New durable material for flexible artificial muscle

Among many materials, dielectric elastomers (DE)—lightweight materials with high elastic energy density—have been of particular interest to be used in artificial muscles. That’s because they have optimal flexibility and toughness. Plus, they can be used as actuators, enabling machines to operate by transforming electric energy into mechanical work.

Most dielectric elastomers are made of silicone or acrylic; however, both have disadvantages. Traditional acrylic DEs lack flexibility and can only produce significant actuation strain after pre-stretching. Silicones can’t take a severe strain, but they are simpler to create. [1]

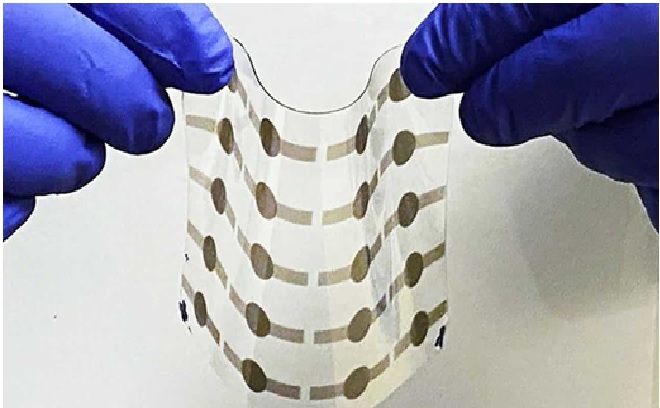

Figure 1. New durable material for flexible artificial muscle

Figure 1 shows utilizing commercially available chemicals and employing an ultraviolet (UV) light curing process, the UCLA-led research team created an improved acrylic-based material that is more pliable, tunable and simpler to scale without losing its strength and endurance. While the acrylic acid enables more hydrogen bonds to form, thereby making the material more movable, the researchers also adjusted the crosslinking between polymer chains, enabling the elastomers to be softer and more flexible. The resulting thin, processable, high-performance dielectric elastomer film, or PHDE, is then sandwiched between two electrodes to convert electrical energy into motion as an actuator. [2]

The UCLA research involves a "dry" process by which the films are layered using a blade and then UV-cured to harden, making the layers uniform. This increases the actuator's energy output so that the device can support more complex movements. [2]

Artificial muscles fitted with PHDE actuators can generate more force than biological muscles and they also demonstrate three to 10 times more flexibility than natural muscles. Multilayered soft films are usually manufactured via a "wet" process that involves depositing and curing liquid resin. However, that process can result in uneven layers, which make for a poor- performing actuator.

For this reason, up to now, many actuators have only been successful with single-layer DE films. The latest research involves a "dry" process by which the films are layered using a blade and then UV-cured to harden, making the layers uniform. [3]

The advance could lead to soft robots with improved mobility and endurance, and new technologies with a sense of touch. The manufacturing process could be used to make other soft thin-film materials. [4]

References:

- https://www.techexplorist.com/new-durable-material-flexible-artificial-muscle/52380/

- https://phys.org/news/2022-07-scientists-durable-material-flexible-artificial.html

- https://www.newsdrum.in/international/durable-material-for-flexible-artificial-muscles-developed-56357.html

- https://themasterchemistry.com/developement-of-durable-material-for-flexible-artificial-muscles/

Cite this article:

Thanusri swetha J (2022), New durable material for flexible artificial muscle, AnaTechMaz, pp.131