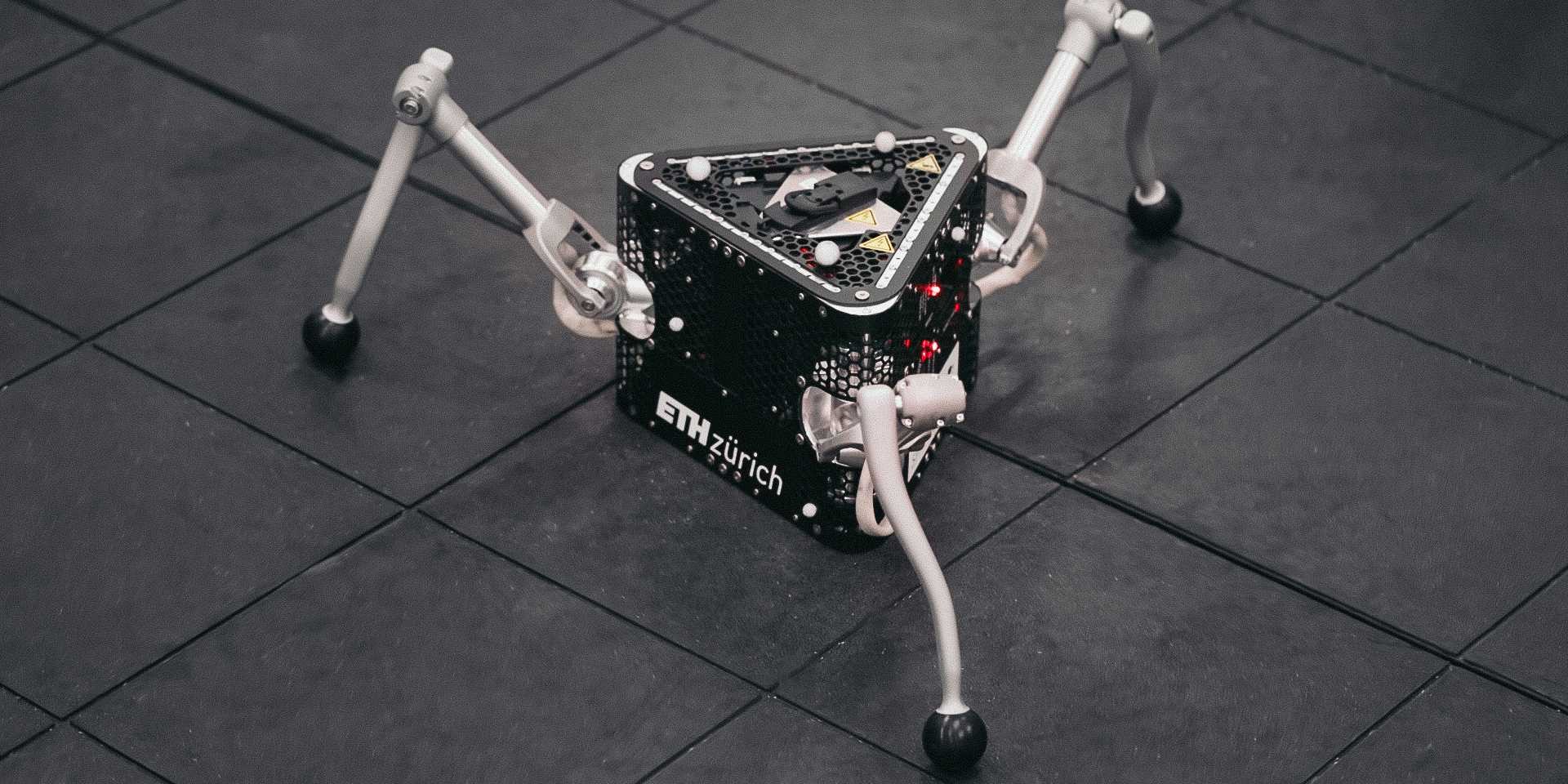

Nanostructured Copper Alloy Matches Superalloys in Strength and Stability

Scientists at the U.S. Army Research Laboratory and Lehigh University have engineered a nanostructured copper alloy with exceptional high-temperature performance, potentially transforming aerospace, defense, and industrial materials.

Researchers have introduced a Cu-Ta-Li (copper-tantalum-lithium) alloy with remarkable thermal stability and mechanical strength, making it one of the toughest copper-based materials ever developed. This breakthrough combines copper’s conductivity with superalloy-like durability, paving the way for advanced applications in hypersonics and high-performance turbine engines.

