Supersonic Speed Threshold for Strong Metal Bonding Discovered

Cornell research reveals that tiny metal particles achieve the strongest bonds at an optimal supersonic speed, challenging the assumption that faster is always better in high-speed materials science.

In industrial processes like cold spray coating and additive manufacturing, tiny metal particles collide at extreme speeds to form strong metallic bonds. These high-energy impacts create durable layers, enhancing material performance. Understanding the bonding mechanisms can improve manufacturing techniques and lead to stronger, more reliable materials.

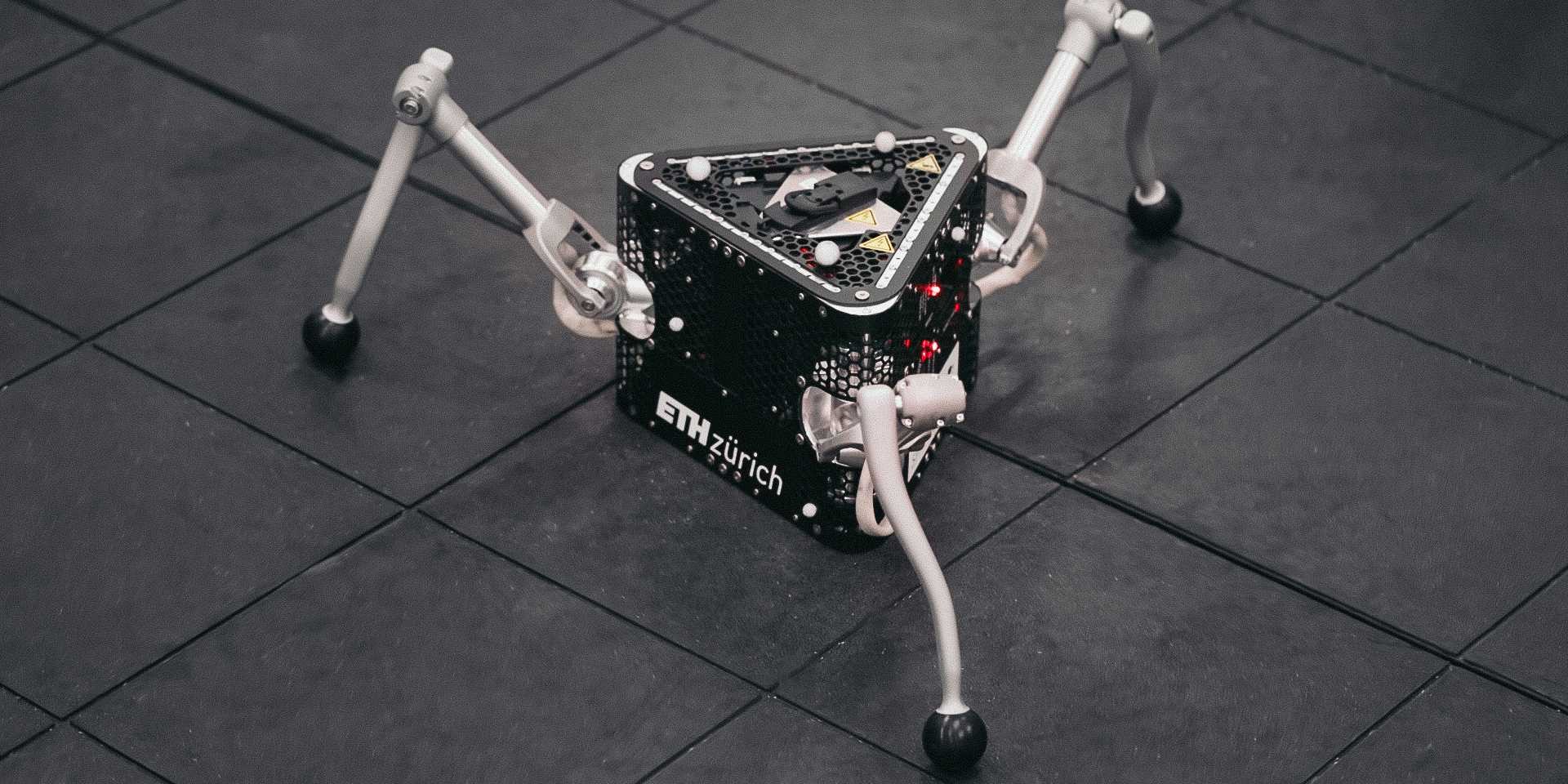

Figure 1. Researchers study supersonic metal bonding with laser-driven microprojectiles

In a study published on March 31 in Proceedings of the National Academy of Sciences, Cornell scientists accelerated 20-micrometer aluminum particles to speeds of up to 1,337 meters per second—surpassing the speed of sound—and captured the impacts using high-speed cameras [1]. Figure 1 shows Researchers study supersonic metal bonding with laser-driven microprojectiles.

The findings revealed that bond strength improved with increasing impact velocity but started to decline beyond 1,060 meters per second. At 1,337 meters per second, the particles barely adhered to the surface.

Senior author Mostafa Hassani, an assistant professor at Cornell Engineering, described the findings as "a total surprise."

Hassani noted that while higher impact speeds were expected to improve bond quality, the study revealed a peak bond strength, beyond which further increases in speed weakened the bonds.

The decline in bond strength is due to intensified elastic recovery, where the surface material stores more energy as elastic strain instead of deforming to absorb impact energy. This causes particles to rebound after impact, stretching and damaging the interface, ultimately weakening the bond.

In certain industrial processes, excessively high velocities can erode or even melt the surface, hindering proper bonding. Lead author Qi Tang noted that these findings offer valuable insights into erosion mechanisms, helping to optimize manufacturing techniques.

Tang explained that while industry experts previously speculated that erosion was due to fast-moving particles plowing through the surface or melting at the interface, the study reveals a different mechanism [2]. At extremely high velocities, increased rebounding can cause already bonded particles to detach, preventing material buildup.

Although the study focused on aluminum, the researchers believe the peak bonding velocity phenomenon applies to all metals and alloys. Future research will examine the impact of particle size and explore engineering strategies to optimize both particles and substrate surfaces for stronger bonds.

References:

- https://news.cornell.edu/stories/2025/03/supersonic-speed-limit-strong-metal-bonding-revealed

- https://techxplore.com/news/2025-04-supersonic-limit-strong-metal-bonding.html

Cite this article:

Janani R (2025), Supersonic Speed Threshold for Strong Metal Bonding Discovered, AnaTechMaz, pp. 177