New Plastic Upcycling Technology: From Waste to Fuel for Less

A plastics recycling innovation that does more with less simultaneously increases conversion to useful products while using less of the precious metal ruthenium. It will be presented today at the American Chemical Society fall meeting in Chicago.“The key discovery we report is the very low metal load,” said Pacific Northwest National Laboratory (PNNL) chemist Janos Szanyi, who led the research team. “This makes the catalyst much cheaper.”

The new technique more efficiently converts plastics to valuable commodity chemicals—a process termed “upcycling.” Moreover, it produces much less methane, an undesirable greenhouse gas, as a byproduct, compared with other reported methods. [1]

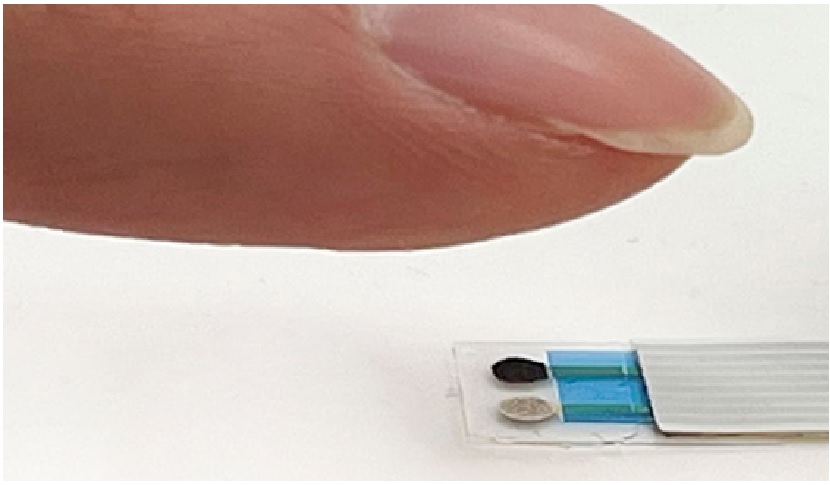

Figure 1. New Plastic Upcycling Technology: From Waste to Fuel for Less

Figure 1 shows Petroleum-based plastic waste presents an untapped source of carbon-based chemicals that can serve as the starting material for useful durable materials and fuels. Very little plastic is currently recycled, mainly for economic and practical reasons. But PNNL scientists are trying to change the dynamic by applying their expertise in efficiently breaking chemical bonds. [2]The research team discovered that reducing the amount of the precious metal ruthenium actually improved the polymer upcycling efficiency and selectivity.

Trapped atoms

A track record of PNNL expertise in single-atom catalysts helped the team understand why less is more. The research team observed the transition to disorder on the molecular level and then used established theory to show that single atoms are actually more effective catalysts in this experimental work.

The work builds on research in atom trapping and single-atom catalysts by Yong Wang, a professor of chemical engineering at Washington State University, Pullman, and a PNNL Laboratory fellow. [3]

Learning to tolerate chlorine

To make the method practical for use with mixed plastic recycling streams, the research team is now exploring how the presence of chlorine affects the efficiency of chemical conversion.

Specialist in industrial applications for catalysis, chemist Oliver Y. “We are looking for more demanding extraction conditions,” Gutierrez said. “When you don’t have a clean plastic source in an industrial upcycling process, you have chlorine from polyvinylchloride and other sources. Chlorine can contaminate the plastics upcycling reaction. We want to understand what chlorine has on our systems.” have an impact on.”

Now, that fundamental understanding could help convert waste plastics that usually end up in the environment as pollution into useful products. [4]

References:

- https://scitechdaily.com/new-plastic-upcycling-technology-from-waste-to-fuel-for-less/

- https://www.sciencedaily.com/releases/2022/08/220822130257.htm

- https://mixpoint.in/materials-science/2022/08/plastic-upcycling-from-waste-to-fuel-for-less/

- https://biz.crast.net/plastic-upcycling-from-waste-to-fuel-for-less/

Cite this article:

Thanusri swetha J (2022), New Plastic Upcycling Technology: From Waste to Fuel for Less, AnaTechMaz, pp.288