Supervisory Control and Data Acquisition (SCADA)

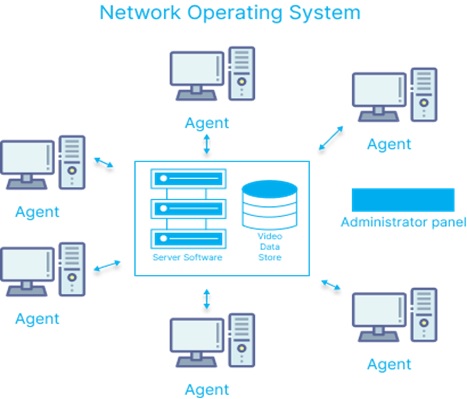

SCADA stands for Supervisory Control and Data Acquisition, and it refers to a category of industrial control systems that are used to monitor and control processes and equipment in industries such as manufacturing, energy, and water treatment. A SCADA system typically consists of a central host or server, remote terminal units (RTUs), programmable logic controllers (PLCs), sensors, and other devices that are distributed throughout a facility.

The primary function of a SCADA system is to collect and process data from sensors and other devices, and to provide a human-machine interface (HMI) that allows operators to visualize and control the process. SCADA systems are typically used to monitor and control a wide range of industrial processes, including manufacturing, transportation, and energy production.

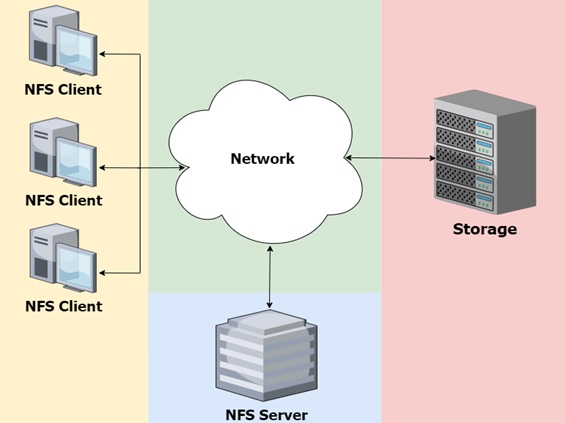

Figure 1. SCADA (Supervisory Control and Data Acquisition)

Some of the key features of SCADA systems include:

Real-time data acquisition: SCADA systems are designed to collect and process data from sensors and other devices in real-time, allowing operators to quickly detect and respond to process changes.

Remote monitoring and control: SCADA systems allow operators to monitor and control processes and equipment from a central location, reducing the need for on-site personnel.

Alarm notifications: SCADA systems can generate alarms and notifications based on predefined conditions, such as high or low process variables, equipment malfunctions, or other abnormal events.

Data logging and analysis: SCADA systems can log and store data over time, allowing operators to analyze trends and identify potential issues.

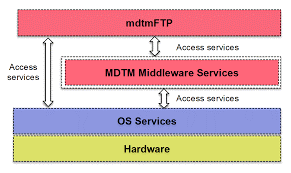

One of the key advantages of SCADA systems is their ability to integrate with other systems and technologies, such as enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and other automation technologies. This allows for more efficient and coordinated control of industrial processes, reducing costs and increasing productivity.

Overall, SCADA systems are a critical tool for managing and controlling industrial processes, providing real-time data acquisition and analysis, remote monitoring and control, and other advanced features that help ensure safe, efficient, and reliable operation of industrial facilities.

References:

- https://www.promotic.eu/en/pmdoc/WhatIsPromotic/WhatIsScada.htm

Cite this article:

Hana M (2023), SCADA (Supervisory Control and Data Acquisition), AnaTechMaz, pp.108