Promising Steps Towards High-speed Motors for Fuel Cell Components

The transport sector is transforming towards climate-friendly powertrains with significantly reduced CO2 emissions. The electrification of powertrains remains a major challenge not only for trucks, buses, trains, and ships but also for aircraft. These applications cannot be realized in the future with batteries because of the energy requirements. The fuel cell is an extremely promising energy supplier for these applications, which supplies electrical energy from stored hydrogen and ambient air. [1]

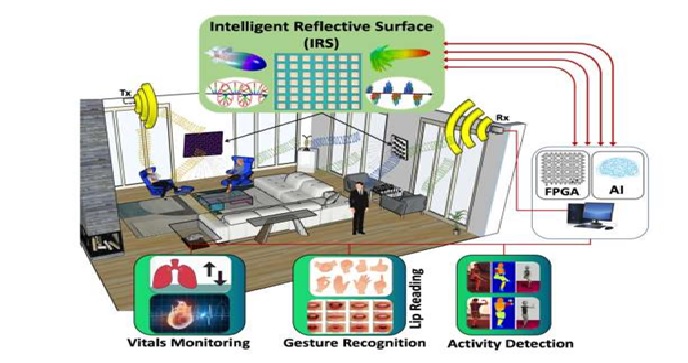

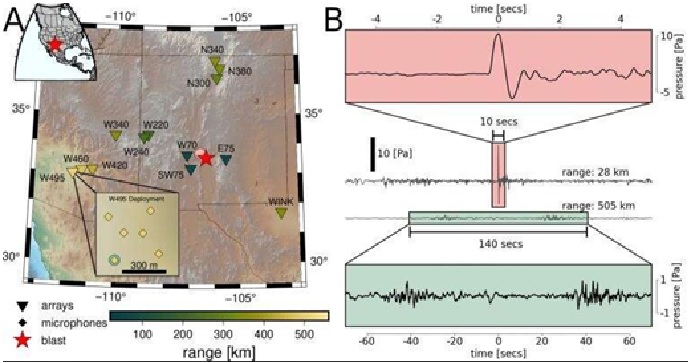

Figure 1. Promising Steps Towards High-speed Motors for Fuel Cell Components

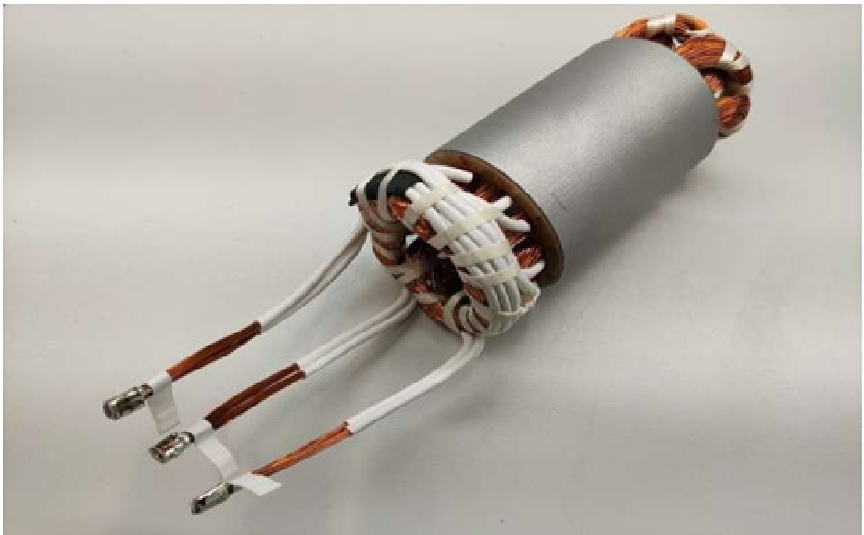

Figure 1 shows the Fraunhofer Institutes LBF, IFAM, IISB and SCAI have joined forces to develop advanced and highly efficient components for fuel cells. The HABICHT project aims to design and develop a high-speed engine for a fuel cell compressor for truck and aviation innovation. The electric machine must achieve at least a power density of 30 kW/kg by using innovative materials to directly cool the stator and maximize the speed capability of the rotor.[2]

Primarily based on the speedy definition of the specs, a viable idea for electromagnetic design has been developed with analytical and numerical assist. The work was carried out in interplay with structural-mechanical investigations on the velocity stability of the everlasting magnets in addition to with thermal investigations on the mandatory cooling capability, which is assured by the mix of cooling jacket, hole rotor shaft, and thermal connection of the winding head with a dielectric fluid. Inside HABICHT, Fraunhofer SCAI is answerable for multi-physics modeling and the setup of a sensible design surroundings for electrical engines. [3]

Future work: Optimization and benchmarking

The long run work is concentrated on optimization of the present working design and execution in a way appropriate for manufacturing. For this goal, decreased take a look at carriers are for use for stator winding, electrical insulation, banding, sheet metallic chopping, bonding, and magnet shaping, amongst different issues, previous to the development of the whole system. The forming of cooling channels shaped throughout potting is to be solved by way of course of and materials expertise primarily based on the literature research already carried out. The difference of the HABICHT machine to an current turbo compressor is to be realized with appropriate however on the identical time typical shaft and bearing expertise, whereby the frequency-dependent inherent dynamics of the mechanical transferring components are to be decided upfront. [4]

References:

- https://www.eletimes.com/promising-steps-towards-high-speed-motors-for-fuel-cell-components

- https://newjerseyupdates.com/first-steps-towards-high-speed-motors-for-fuel-cell-components/65209/

- https://thefastnewz.com/first-steps-toward-high-speed-motors-for-fuel-cell-components/

- https://car-ching.com/2022/07/first-steps-toward-high-speed-motors-for-fuel-cell-components/

Cite this article:

Thanusri swetha J (2022), Promising Steps Towards High-speed Motors for Fuel Cell Components, AnaTechMaz, pp.267