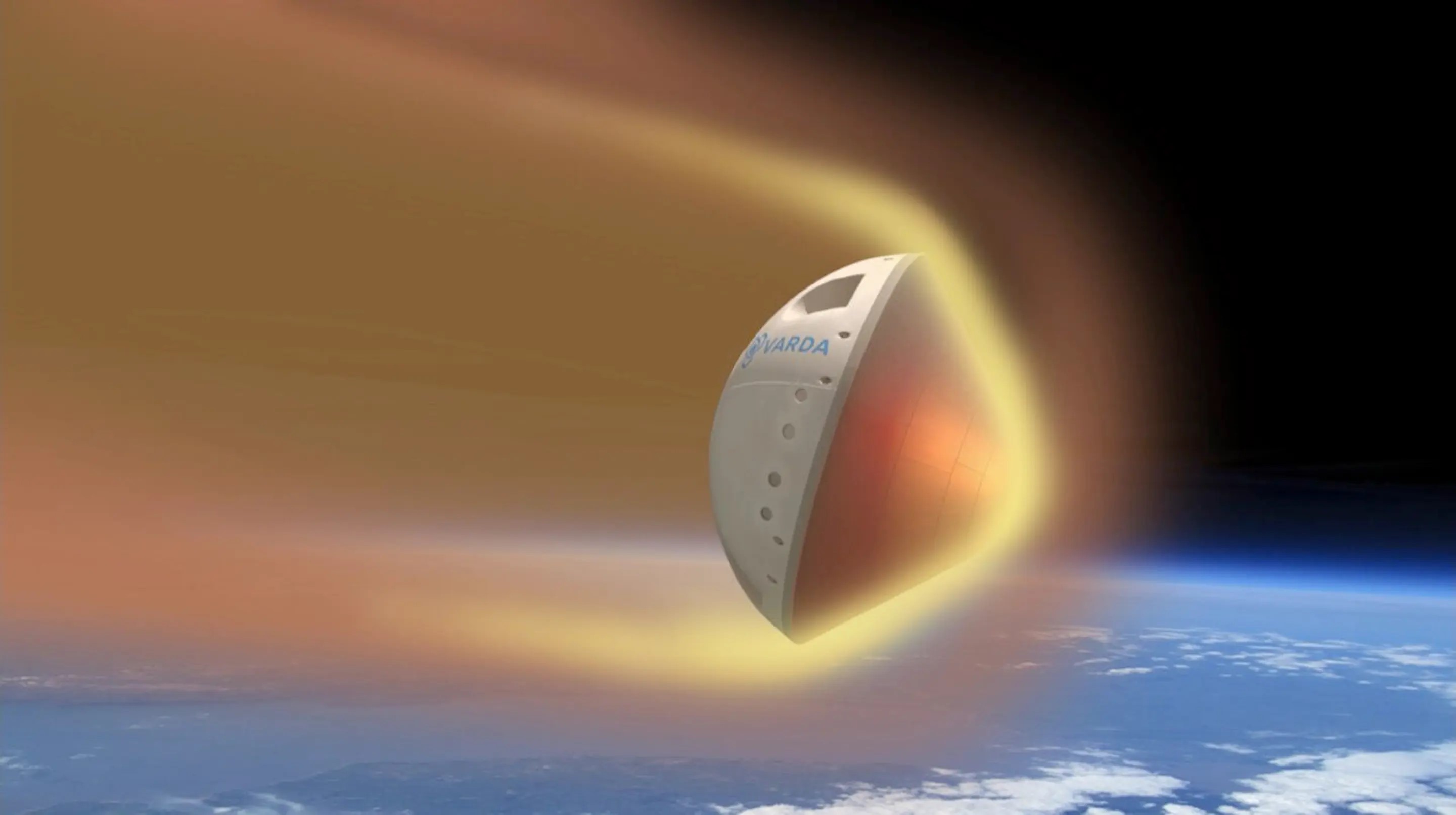

California-based startup Varda Space Industries, co-founded by a former SpaceX veteran, recently achieved a significant milestone by successfully deploying its inaugural satellite, W-Series 1, into orbit. Varda's primary objective is to revolutionize space manufacturing by initiating large-scale production of materials that are either impossible to manufacture on Earth or can be developed more efficiently and with superior quality in the microgravity environment. [1]