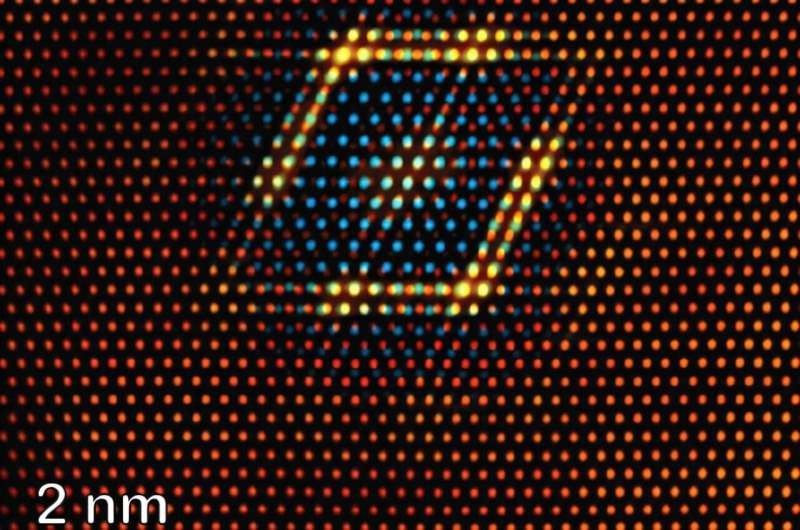

Figure 1.Colorized STEM image of Cu3Li precipitate in Cu-Ta-Li alloy

In collaboration with researchers from Arizona State University and Louisiana State University, the ARL and Lehigh scientists developed the alloy, which demonstrates the ability to endure extreme heat without significant deterioration [1]. Figure 1 shows Colorized STEM image of Cu3Li precipitate in Cu-Ta-Li alloy.

Integrating Copper with a Stability-Enhanced Nanostructure

The breakthrough lies in the formation of Cu3Li precipitates, stabilized by a Ta-rich atomic bilayer complexion, a concept developed by Lehigh researchers. Unlike typical grain boundaries that shift at high temperatures, this complexion stabilizes the structure, preventing grain growth and enhancing high-temperature performance. The alloy maintains its form under extreme thermal exposure and mechanical stress, resisting deformation even near its melting point, according to Patrick Cantwell, a research scientist at Lehigh University and co-author of the study.

By combining the high-temperature durability of nickel-based superalloys with copper's exceptional conductivity, this material opens the door to next-generation applications, such as heat exchangers, advanced propulsion systems, and thermal management solutions for advanced missile and hypersonic technologies.

A New Era of High-Performance Materials

The new Cu-Ta-Li alloy strikes a unique balance of properties that existing materials lack:

- Nickel-based superalloys, used in jet engines, are incredibly strong but lack copper's high thermal conductivity.

- Tungsten-based alloys are highly heat-resistant but are dense and challenging to manufacture.

- The Cu-Ta-Li alloy combines copper's excellent heat and electrical conductivity while maintaining strength and stability at extreme temperatures.

- Although it may not directly replace traditional superalloys in ultra-high temperature applications, it shows promise as a complementary material for next-generation engineering solutions.

The Process of Creating and Testing the Alloy

The team created the alloy using powder metallurgy and high-energy cryogenic milling to achieve a fine-scale nanostructure. They tested it through:

- 10,000 hours of annealing at 800°C to assess long-term stability.

- Advanced microscopy to reveal the Cu3Li precipitate structure.

- Creep resistance tests to confirm durability under extreme conditions.

- Computational modeling with density functional theory (DFT) to validate the Ta bilayer complexion's stabilizing role.

The U.S. Army Research Laboratory was granted a U.S. patent (US 11,975,385 B2) for the alloy, emphasizing its potential in defense applications such as military heat exchangers, propulsion systems, and hypersonic vehicles.

The researchers plan further studies to directly measure the alloy's thermal conductivity in comparison to nickel-based alternatives, prepare it for potential applications, and develop additional high-temperature alloys using a similar design approach.

"This project highlights how federal investment in fundamental science drives American leadership in materials technology," said Harmer [2]. "Discoveries like this are crucial for enhancing national security and fostering industrial innovation."

References:

- https://www.nature.com/articles/s41578-019-0121-4

- https://phys.org/news/2025-03-nanostructured-copper-alloy-rivals-superalloys.html

Cite this article:

Janani R (2025), Nanostructured Copper Alloy Matches Superalloys in Strength and Stability, AnaTechMaz, pp. 171