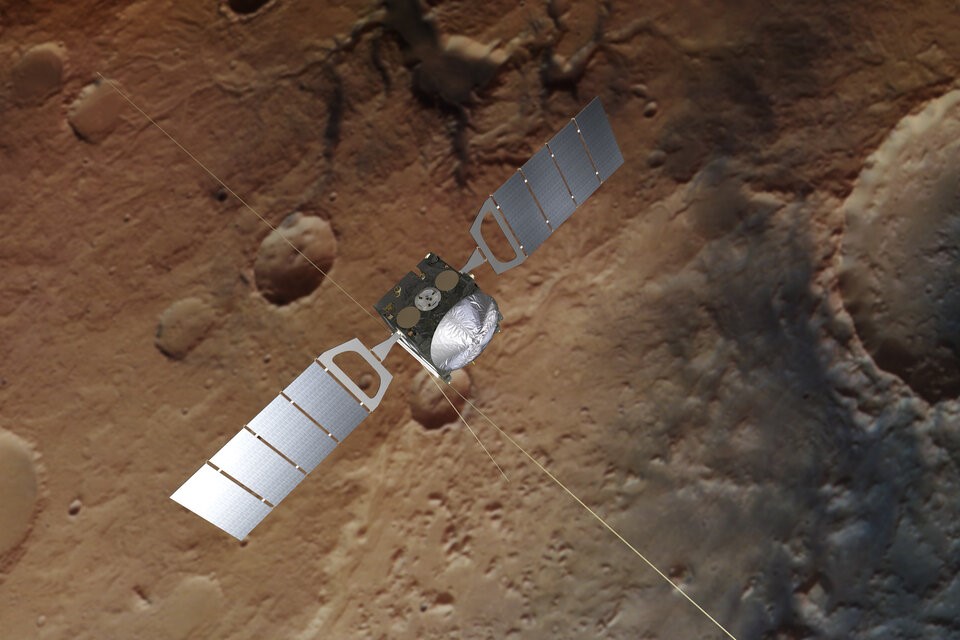

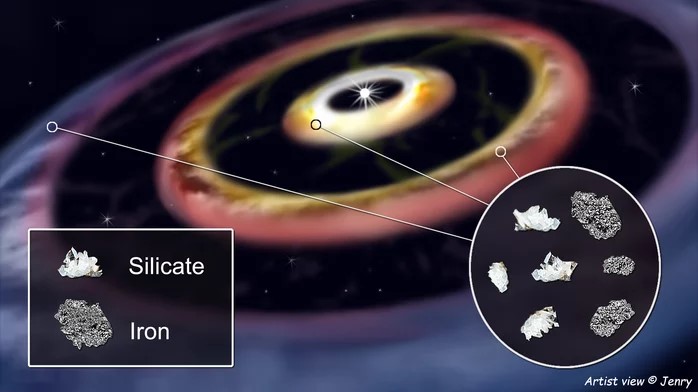

Figure 1. Varda Space.

Figure 1 shows Varda Space. In an exciting update shared on Twitter, Varda announced, "The world's first space factory's solar panels have discovered the sun, and the satellite is now commencing the de-tumbling process." This achievement came shortly after SpaceX's Transporter-8 mission lifted the satellite into orbit on Monday, June 13th. [1]

The allure of manufacturing in space stems from the unique advantages offered by the absence of gravity or the microgravity conditions experienced in orbit. In Earth-based laboratories, gravity acts as a constant force that influences various physical processes. However, in the microgravity environment of space, these dynamics are altered significantly. [2]

For instance, the absence of gravity eliminates convection currents, as there is no "up" direction for heat to rise towards. Additionally, particles in liquids do not clump together and rise or sink as they do on Earth. These altered conditions create exciting possibilities for manufacturing. [2]

According to Varda's pamphlet, these changes enable the creation of tunable particle size distributions, more orderly crystal formations, and novel structures. These advancements have the potential to enhance bioavailability of drugs, extend the shelf-life of products, generate new intellectual property, and open up innovative routes of administration. [2]

The microgravity environment of space, especially for protein crystal growth, has emerged as a highly advantageous realm for research and development. NASA recognizes protein crystal growth as the largest category of experiments conducted on the International Space Station (ISS). [2]

For drug developers, this environment offers a compelling opportunity to crystallize biological proteins and study their structures with precision. This knowledge enables the design of medications that can effectively bind to these proteins. Moreover, microgravity labs in space can be utilized to manufacture drugs in highly precise crystalline forms. [2]

Although not referring to complete tablets with inexpensive additives, the active ingredients used in these drugs can be incredibly valuable per kilogram. This unique manufacturing approach in space presents potential cost and quality advantages for drug development. [2]

Varda Space Industries has ambitious plans for the future, including the development of reusable space factory modules. Additionally, the company is exploring the concept of a manufacturing station that remains in orbit permanently. This station would serve as a hub for transporting materials, equipment, and maintenance gear as needed. While these endeavors are considered part of the medium-term future, they signify the official commencement of the space factory era. Varda is at the forefront of ushering in a new age of manufacturing in space. [2]

Reference:

- https://interestingengineering.com/innovation/worlds-first-space-factory-successfully-deployed

- https://newatlas.com/space/worlds-first-space-factory-varda/

Cite this article:

Hana M (2023), Varda: Unleashing the Future of Space Manufacturing and Hypersonic Testing in One Bold Satellite Deployment, AnaTechMaz, pp. 4